A parameter optimization method for pull rod for installing aircraft airborne equipment

A technology of airborne equipment and optimization methods, applied in the direction of design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve problems such as inability to guarantee, and achieve the effect of wide application range and accurate optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

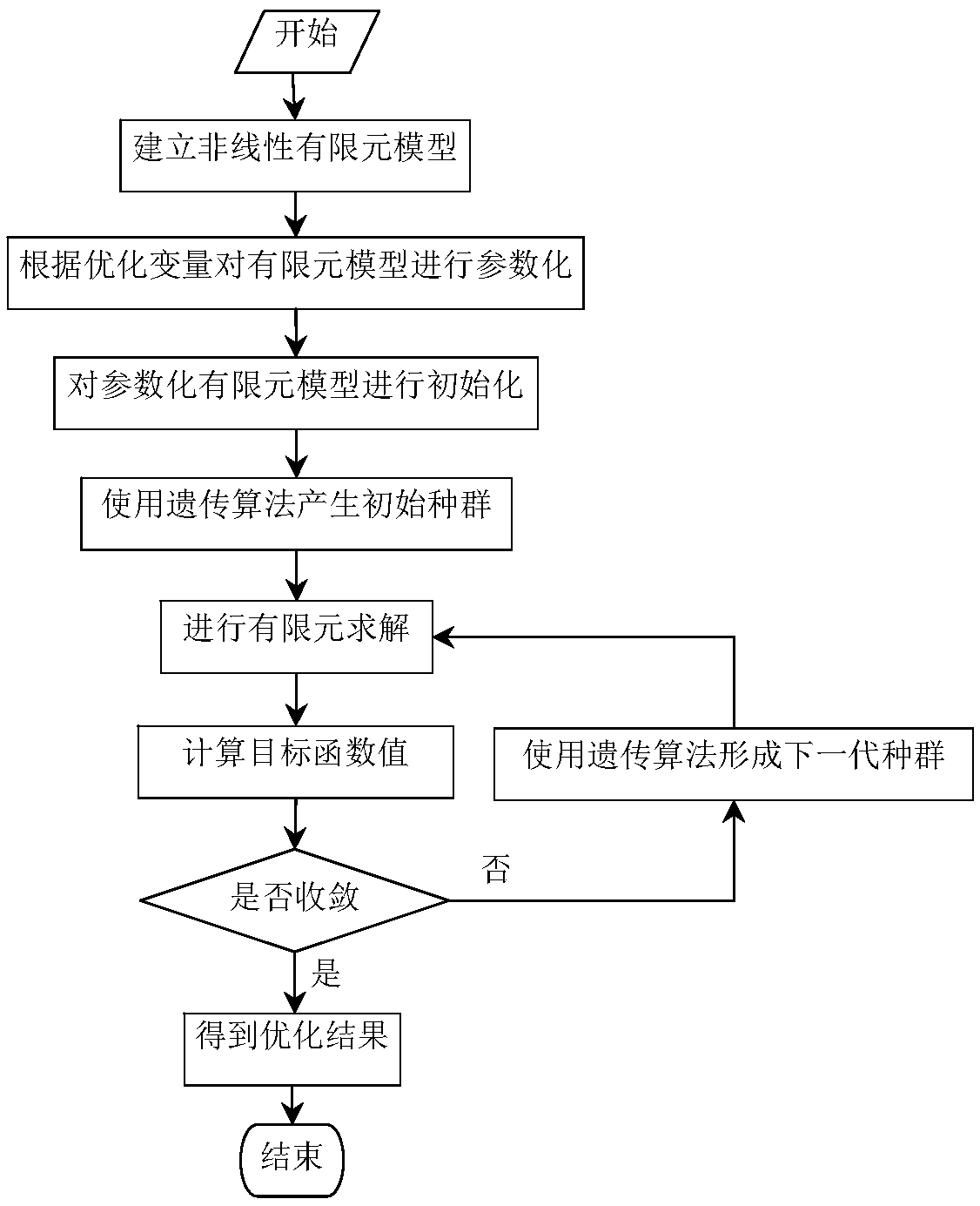

[0025] See attached picture, figure 1 is a schematic block diagram of the tie rod parameter optimization method proposed in this application.

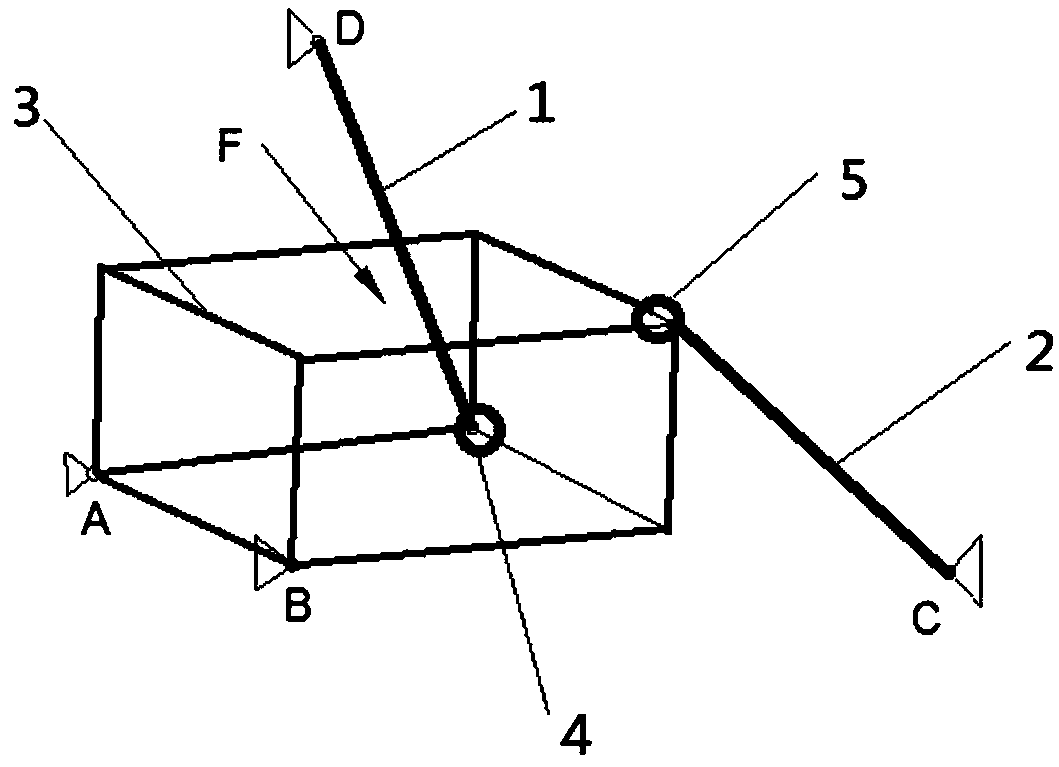

[0026] An airborne device 3 is installed on the aircraft body through the first tie rod 1 and the second tie rod 2, and the present invention will be further described in detail by optimizing the cross-sectional area of the first tie rod 1 and the second tie rod 2 as an example.

[0027] Such as figure 2 As shown, the airborne equipment 3 is installed on the airframe structure. Points A, B, C, and D in the figure are the installation intersections between the airborne equipment 3 and the airframe, and they are all hinge supports. It is fixed with the body, at the installation intersection point D, connects the airborne equipment 3 through the first tie rod 1 and the first shock absorber 4, and at the installation intersection point C, connects the airborne equipment through the second tie rod 2 and the second shock absorber 5 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com