Rock powder shaped emulsion explosive and manufacturing method thereof

A technology for powder emulsion explosive and manufacturing method, which is applied to explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of inconvenient storage and use, waste of manpower and material resources, and increase of production costs, etc. Achieve the effect of improving storage stability, eliminating human and environmental hazards, and reducing dissolution and emulsification temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1 (taking the preparation of 500 kilograms of rock powdery emulsion explosives as an example). The mass percentages of each component of the rock powdery emulsion explosive are selected as follows: 90% ammonium nitrate, 1% urea, 3% water, 1.2% paraffin, 1.2% microcrystalline wax, 1.6% rosin, and 2.0% polymer emulsifier. Accurately weigh 450 kg of ammonium nitrate, 5 kg of urea, 15 kg of water, 6 kg of paraffin, 6 kg of microcrystalline wax, 8 kg of rosin, and 10 kg of polymer emulsifier according to the above proportioning ratio.

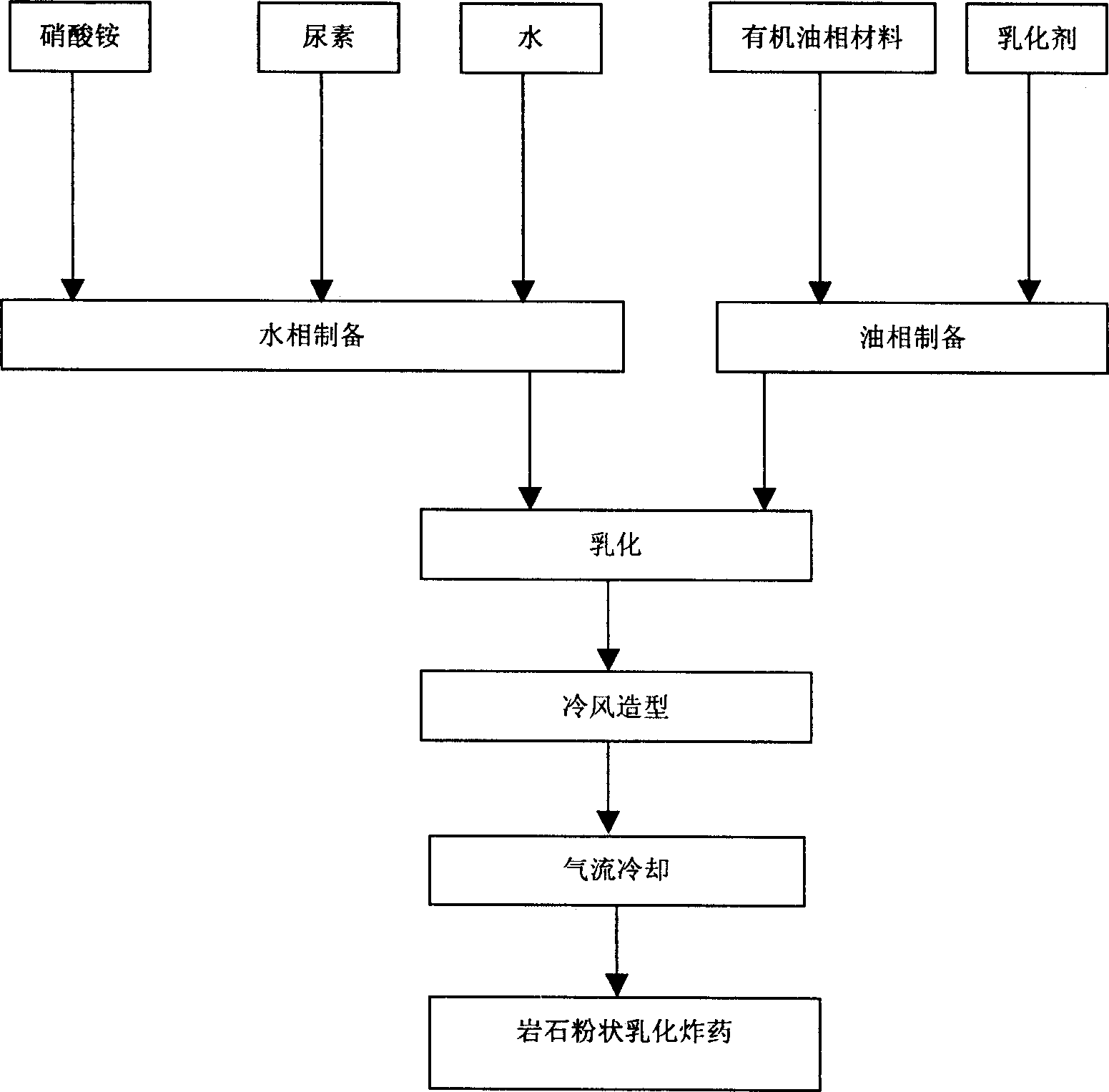

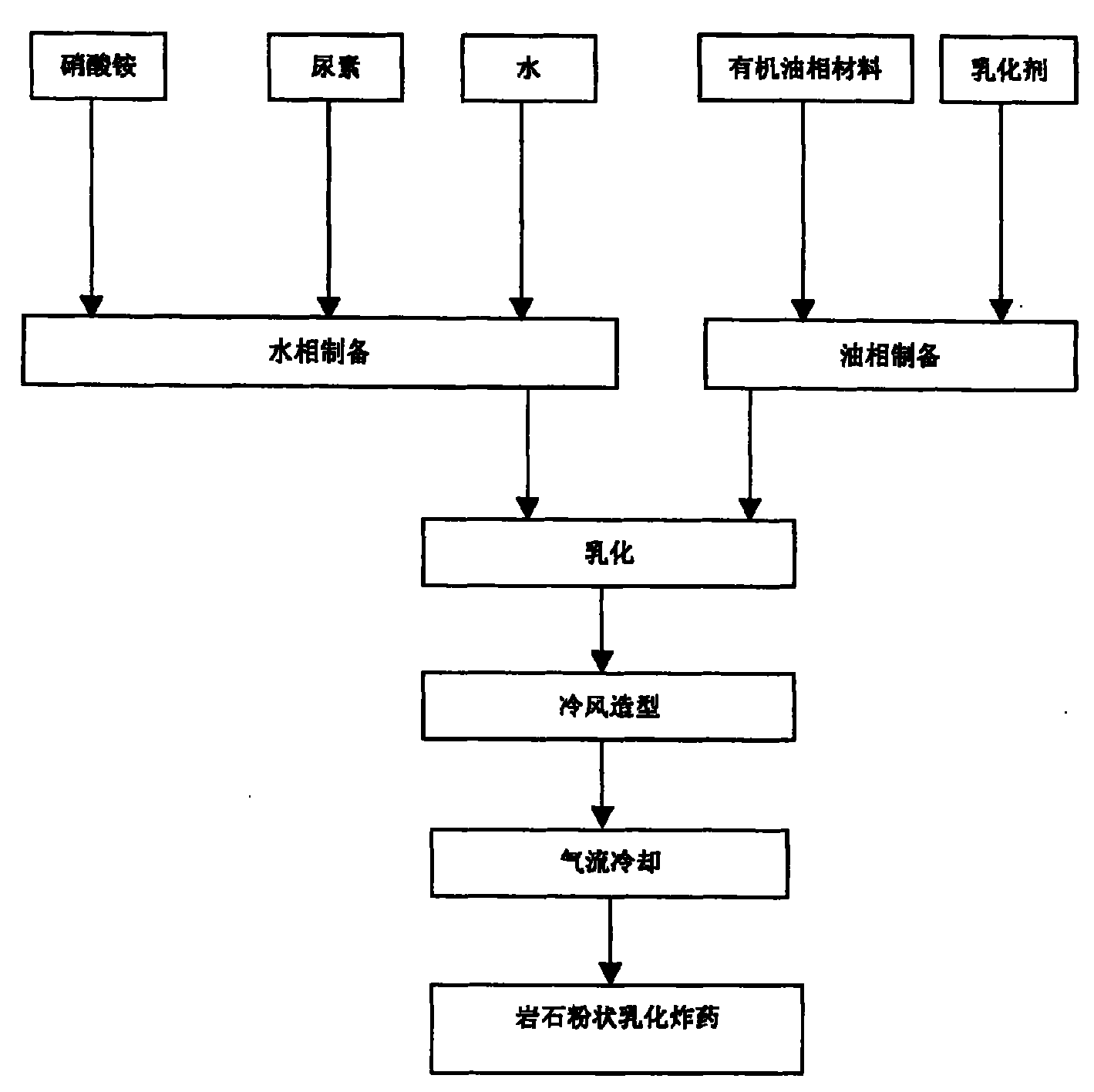

[0011] Operation steps: in the first step, heat and dissolve ammonium nitrate, urea and water and raise the temperature to 135°C; Phase and oil phase materials are emulsified into latex through an emulsifier; in the fourth step, the latex obtained in the third step is molded by cold air through a three-fluid nozzle, and the rock powdery emulsion explosive is directly produced. In the fifth step, the rock powdery emulsion explosive...

