Direct air cooling method for shifted gas

A technology of air cooling and gas transformation, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of uneconomical, increased operating energy consumption, low gas density, etc., to save energy consumption and The effect of energy cost expense, saving of special facilities, and heat transfer coefficient improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

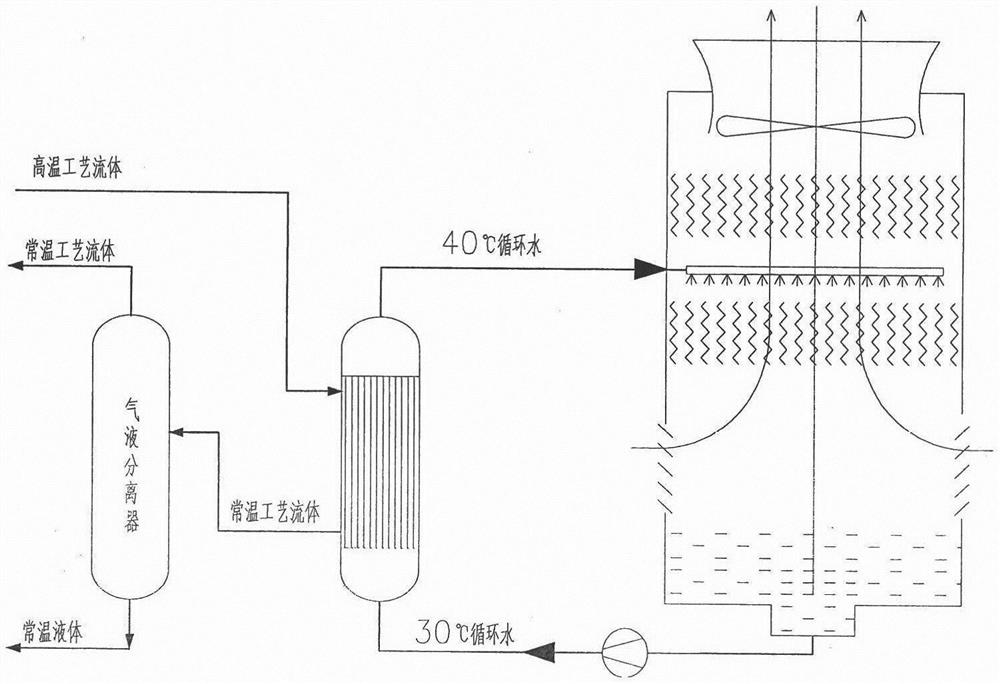

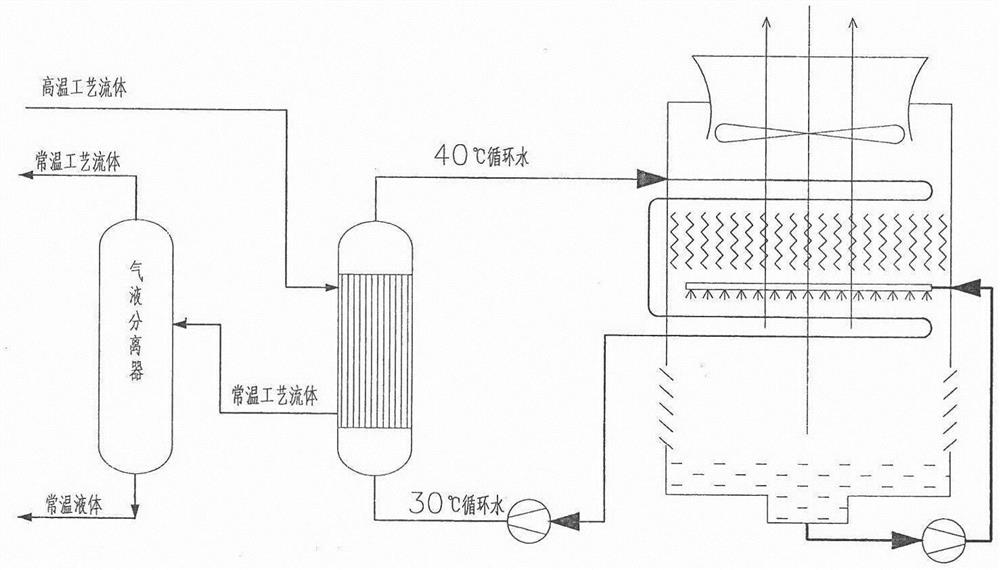

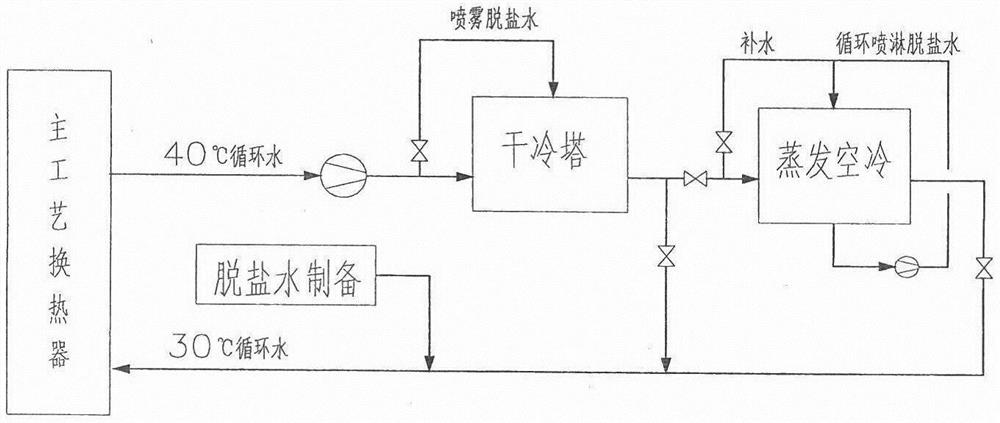

[0062] A coal chemical production line located in a water-scarce area is 1,300 meters above sea level, with a dew point temperature of 23°C and a high-temperature shift gas of 186,000Nm from the soft water preheater 3 / h, absolute pressure 6.5MPa, temperature 70°C, specific heat capacity 0.35kcal / Nm 3 °C, where the volume ratio of saturated water vapor content to dry shift gas is 100:0.7, and cooled down to ≤40 °C. Heat released by high temperature and humidity shift gas: 2383000 kcal / h.

[0063] The air cooler adopts a single tube pass, the resistance drop is ≤0.02MPa, and the windward area is 54m 2 , the wind speed is 2.5m / s, the power consumption of the fan is 22kw, the head of the circulating water pump is 20m, the circulating water volume is 8 tons / hour, and the power consumption is 1.0kw; due to the high pressure of the transformed gas, in order to prevent the leakage of the shaft seal, a magnetically driven shielded pump is used.

[0064] During the high temperature p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com