Vertical rotary filter

A vertical rotary and filter technology, which is used in filtration separation, moving filter element filters, separation methods, etc., can solve the problems of high installation height requirements, small effective filtering area, and difficulty in accessing the Internet on the filter layer, and can meet the installation height requirements. Low height, less auxiliary equipment and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

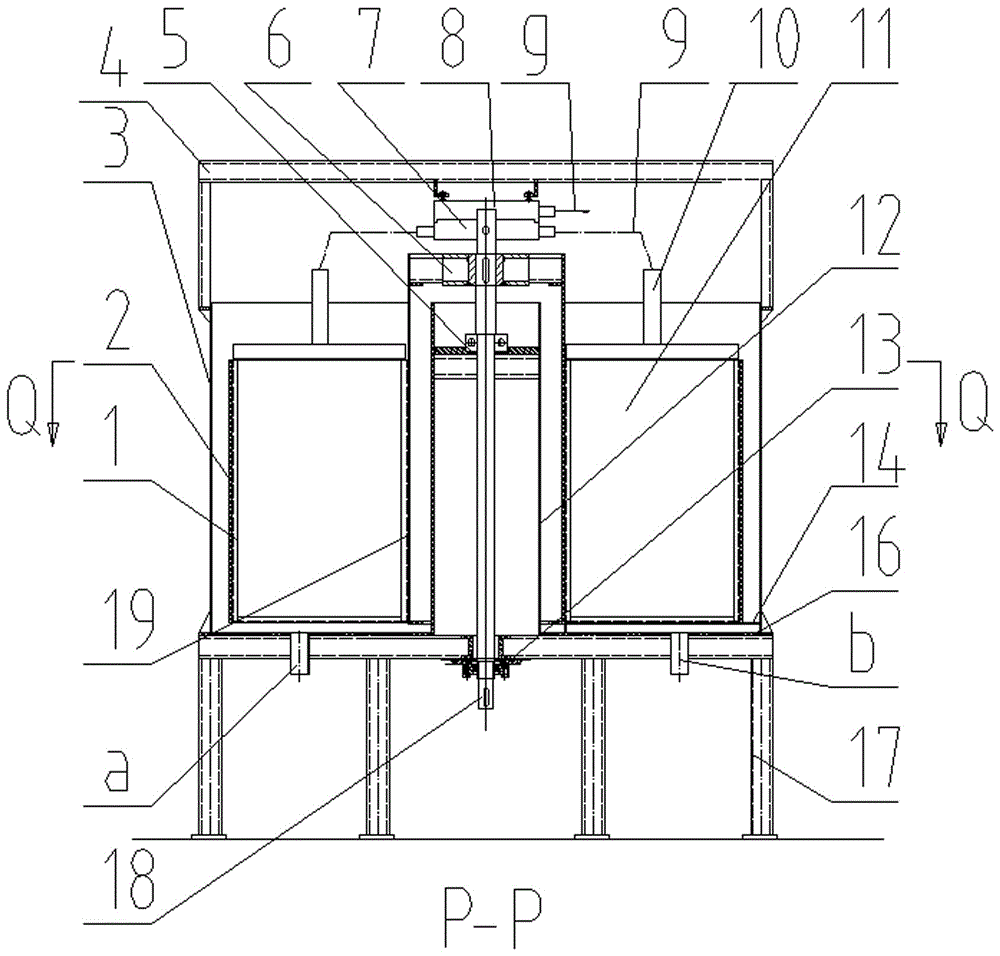

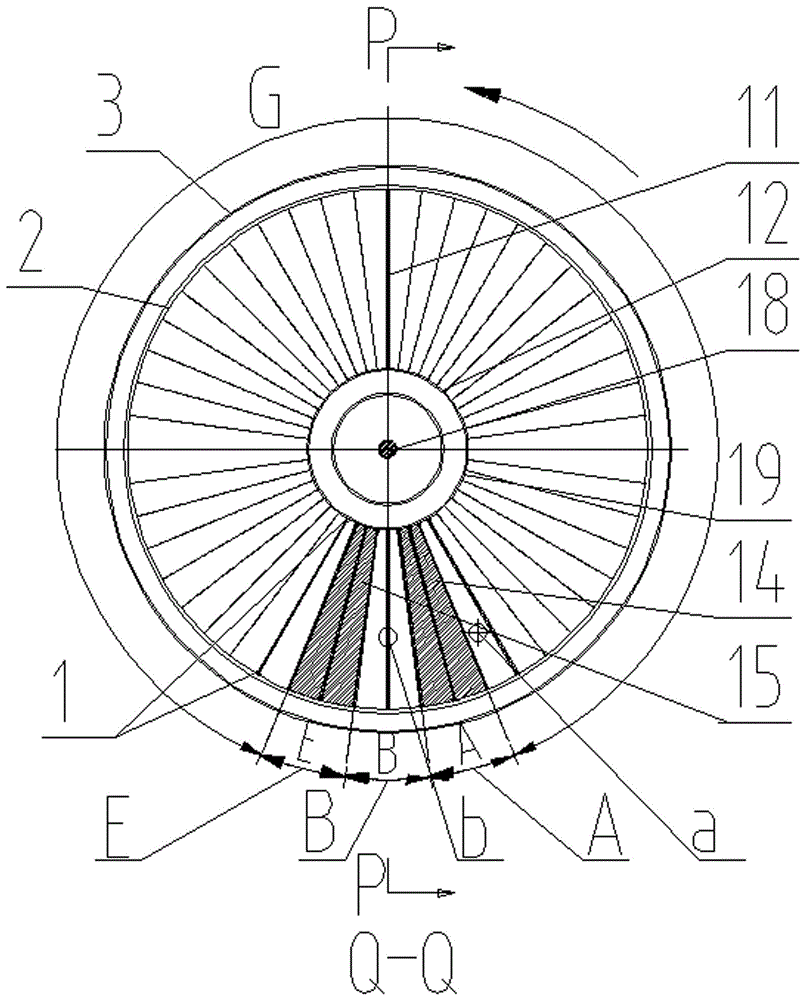

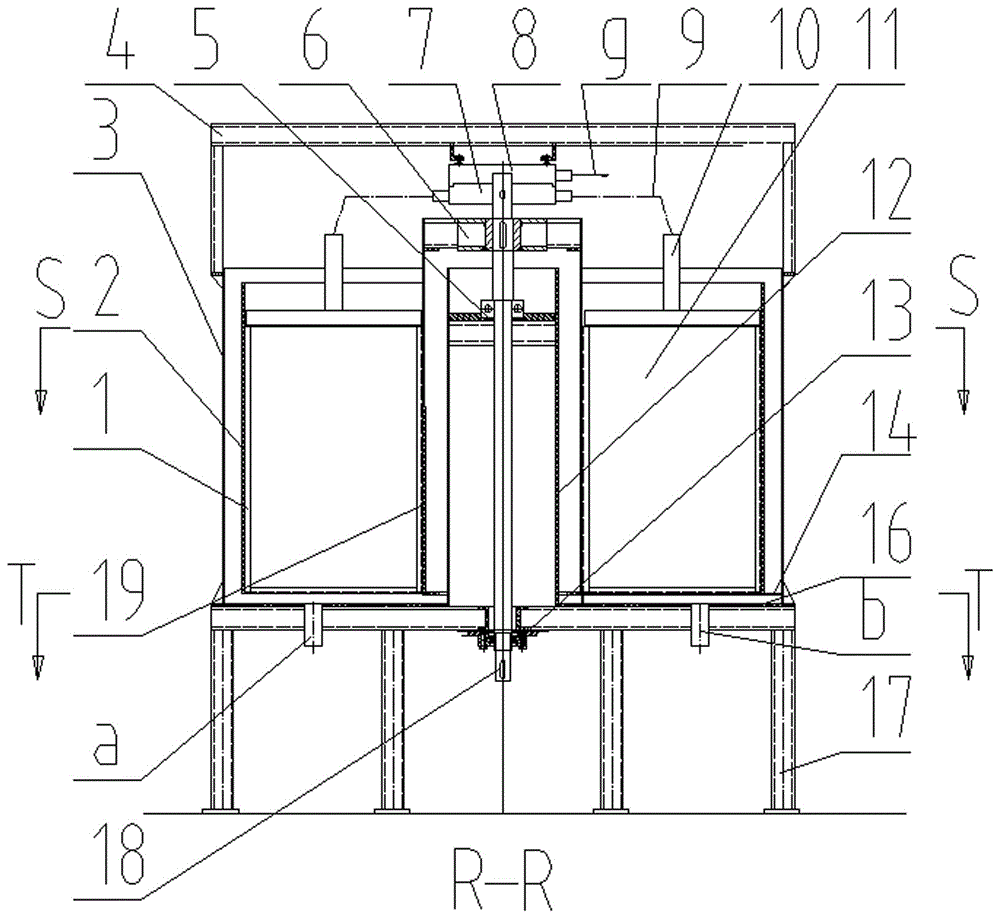

[0057] According to above-mentioned principle, the specific embodiment of the present invention is as follows:

[0058] figure 1 Shown is a structural representation of one of the present invention, figure 2 shown, is figure 1 Schematic diagram of the section along the Q-Q line, that is, the technical solution for discharging the concentrated suspension. From figure 1 and figure 2 It can be seen from figure 1 yes figure 2 Schematic diagram of the structure taken along the P-P section, a bottom plate 16 is fixed on the top of the support 17, an outer cylinder 3 is fixed on the bottom plate 16, and an inner cylinder 12 is fixed in the middle. The inner cylinder 12 connects with the support through the upper bearing 5 and the lower bearing 13 Seat 17 constitutes a rotational connection. The upper end of the transmission shaft 18 is fixedly connected with the distribution valve disc 7 of the filtrate distribution valve; the distribution valve static disc 8 is located abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com