Oil-gas separator

A technology of oil-gas separator and separator, which is applied in the direction of separation method, dispersed particle separation, machine/engine, etc., which can solve the problems of oil-gas separator layout influence, vehicle modification space compression, etc., to reduce the difficulty of design and modification and installation height The effect of reducing requirements and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

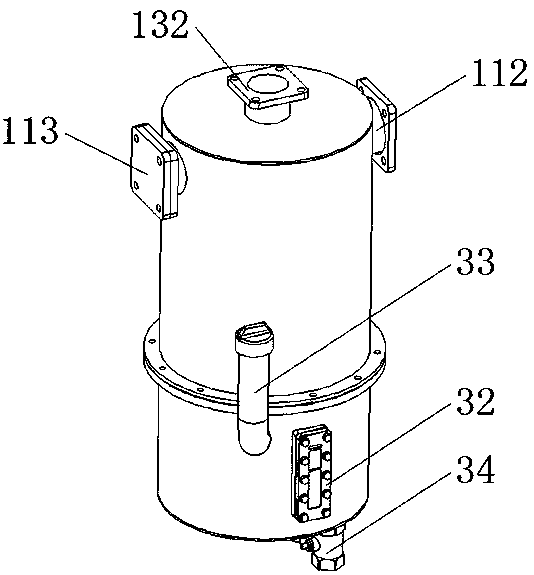

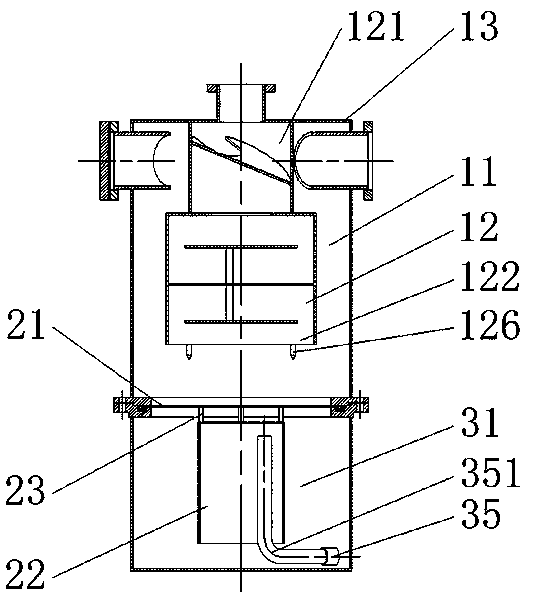

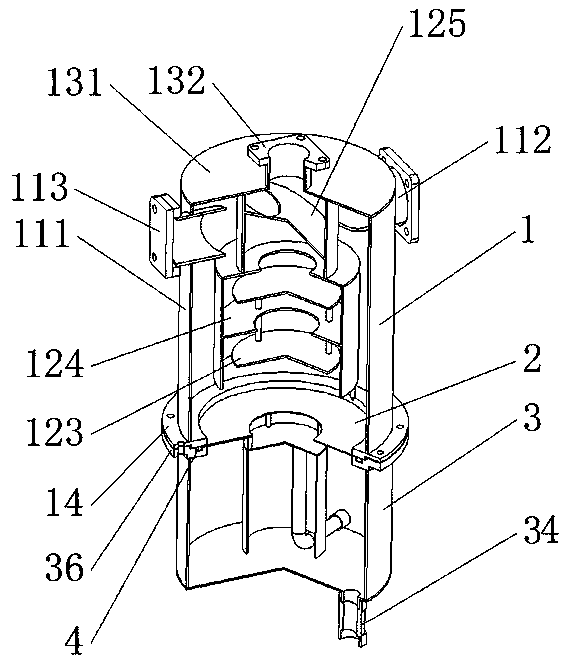

[0023] The oil-gas separator of the present embodiment, as figure 1 , figure 2 and image 3 As shown, it includes: a separator main body 1, an isolation disc 2 and an oil storage cylinder 3 arranged in sequence from top to bottom.

[0024] The separator main body 1 includes an outer cylinder 11, an inner cylinder 12 arranged in the outer cylinder 11, an upper cover 13 covering the tops of the outer cylinder 11 and the inner cylinder 12, and an upper connecting plate 14 arranged at the bottom of the outer cylinder 11, the outer cylinder 11 and the inner cylinder 12 is connected by an upper cover 13, and the inner cylinder 12 is arranged coaxially with the outer cylinder 11; two air intake pipes 112 are arranged symmetrically on the upper side of the outer cylinder 11, one of which is covered with a blind flange 113 to close it, and the other is used for connecting The air outlet of the vacuum pump and the two inlet pipes 112 are provided with oblique openings in the outer cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com