An equalization circuit for parallel charging and bi-directional flyback type double discharge equalization and a control method thereof

A bidirectional flyback and balancing circuit technology, applied in charge balancing circuits, battery circuit devices, circuit devices, etc., can solve problems such as inconsistent battery energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

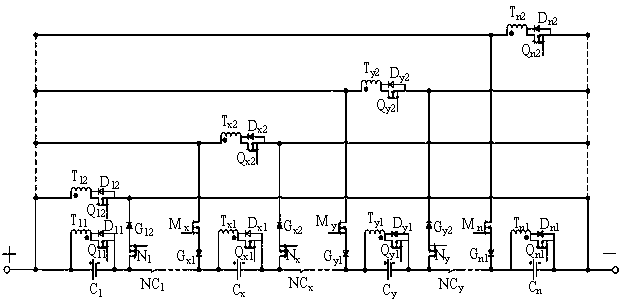

[0032] Embodiment 1: as figure 1 As shown, an equalization circuit of parallel charging and bidirectional flyback double discharge equalization consists of a battery pack, a relay NC j , bidirectional flyback transformer, Mosfet switch M a , Mosfet switch N b , High reverse voltage Schottky diode G a1 , High reverse voltage Schottky diode G b2 constitute;

[0033] The battery pack consists of n single cells C i Composition, a normally closed relay NC is connected in series between every two adjacent single cells j , the bidirectional flyback transformer consists of a transformer primary winding T i1 , Transformer secondary winding T i2 , Mosfet switch Q i1 , Mosfet switch Q i2 , high reverse voltage Schottky diode D i1 , High reverse voltage Schottky diode D i2 constitute;

[0034] The transformer primary winding T e1 One end of the single battery C e The positive pole of the transformer primary coil T e1 The other end of the Mosfet switch Q e1 Drain, high reve...

Embodiment 2

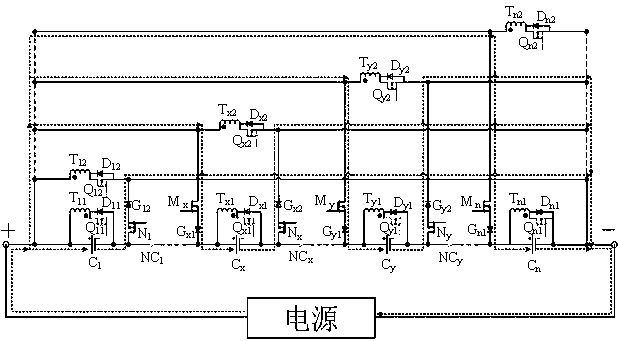

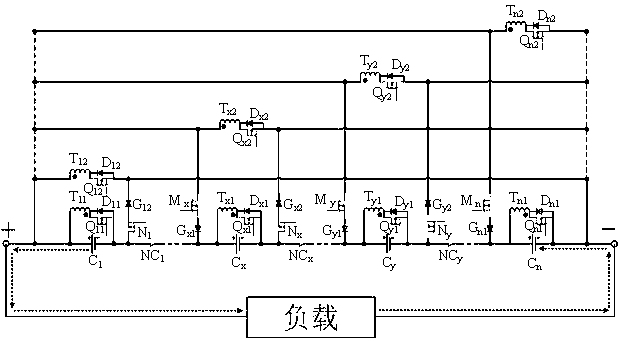

[0051] Embodiment 2: Take 4 single cells as an example.

[0052] During charging (such as Figure 4 , 5 ), using PWM to control the Mosfet switch to only turn on M a (a=2,3,4), N b (b=1,2,3), control normally closed relay NC j (j=1,2,3,...n-1) Turn it on so that it is in the off state. At this time, all the cells are directly connected in parallel to the power supply, assuming that the order in which the cells reach the charging cut-off voltage is C 3 、C 2 、C 1 、C 4 .

[0053] (1) Control and single battery C 3 Corresponding Mosfet switch M 3 , N 3 disconnected, thereby placing the cell C 3 Isolate the charging circuit.

[0054] (2) Control and single battery C 2 Corresponding Mosfet switch M 2 , N 2 disconnected, thereby placing the cell C 2 Isolate the charging circuit.

[0055] (3) Control and single battery C 1 Corresponding Mosfet switch N 1 disconnected, thereby placing the cell C 3 Isolate the charging circuit.

[0056] (4) Control and single batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com