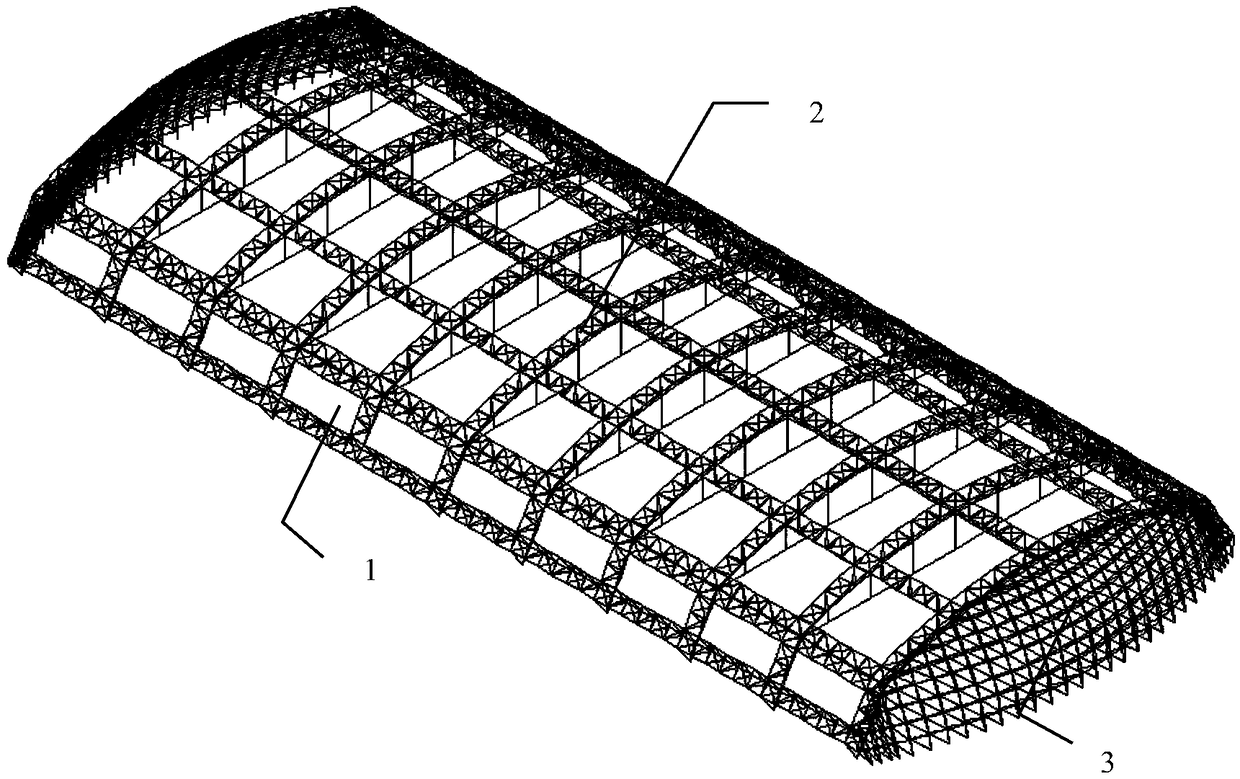

Large-span rigid gable space grid-three-sections composite cable arch (truss)-membrane structure system

A space grid, large-span technology, applied in the direction of arched structure, dome roof structure, building components, etc., can solve the problem of reducing the total cost of engineering construction, achieve multiple load transfer paths, easy to manufacture and install, architectural modeling beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation includes the following steps:

