Integrated water tank for cooler

A radiator and integrated technology, applied in the direction of machine/engine, engine components, engine cooling, etc., can solve inconvenience and other problems, achieve the effect of reducing the amount of solder used, saving welding costs, and eliminating welding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing an integrated water tank for a radiator, comprising the following steps:

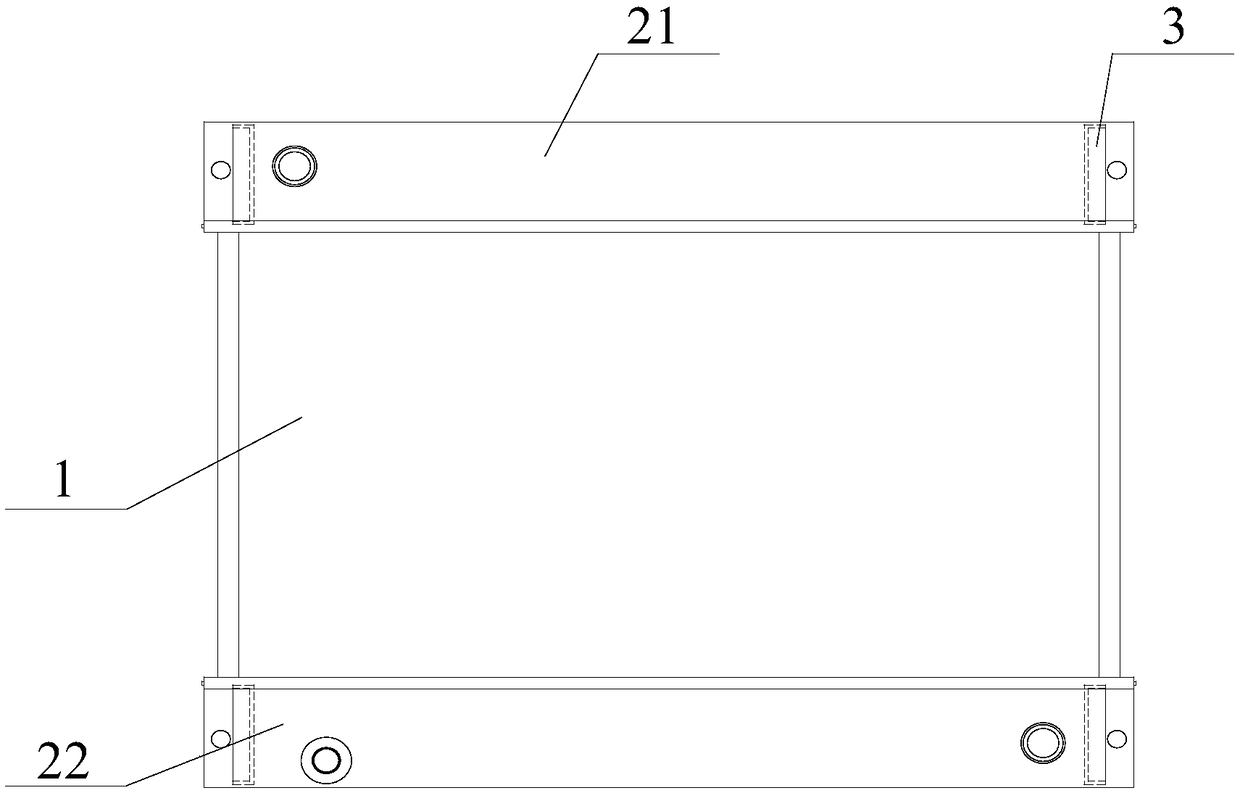

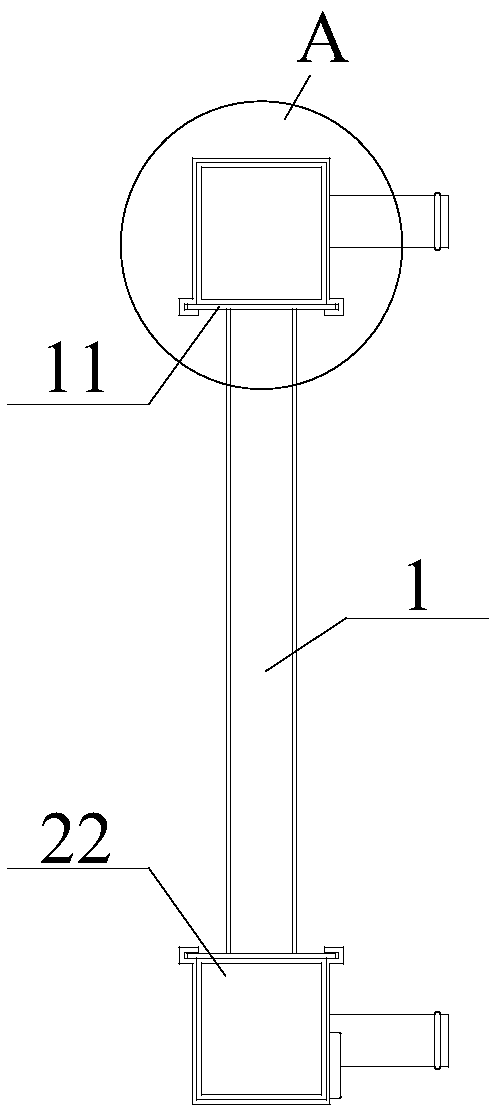

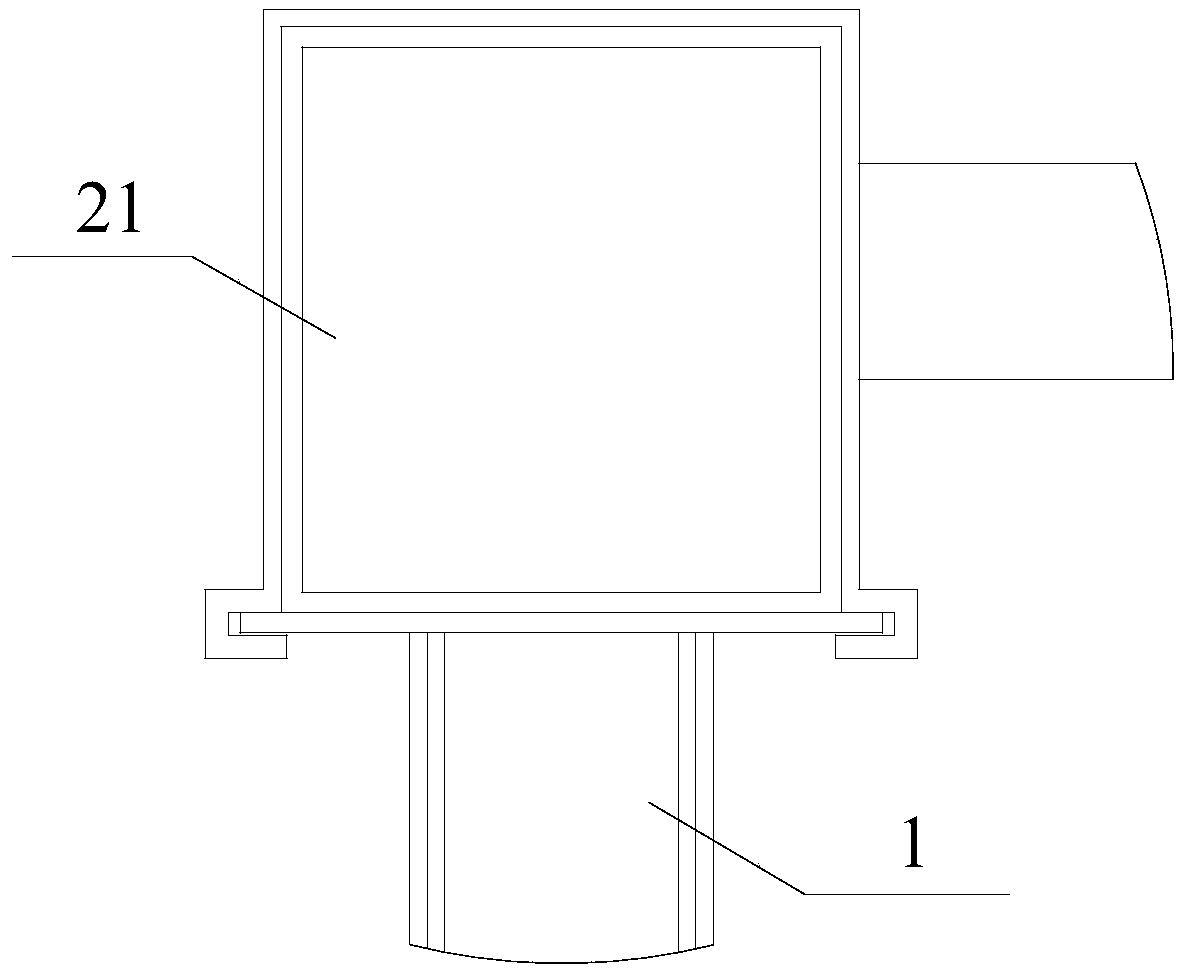

[0037] A. Process the water chamber so that its lower end has a draw-in groove 23, which is a U-shaped draw-in groove;

[0038] B. Process both ends of the core body 1 so that it has a main piece 11 corresponding to the U-shaped slot, and there is solder on the main piece 11, and the core body 1 is clamped with the water chamber to make the main piece 11 The part 11 of the piece is matched with the U-shaped card slot, and since there is solder on the part 11 of the main piece, and the solder is located at the upper and lower ends of the part 11 of the main piece, when the part 11 of the main piece is matched with the U-shaped card slot There is sufficient solder between the U-shaped slot and the contact surface of the main piece 11 of the core body 1 , and the width of the slot 23 is 0.3 mm to 0.5 mm larger than the thickness of the main piece 11 . There is solder on both ...

Embodiment 2

[0048] A method for preparing a plate-fin radiator by using a continuous brazing furnace, comprising the following steps:

[0049] A. Raw material preparation: According to the parameters of the core body 1, prepare the heat dissipation pipe 42, the outer fin 44, the outer fin seal 43, the solder sheet 41, and the reinforcement plate 45;

[0050] B. Cleaning of raw materials: Put the outer fin 44 and the outer fin seal 43 in an ultrasonic cleaning tank. There is LT-1 special cleaning agent for aluminum products in the ultrasonic cleaning tank to remove oil stains on the surface of parts. After cleaning, dry it for later use. The ratio of cleaning agent: water: LT-1 cleaning agent = 30:1;

[0051] C. Assembly of core body 1: such as Figure 7 As shown, on the assembly table, place the reinforcing plate 45 first, then place the outer fin 44, wrap the solder sheet 41 on the outer fin seal 43, and place the outer fin seal 43 covering the solder sheet 41 on the outer fin At the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com