Device for automatically conveying reserved bottom threads and embroidering machine

An automatic conveying device and automatic conveying technology, applied in the field of embroidery machines, can solve the problems of affecting work efficiency, time-consuming, frequent replacement of spare bottom threads by workers, etc., and achieve the effect of liberating labor force and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

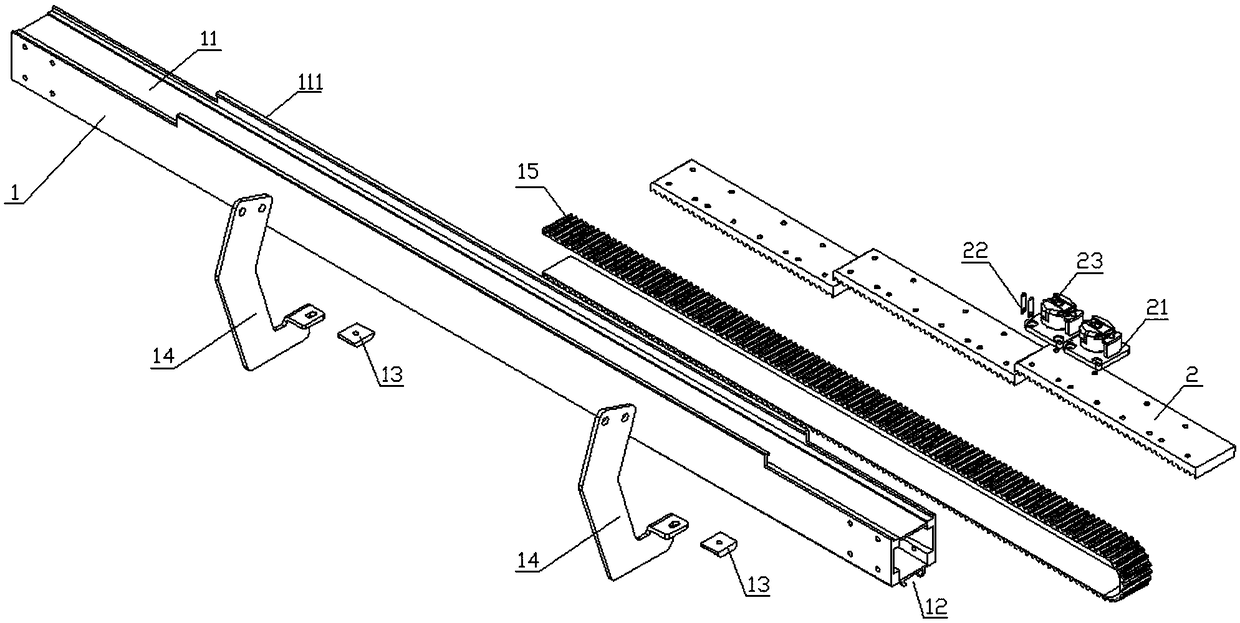

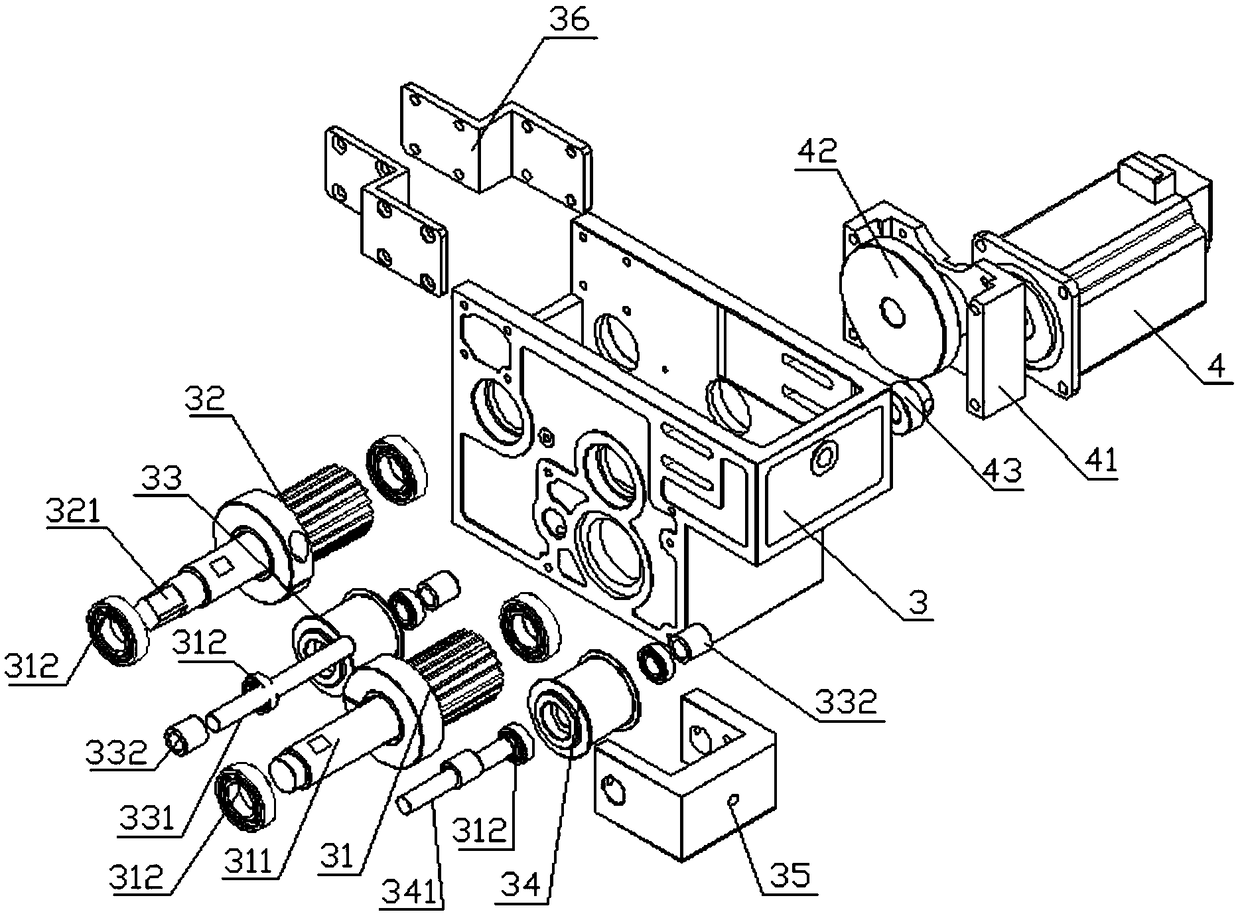

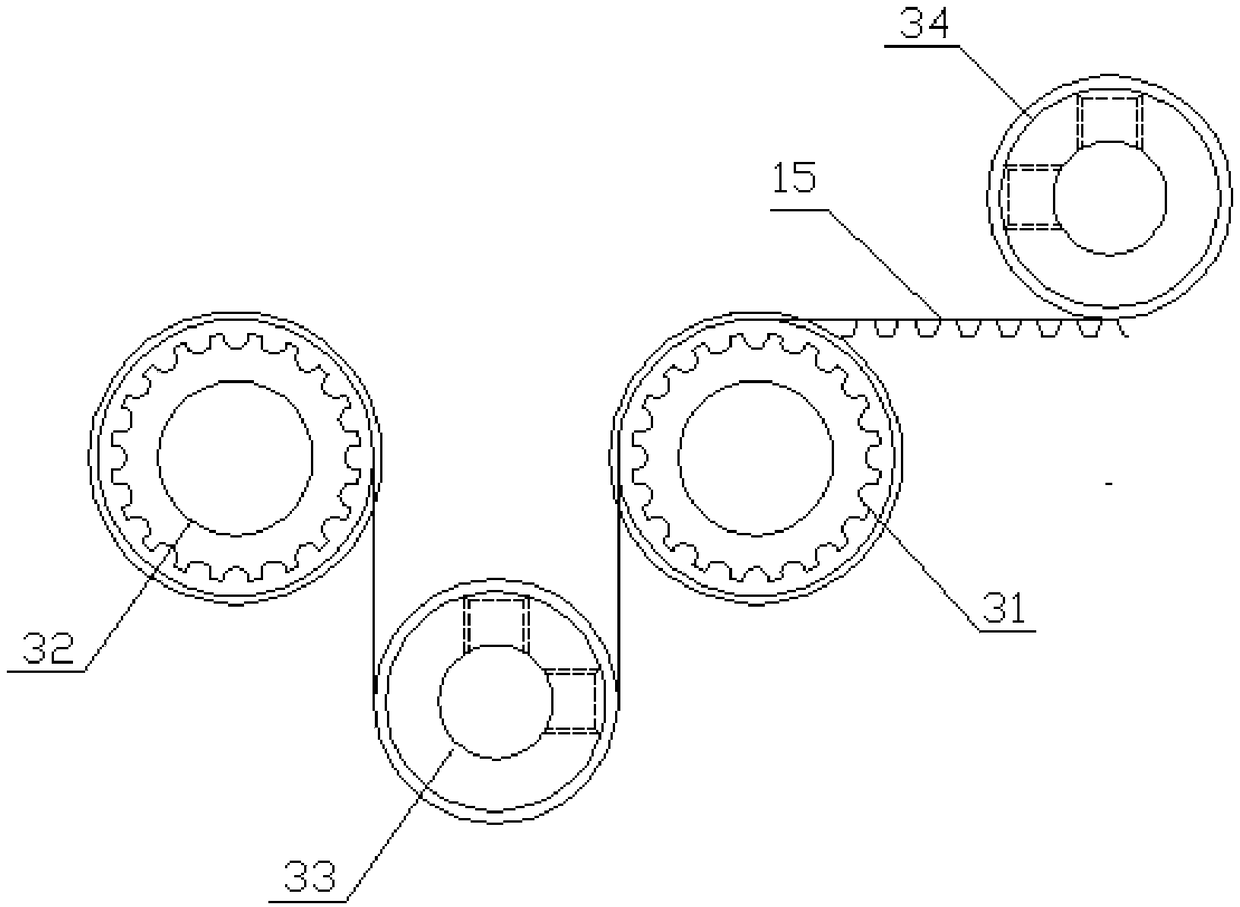

[0023] Embodiment one, refer to Figure 1 to Figure 3 As shown, a device for automatically conveying a spare bottom thread includes a transmission pulley base 1, a transmission belt 15 running on the transmission pulley base 1, a transmission pulley box 3 for driving the transmission belt 15 to run, and a transmission drive for inputting power to the transmission pulley box 3. The motor 4, the transmission belt 15 is connected with several bottom thread holder mounting plates 2, and the bottom thread holder installation plate 2 is provided with at least two bottom thread holders 21 for placing the bottom thread along the running direction of the transmission belt 15. Bottom thread stand mounting plate 2 can adopt steel plate, plastic plate or rubber plate etc. The transmission drive motor 4 works to make the transmission pulley box 3 drive the transmission belt 15, and the bobbin thread holder mounting plate 2 moves a certain distance with the conveyance belt 15, so that the s...

Embodiment 2

[0033] Embodiment 2, the embroidery machine includes the above-mentioned device for automatically feeding the spare bobbin thread, which automatically supplies the spare bobbin thread for all heads of the embroidery machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com