Detection apparatus positioning method

A detection device and positioning method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that affect the detection effect and the detection equipment cannot be aligned with the workpiece, so as to improve the detection effect and the alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

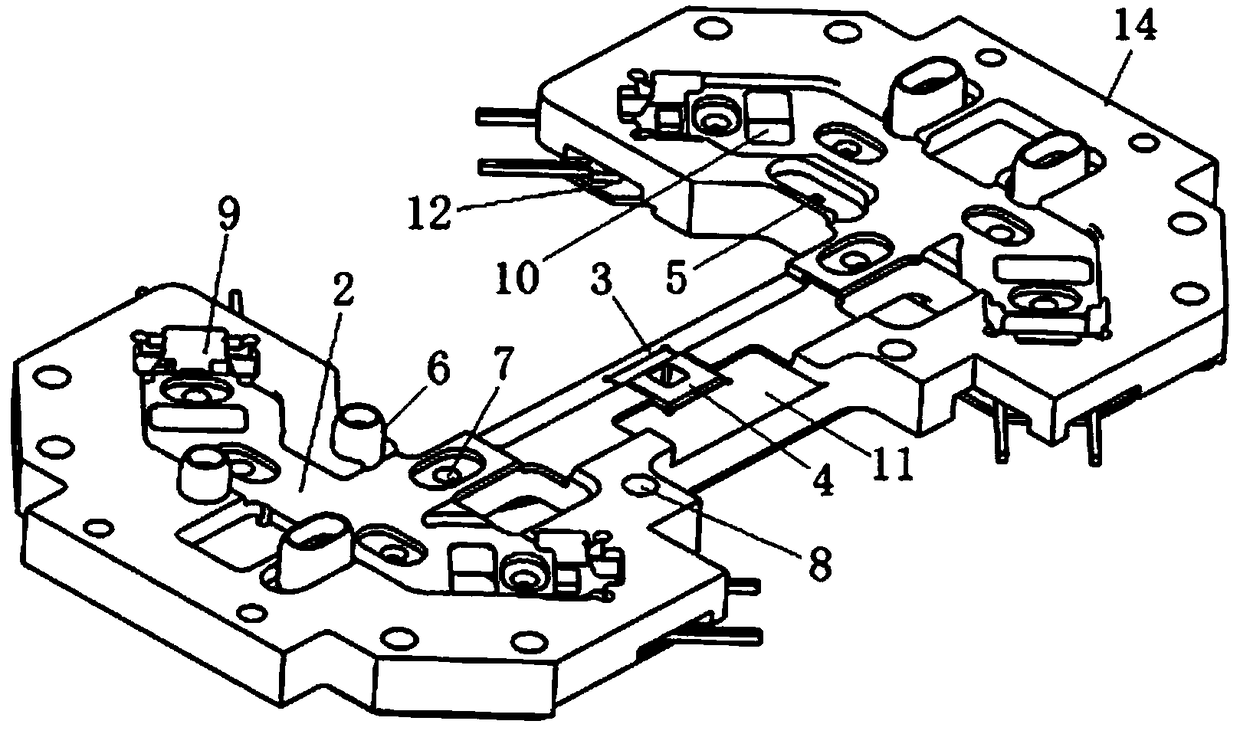

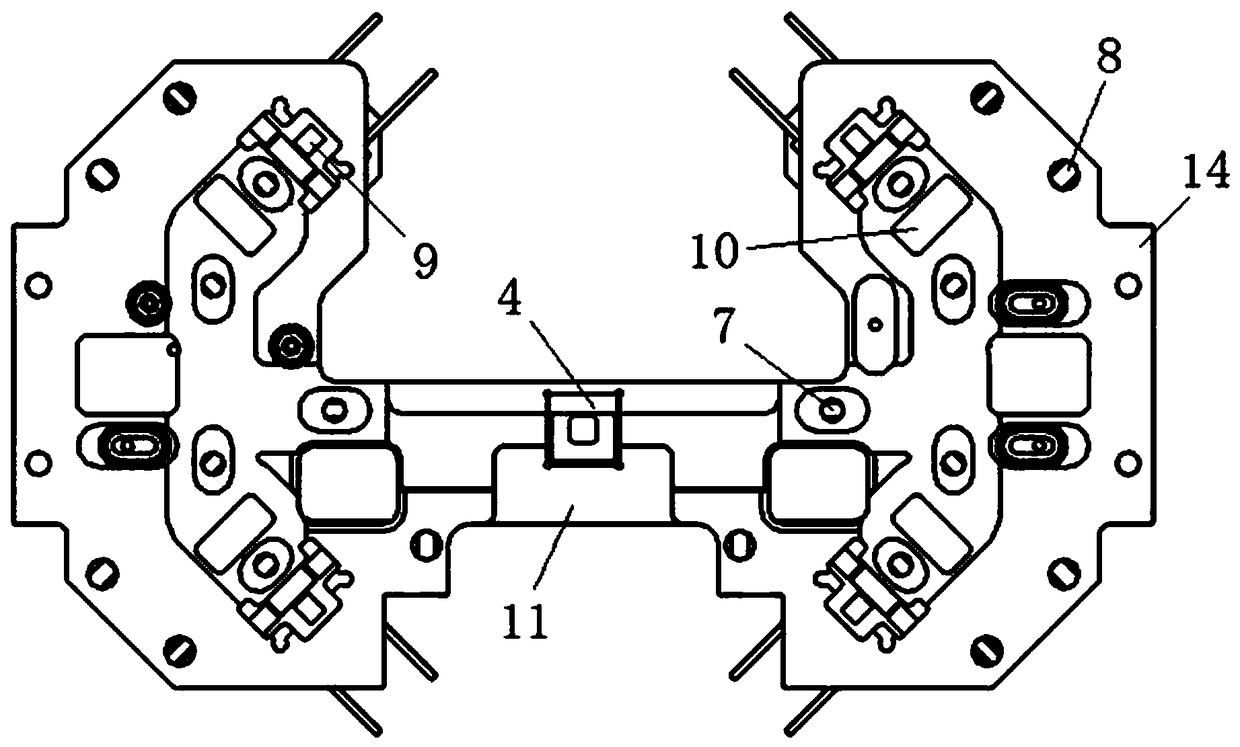

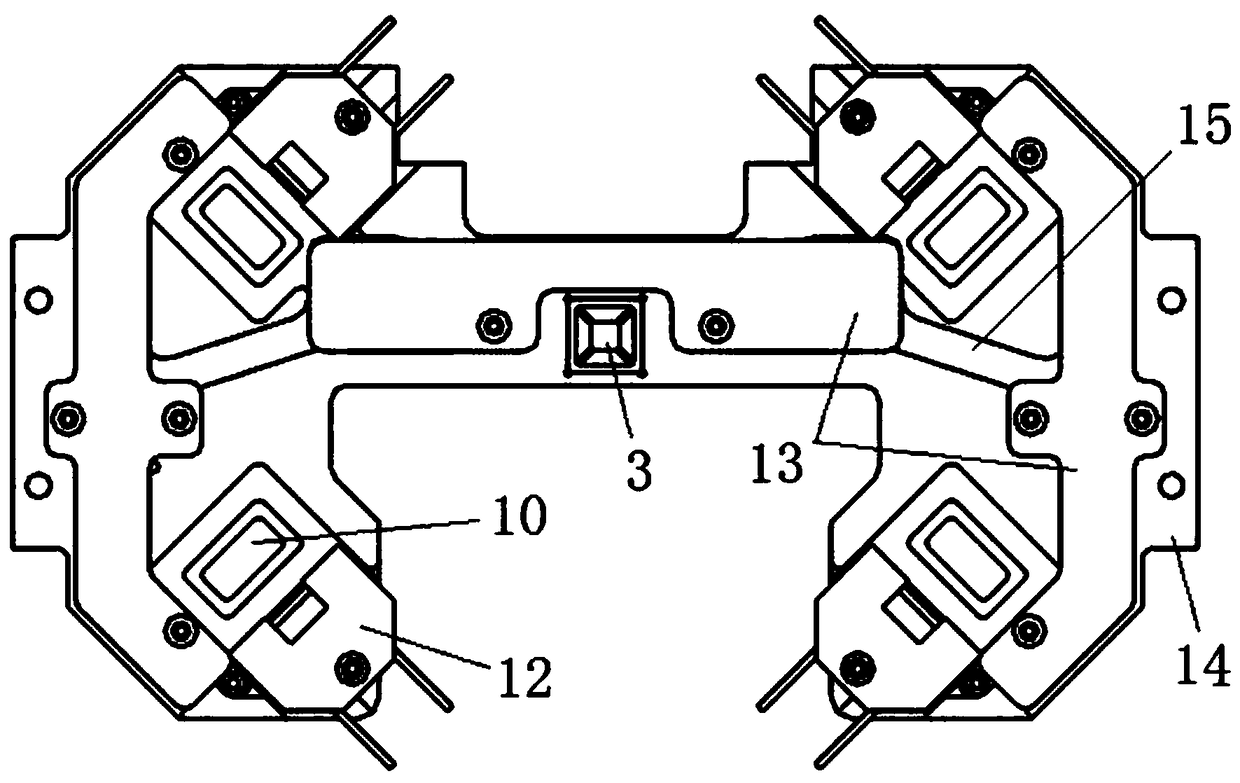

[0067] This embodiment provides a support jig 1, which is used to support the beam plate under the beam plate for fixed connection when the beam plate at the bottom of the notebook computer touch panel is detected, such as Figure 1~4 As shown, the support fixture 1 includes a workpiece accommodating groove 2, an avoidance detection hole 3, an avoidance hole fixture 4, a positioning column connection groove 5, a workpiece positioning column 6, a vacuum inlet 7, a vacuum outlet 8, and a backlight Through hole 9, avoidance positioning hole 10, fixture sliding groove 11, LED light source 12, light source line fixing plate 13, and fixed connection boss 14.

