A swash plate hydraulic axial piston pump/motor heavy-duty slipper pair anti-friction disc

An axial piston pump and swash plate type technology, which is applied in the field of swash plate hydraulic axial piston pump/motor heavy-duty slipper pair anti-friction disc, which can solve the problem of being sensitive to influence and difficult to satisfy slipper pair friction lubrication. Bearing performance design requirements and other issues to achieve the effect of reducing frictional power loss, easy maintenance and replacement, and sufficient lubrication and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

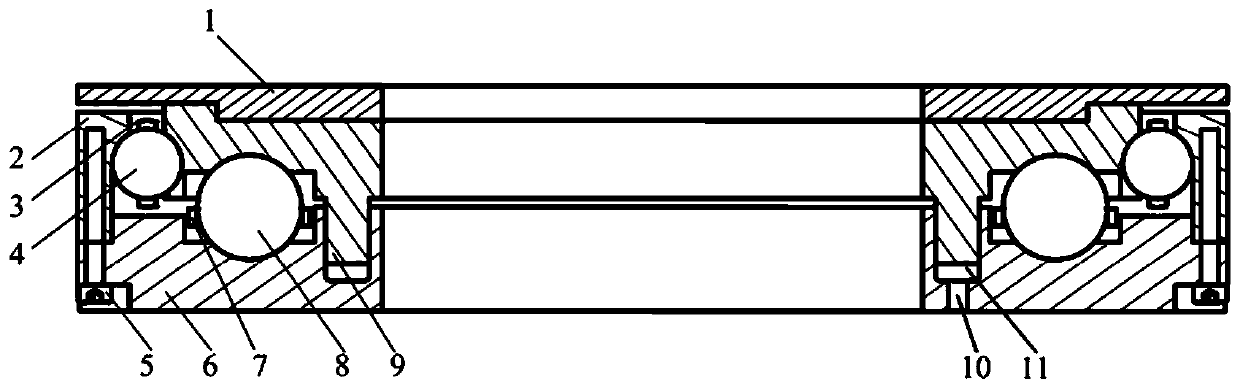

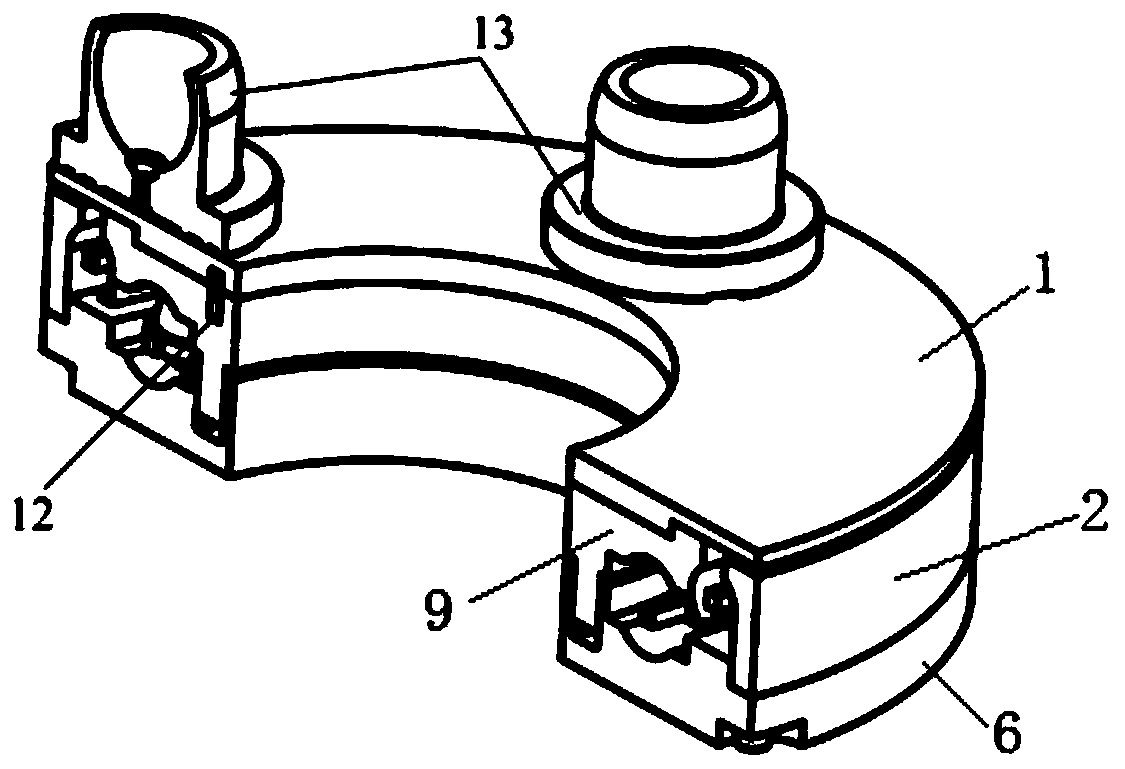

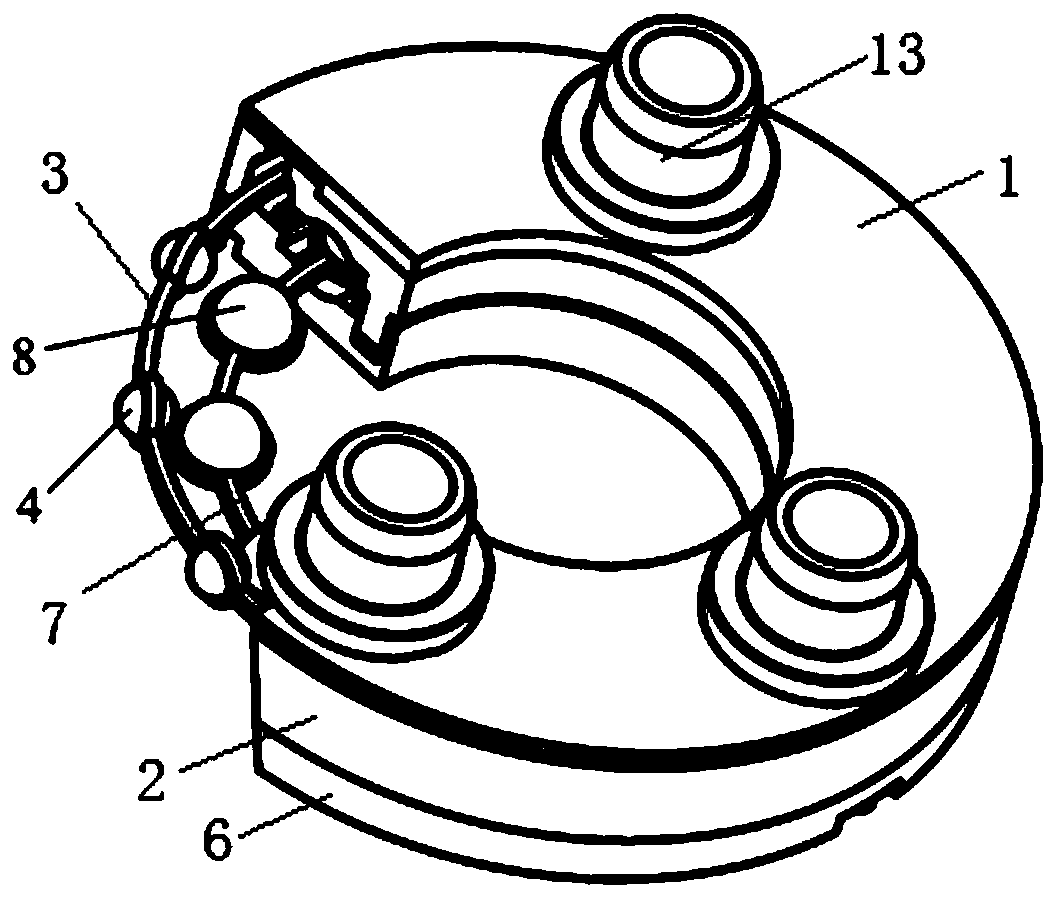

[0021] Such as figure 1 , 2 , 3 and 4, a swash plate hydraulic axial piston pump / motor heavy-duty slipper pair anti-friction disc is characterized in that it includes a rotating disc 1, a side cover 2, a base 6, an intermediate body 9, and a side 4 balls, 3 side cages, 8 bottom balls, 7 bottom cages. The rotating disk 1 is fixedly connected with the intermediate body 9 through pins 12 and interference fit. The side of the intermediate body 9 has a raceway for the side balls 4 to roll, and the bottom surface has a raceway for the bottom balls 8 to roll; the bottom ball 8 Installed between the raceway on the bottom surface of the intermediate body 9 and the raceway on the top surface of the base 6, the bottom surface cage 7 evenly separates the bottom surface balls 8 from each other, so that each bottom surface ball 8 is normally between the intermediate body 9 and the base 6 ground rolling; the side balls 4 are installed between the raceway of the side cover 2 and the side ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com