Mixed bridge plug

A hybrid bridge and mandrel technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of bridge plug residues at the bottom of the well, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

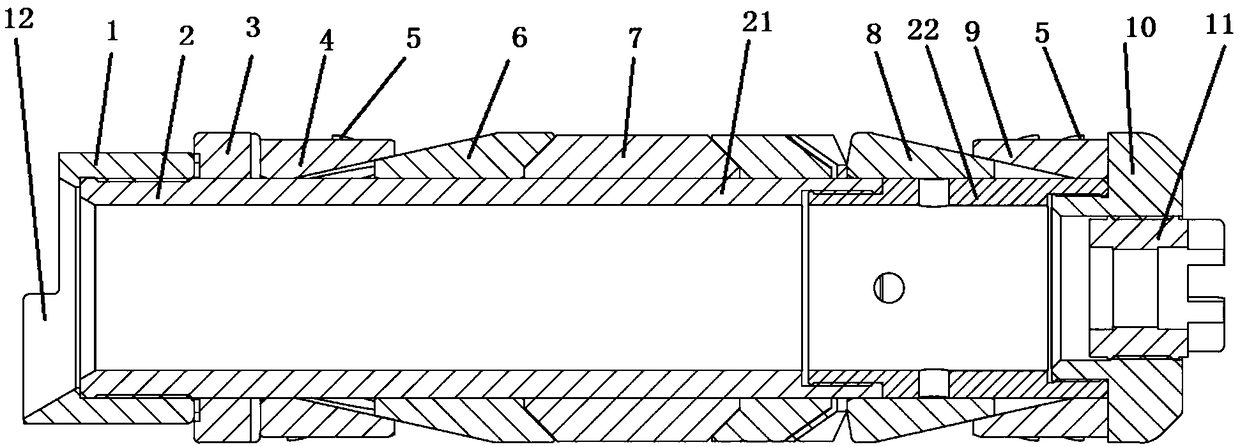

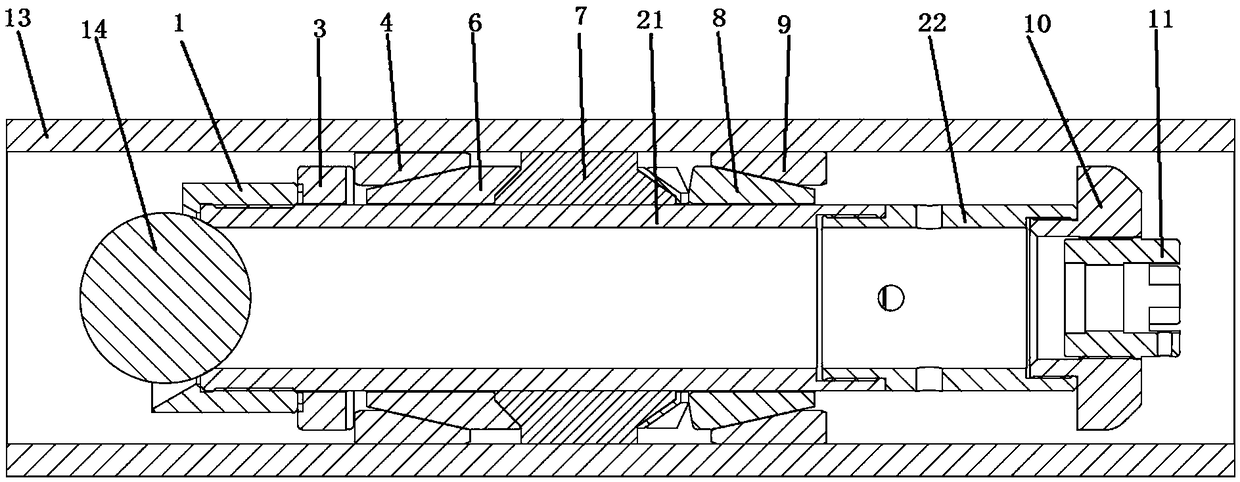

[0034] A schematic cross-sectional view of a hybrid bridge plug according to an embodiment of the present invention can be found in figure 1 , used for temporary plugging of oil and gas wellbore, including hollow mandrel 2 and rubber sleeve 7, rubber sleeve 7 is slidably sleeved on the middle of the outer surface of mandrel 2, and the outer surface of mandrel 2 is located at one end of rubber sleeve 7 in turn The first cone sleeve 8 and the first slip seat limiting structure 9 are sleeved, and the first joint 10 is sleeved on one end of the mandrel 2; There is a second cone sleeve 6 and a push ring 3, and the other end of the mandrel 2 is provided with a second joint 1; the mandrel 2, the first cone sleeve 8, the first slip seat limiting structure 9, the push ring The ring 3, the second cone sleeve 6, the first joint 10 and the second joint 1 are all m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com