A simple photoreflective synergistic device for a fixed plate photovoltaic module array power generation system

A technology for photovoltaic modules and power generation systems, applied in photovoltaic power generation, support structures of photovoltaic modules, photovoltaic modules, etc., can solve problems such as practical application of utility models, inability to be directly practical, and complex basic structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

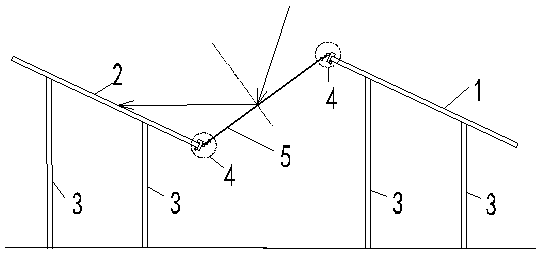

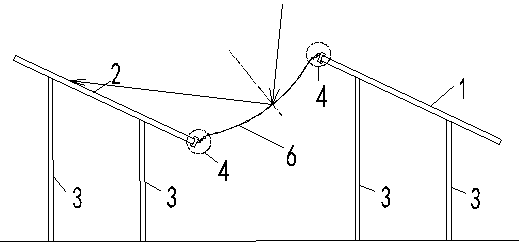

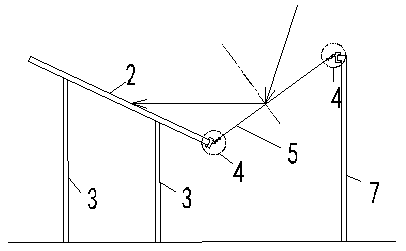

[0023] Select a fixed flat-panel photovoltaic module array power generation system installed on a flat roof, which is composed of 2 rows and 3 columns, a total of 6 polysilicon photovoltaic modules connected in series. The size of the photovoltaic module is 1.64m×0.99m, it is inclined towards the south, and the angle between the inclination and the ground plane is 25 degrees, and the horizontal distance between the rows of photovoltaic modules is 1.06m. The white aluminum-plastic panel is used as the reflector. The width of the reflector is the same as that of the photovoltaic module, and the length is 1.2m, which satisfies figure 1 The overlapping conditions between the two rows of photovoltaic modules shown and the front and back. Each pair of photovoltaic modules in the front and rear rows is equipped with a reflector; the first row of photovoltaic modules in the front is equipped with a reflector bracket, such as image 3 As shown, each photovoltaic module is equipped wi...

Embodiment 2

[0026] Select a fixed flat-panel photovoltaic module array power generation system installed on a flat roof, which is composed of 2 rows and 3 columns, a total of 6 polysilicon photovoltaic modules connected in series. The size of the photovoltaic module is 1.64m×0.99m, it is inclined towards the south, and the angle between the inclination and the ground plane is 25 degrees, and the horizontal distance between the rows of photovoltaic modules is 1.06m. The white aluminum-plastic panel is used as the reflector. The width of the reflector is the same as that of the photovoltaic module, and the length is 1.2m, which satisfies figure 1 The overlapping conditions between the two rows of photovoltaic modules shown and the front and back. Each pair of photovoltaic modules in the front and rear rows is equipped with a reflector; the first row of photovoltaic modules in the front is equipped with a reflector bracket, such as image 3 As shown, each photovoltaic module is equipped wi...

Embodiment 3

[0029] Select a fixed flat-panel photovoltaic module array power generation system installed on a flat roof, which is composed of 2 rows and 3 columns, a total of 6 polysilicon photovoltaic modules connected in series. The size of the photovoltaic module is 1.64m×0.99m, it is inclined towards the south, and the angle between the inclination and the ground plane is 25 degrees, and the horizontal distance between the rows of photovoltaic modules is 1.06m. White polystyrene foam boards are used as reflectors. The width of the reflector is the same as that of the photovoltaic module, and the length is 1.2m, which satisfies figure 1 The overlapping conditions between the two rows of photovoltaic modules shown and the front and back. Each pair of photovoltaic modules in the front and rear rows is equipped with a reflector; the first row of photovoltaic modules in the front is equipped with a reflector bracket, such as image 3 As shown, each photovoltaic module is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com