Embodiment 2

[0012] Embodiment 2 (taking the preparation of 500 kilograms of powdery emulsion explosives as an example). The mass percent of each component of rock powdery emulsion explosive is selected as follows: 89 ammonium nitrate, 2 urea, 3 water, 2.0 paraffin, 1.0 microcrystalline wax, 0.6 rosin, and 2.4 polymer emulsifier. Accurately weigh 445 kg of ammonium nitrate, 10 kg of urea, 15 kg of water, 10 kg of paraffin, 5 kg of microcrystalline wax, 3 kg of rosin, and 12 kg of polymer emulsifier according to the above proportioning ratio. The operating steps and test conditions are the same as in Example 1. The measured explosive performance is: detonation velocity 4650m / s, brute force 18mm, working capacity 332ml, and detonation distance 17cm.

Embodiment 3

[0013] Embodiment 3 (taking the preparation of 500 kilograms of powdery emulsion explosives as an example). The mass percent of each component of the rock powder emulsion explosive is: ammonium nitrate 88, urea 3, water 3, paraffin 1.6, microcrystalline wax 1.2, rosin 1.0, polyethylene 0.4, polymer emulsifier 1.8. Accurately weigh 440 kg of ammonium nitrate, 15 kg of urea, 15 kg of water, 8 kg of paraffin, 6 kg of microcrystalline wax, 5 kg of rosin, 2 kg of polyethylene, and 12 kg of polymer emulsifier according to the above proportioning ratio. The operating steps and test conditions are the same as in Example 1. The measured explosive performance is: detonation velocity 4400m / s, brute force 16mm, working capacity 345ml, and detonation distance 17cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com