Low-noise draught fan special for automatic vehicle washing machine and assembly method of draught fan

A car washing machine, low-noise technology, applied in the direction of machines/engines, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problems of abnormal working noise, self-weight, short service life, etc. The effect of weight, reduction of destructive force, and reduction of operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

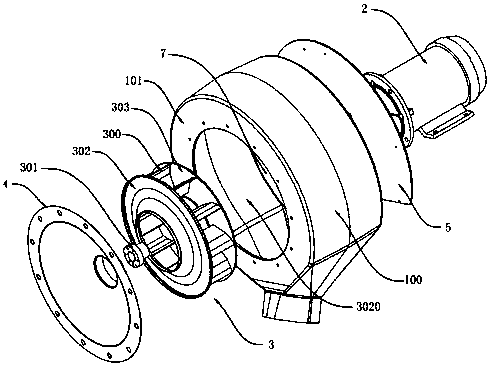

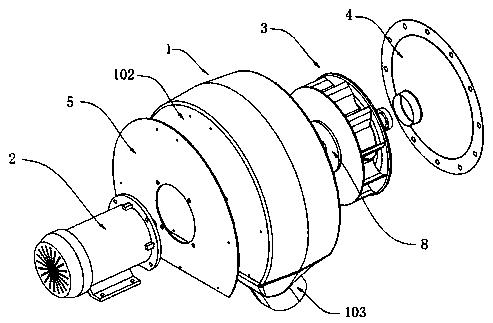

[0034] As shown in the figure, this embodiment provides a special low-noise fan for automatic car washing machines, which includes a fan cover 1, a motor 2 installed on the back of the fan cover 1, and a fan impeller 3 installed in the inner cavity of the fan cover 1;

[0035] The fan cover 1 includes a circumferential ring plate 100, an air inlet end ring plate 101 arranged on the front of the circumferential ring plate 100, an installation back plate 102 arranged on the back of the circumferential ring plate 100, and a ring plate arranged around the circumferential ring plate 100. Side exhaust pipe 103;

[0036] The motor 2 is fixedly installed on the outer end of the installation backplane 102, and the output shaft extends through the installation backplane 102 into the inner cavity of the fan cover 1;

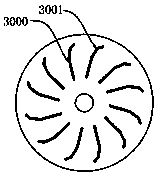

[0037]The fan impeller 3 includes a number of blades 300, a connecting sleeve 301, and an oppositely arranged air inlet end impeller disk 302 and an inner end impeller disk...

Embodiment 2

[0044] In order to further improve the anti-shock and shock-absorbing ability of the fan impeller, the diameter of the inner ring of the connecting sleeve 301 in this embodiment gradually increases from the inner end to the outer end, and a vulcanized rubber layer 6 is cast on the inner ring surface of the connecting sleeve 301. The thickness of the vulcanized rubber layer 6 gradually increases from the inner end to the outer end so that the diameter of the inner ring of the vulcanized rubber layer 6 is equal to the outer diameter of the output shaft. On the one hand, this design makes the inner ring surface of the connecting sleeve 301 closely fit the output shaft, and on the other hand On the one hand, when the fan impeller 3 swings, the fan impeller 3 drives the connecting sleeve 301 to swing, and the vulcanized rubber layer 6 gradually thickens from the inner end to the outside, which will significantly absorb vibration energy and slow down the vibration phenomenon.

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com