Detection method for performance of ceramic combination agent abrasive tool

A vitrified bond and detection method technology, which is applied in the field of abrasives and abrasive tools, can solve the problem that the holding force cannot be directly measured, and achieve the effect of easy operation and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a. Assemble the mold and put in 15 grams of Al 2 o 3 -Na 2 O-B 2 o 3 -SiO 2 Basic vitrified bond, compacted with a press plate.

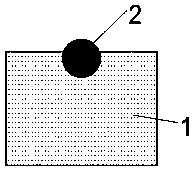

[0026] b. Take the center line of a single corundum abrasive grain with a radius of 1 mm as the center line to mark a horizontal line, and draw two upper and lower marks at a distance of 2 / 3 mm from the horizontal line.

[0027] c. Insert the lower end of the above-marked corundum ball abrasive grains into the middle of the vitrified bond block in step a, and press the upper end mark of the abrasive grains into the bond block completely.

[0028] d. Carry out belt mold curing for the mold assembled above, that is, raise the temperature from room temperature to 250°C at a heating rate of 5°C / min and keep it warm for 1 hour, then raise the temperature to 250°C at a heating rate of 4.5°C / min and keep it warm for 2 Hours, the temperature was raised to 720°C at a heating rate of 5.5°C / min and kept for 2.5 hours, and then cooled to room tempe...

Embodiment 2

[0032] a. Assemble the mold and put in 15 grams of Al 2 o 3 -Na 2 O-B 2 o 3 -SiO 2 Basic vitrified bond, compacted with a press plate.

[0033] b. Take the center line of a single corundum abrasive grain with a radius of 2 mm as the center line to mark a horizontal line, and draw two marks at a distance of 4 / 3 mm from the horizontal line.

[0034] c. Insert the lower end of the above-marked corundum ball abrasive grains into the middle of the vitrified bond block in step a, and press the upper end mark of the abrasive grains into the bond block completely.

[0035] d. Carry out belt mold curing for the mold assembled above, that is, raise the temperature from room temperature to 250°C at a heating rate of 5°C / min and keep it warm for 1 hour, then raise the temperature to 250°C at a heating rate of 4.5°C / min and keep it warm for 2 Hours, the temperature was raised to 720°C at a heating rate of 5.5°C / min and kept for 2.5 hours, and then cooled to room temperature to obtain...

Embodiment 3

[0039] a. Assemble the mold and put in 15 grams of Al 2 o 3 -Na 2 O-B 2 o 3 -SiO 2 Basic vitrified bond, compacted with a press plate.

[0040] b. Take the center line of a single corundum ball abrasive grain with a radius of 3 mm as the center line to mark a horizontal line, and draw two upper and lower marks at a distance of 2 mm from the horizontal line.

[0041] c. Insert the lower end of the above-marked corundum ball abrasive grains into the middle of the vitrified bond block in step a, and press the upper end mark of the abrasive grains into the bond block completely.

[0042] d. Carry out belt mold curing for the mold assembled above, that is, raise the temperature from room temperature to 250°C at a heating rate of 5°C / min and keep it warm for 1 hour, then raise the temperature to 250°C at a heating rate of 4.5°C / min and keep it warm for 2 Hours, the temperature was raised to 720°C at a heating rate of 5.5°C / min and kept for 2.5 hours, and then cooled to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com