Fireproof heat preservation board

A technology of fire-proof insulation board and insulation board, which is applied in the direction of heat preservation, fire protection, building components, etc. It can solve the problems of not having the ability to extinguish or reduce the fire, not being flammable, and being unable to isolate the fire source, etc., to achieve the effect of strengthening heat insulation , Strengthen its own strength, strengthen the effect of noise reduction and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

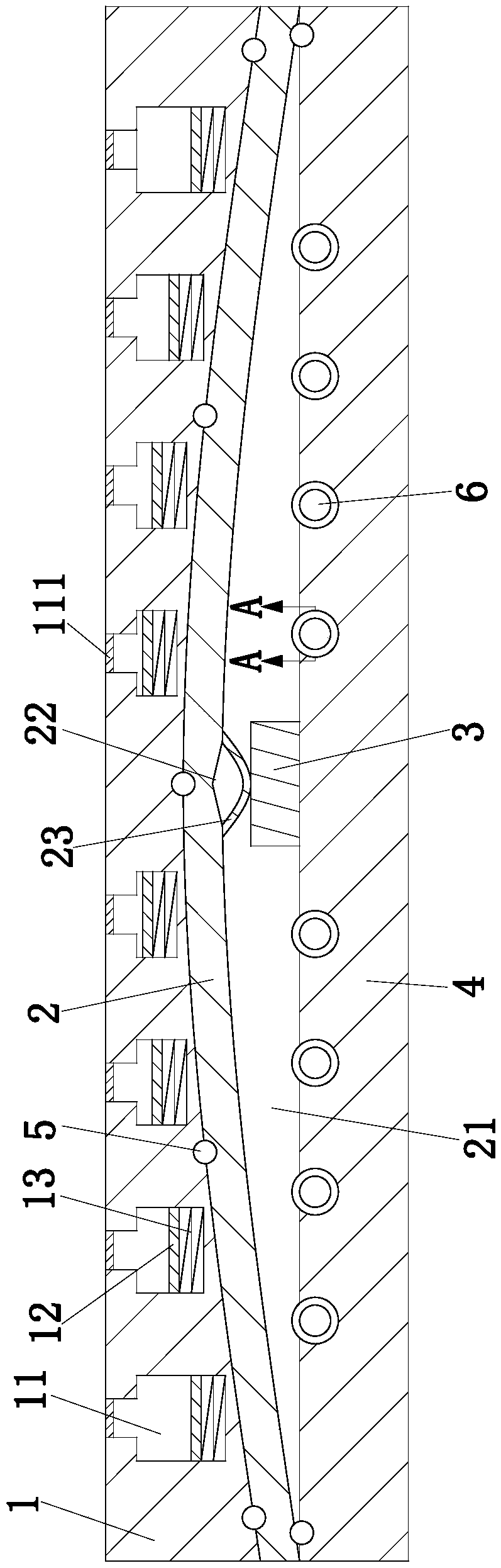

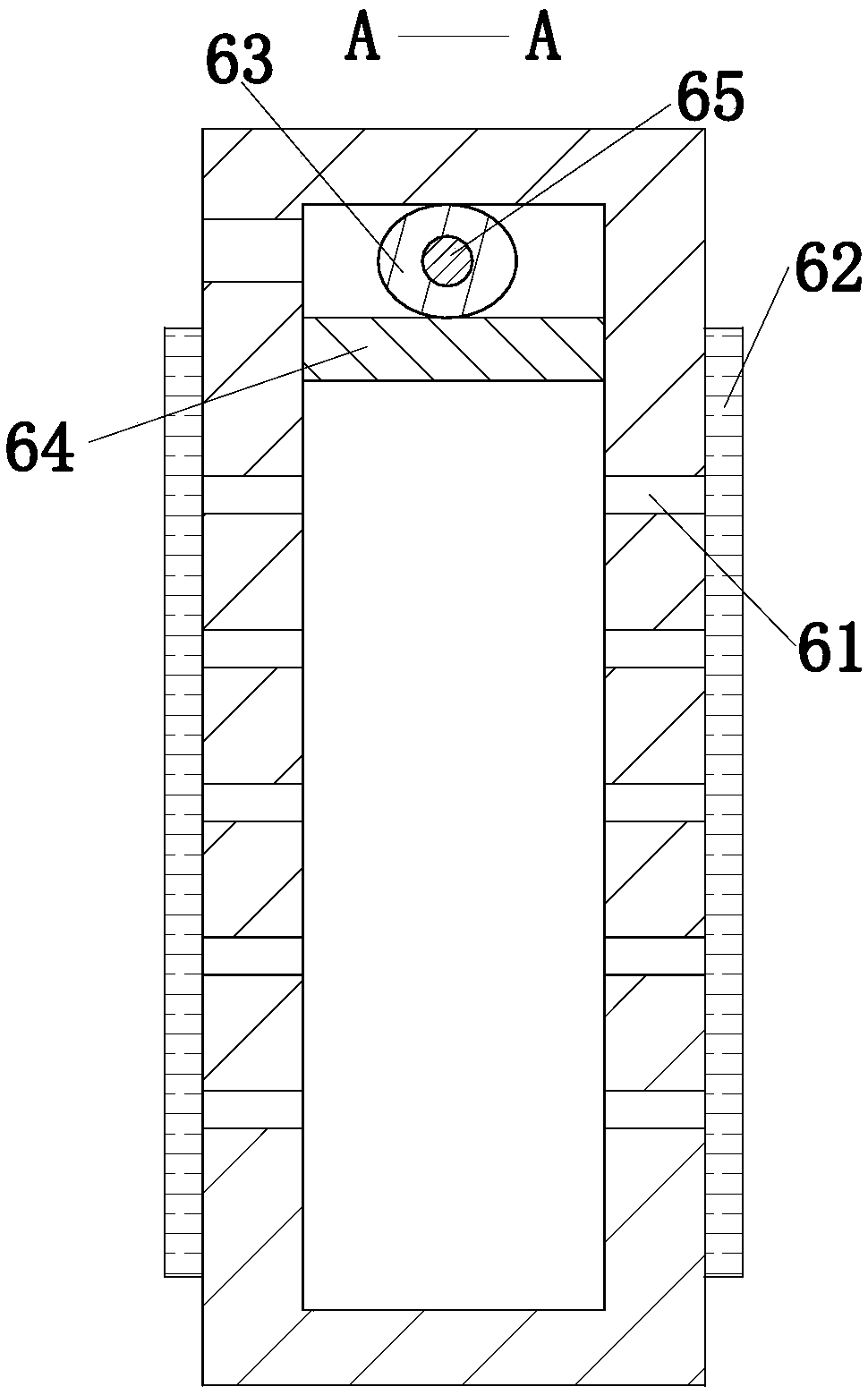

[0020] use figure 1 and figure 2 A kind of fire insulation board of the present invention is described as follows.

[0021] like figure 1 As shown, a kind of fireproof insulation board of the present invention comprises foam insulation board 1, fireproof rubber board 2, top block 3, steel plate 4 and hot melt adhesive-5, and described steel plate 4 is fixed on the ground or wall; The fireproof rubber plate 2 is located between the foam insulation board 1 and the steel plate 4, and the fireproof rubber plate 2 is coated with a fireproof layer; Bonded together, and the surface of the foam insulation board 1 and the fireproof rubber plate 2 is an arc surface; the top block 3 is located in the middle of the fireproof rubber plate 2 and the steel plate 4, and the top block 3 is used to withstand the fireproof rubber plate 2 The fireproof rubber plate 2 is bent under pressure, so that a cavity 21 is formed between the fireproof rubber plate 2 and the steel plate 4. After the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com