Atmospheric corrosion resistant martensitic wear-resistant steel plate and manufacturing method thereof

A technology for atmospheric corrosion-resistant and wear-resistant steel plates, applied in the field of iron and steel smelting, can solve the problems that the hardness, plasticity, toughness, wear resistance and corrosion resistance of steel plates cannot be taken into account at the same time, and achieve the effect of good low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

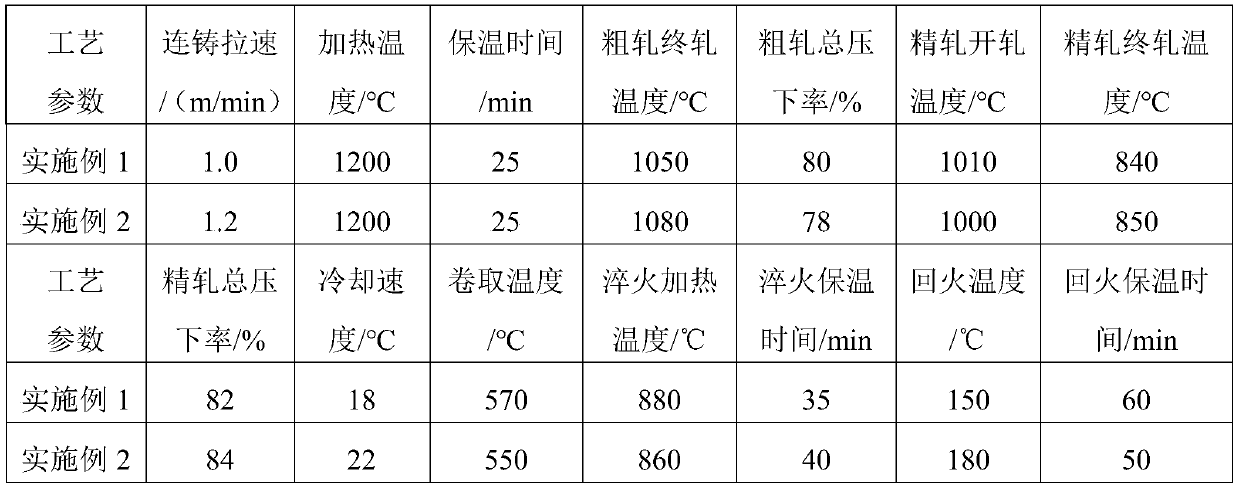

[0072] The preparation method of the steel plate described in embodiment 1~2 and comparative example comprises the following steps:

[0073] The molten steel is smelted in a 210-ton converter after desulfurization by KR, desulfurized by the KR method, smelted by the converter, refined by the RH method, and continuously cast into slabs, which are reheated, rough rolled, finish rolled, laminar cooled, and coiled into coils , the steel coils are successively treated by Kaiping, quenching and tempering to become a martensitic wear-resistant steel plate resistant to atmospheric corrosion, which can be spray-printed, packaged and put into storage.

[0074] Table 2

[0075]

Embodiment 1

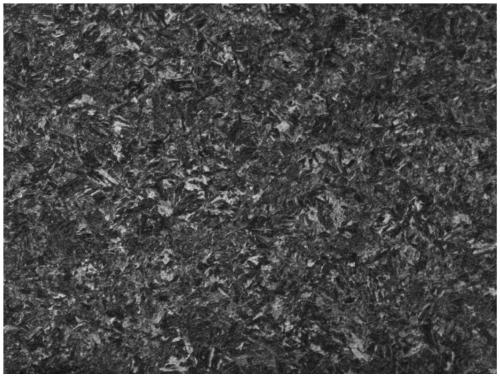

[0076] The thickness of the atmospheric corrosion-resistant martensitic wear-resistant steel plate described in Example 1 is 8mm, and its metallographic structure is as follows figure 1 as shown, figure 1 The metallographic structure of medium steel plate includes tempered martensite structure plus a small amount of carbide, and the steel plate has high wear resistance.

Embodiment 2

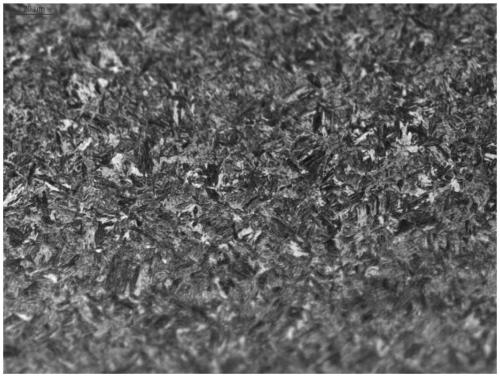

[0077] The thickness of the atmospheric corrosion-resistant martensitic wear-resistant steel plate described in embodiment 2 is 8mm, and its metallographic structure is as follows figure 2 as shown, figure 2 The metallographic structure of medium steel plate includes tempered martensite structure plus a small amount of carbide, and the steel plate has high wear resistance.

[0078] The specific mechanical properties of each embodiment and comparative examples are shown in Table 3.

[0079] table 3

[0080]

[0081] The yield strength of the atmospheric corrosion-resistant martensitic wear-resistant steel plates described in Examples 1-2 are all greater than 1100 MPa, and the tensile strength is greater than 1400 MPa. The elongation after breaking is greater than 10%, and the impact energy at -40°C is greater than 27J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com