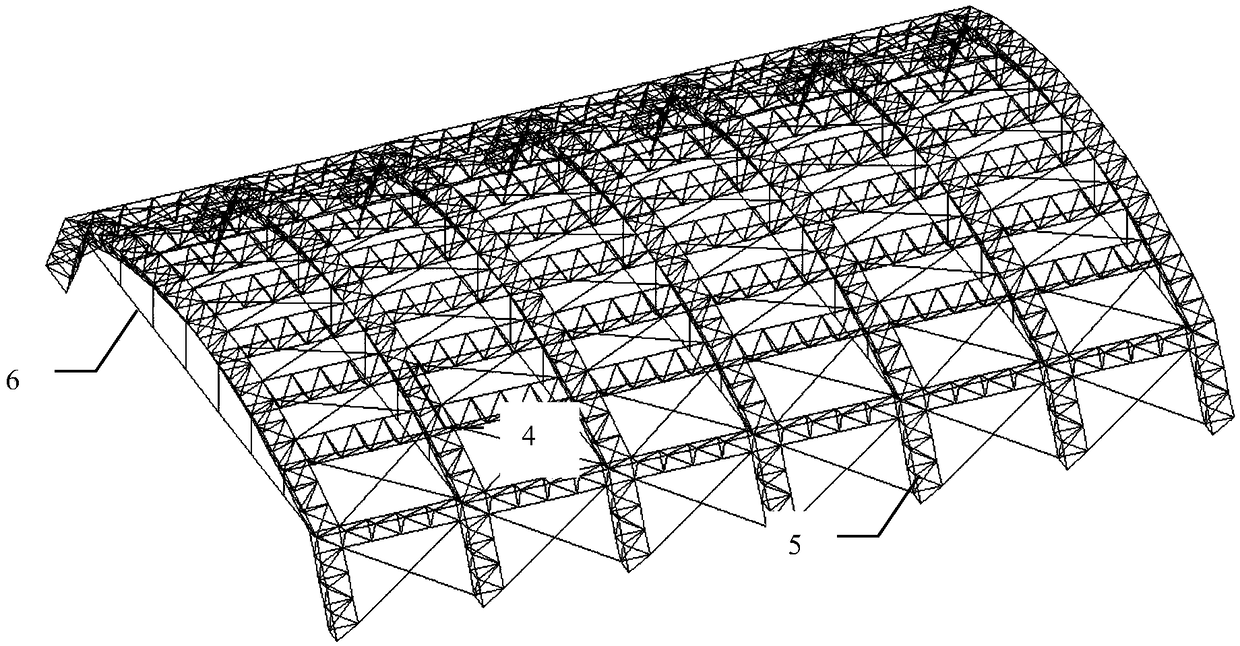

[0020] All components of the middle three-section combined cable-arch truss structure (2) should be processed in the factory to ensure the accuracy of cutting and the quality of welds. When the components are transported to the construction site, it is recommended that the ground is assembled in blocks, hoisted in blocks, and spliced to minimize high-altitude operations.

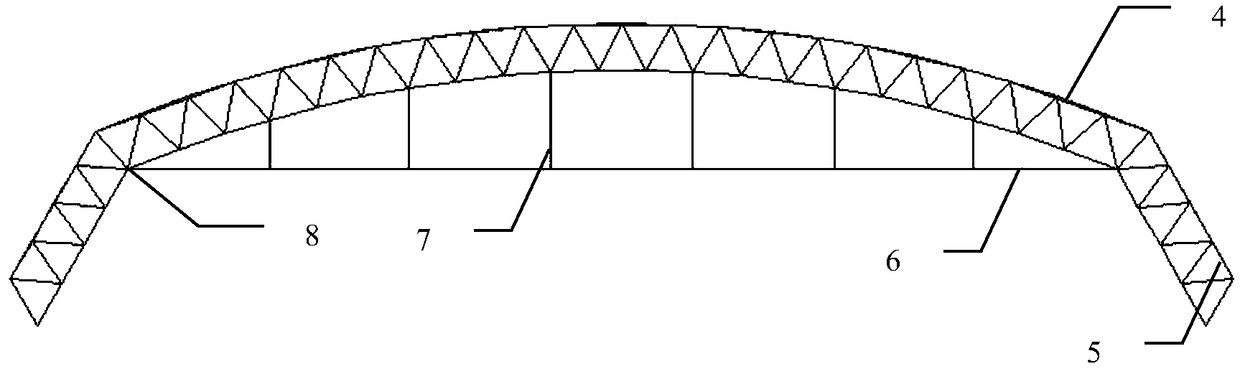

[0021] The supporting cable system is composed of a lower cable (6) and a straight web rod (7). The lower cable (6) and straight web rod (7) are all prefabricated in the factory and shipped to the site for installation.

[0022] Install the cable (6). Fix one end of the stay cable to the lower chord end node of the middle arch truss of the three-segment composite truss structure, and temporarily fix the cable body at the node (8). At this time, the cable is not clamped to ensure that the cable can slide smoothly . The tension tool is used to pull the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com