[0068] The workpiece accommodating groove 2 is located on the front of the supporting jig 1 , the workpiece accommodating groove 2 matches the shape of the detected workpiece, and the back of the workpiece can be placed flat in the workpiece accommodating groove 2 .

[0069] The position avoidance detection hole 3 is a through...

Embodiment 2

[0099] This embodiment provides a positioning carriage 16, which is used to connect and move the supporting jig 1, and cooperates with the supporting jig 1 to jointly fix the workpiece to be detected, so as to prevent the workpiece from shifting when the positioning carriage 16 moves, such as Figure 5-9 As shown, the positioning carriage 16 includes: a sliding main board 17 , a main sliding fixture 18 and a side sliding fixture 19 .

[0100] The sliding main board 17 has a groove for accommodating the supporting jig 1, and bolt holes for fixed connection with the supporting jig 1 are provided on both sides of the groove, and the supporting jig 1 can be fixed on the sliding main board after the bolt passes through the bolt hole. 17 in the groove; the bottom position on both sides of the sliding main board 17 is provided with a connection hole for connecting with the first sliding table module 30, after the sliding table block of the first sliding table module 30 is fixed on the...

Embodiment 3

[0117] This embodiment provides a detection station, which is used to set the workpiece on it, and then move the workpiece to the detection position, so that the workpiece can be detected on the detection workbench, such as Figure 10-13 As shown, the detection station includes: a positioning carriage 16 , a fixed table 28 , a hydraulic drive rod 29 , and a first slide module 30 .

[0118] The first slide module 30 that is used to connect the positioning carriage 16 is provided on the fixed table surface 28, and the positioning carriage 16 can slide on the first slide module 30, so that the objects fixed on the positioning carriage 16 The workpiece moves to the detection position; the positioning carriage 16 has two groups juxtaposed on the fixed table surface 28, and the positioning carriage 16 of the two groups has a separate driving device to drive. When testing, one group of positioning carriages 16 The workpiece detection can be carried out on it, and the other set of pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com