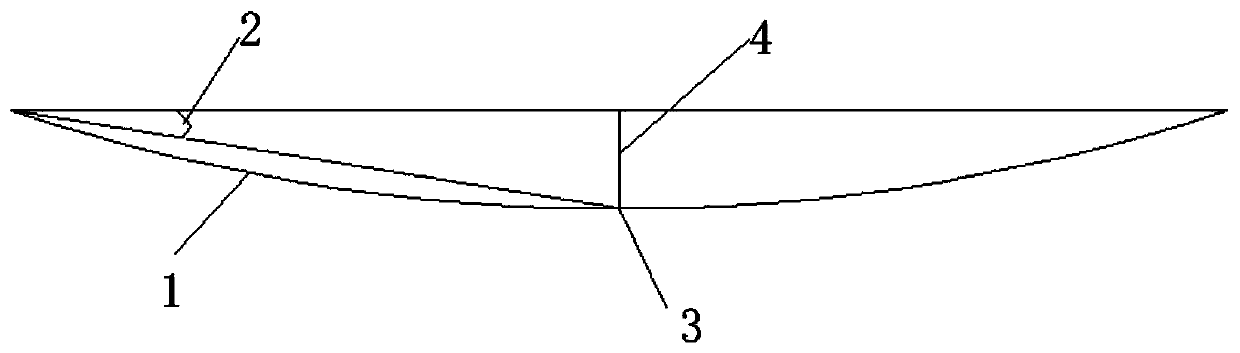

Novel concave component

A component and a new type of technology, applied in electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of increasing power generation, increasing the amount of light incident on the surface of the cell, and achieve the effect of increasing the output of power generation and increasing the amount of incident.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] A new type of recessed photovoltaic module, the structure of which is a front panel of light-transmitting toughened glass, packaging materials, solar cells, back panel glass, junction box and aluminum frame.

[0029] The combined steps of this technical solution are as follows:

[0030] 1. The front transparent tempered glass adopts embossed and coated tempered glass, the size is 1968*986mm, the thickness is 2mm, and the surface stress after tempering is above 40Mpa;

[0031] 2. The packaging material adopts 0.57mm POE and adopts 1+1 stacking method;

[0032] 3. The cell uses high-efficiency cells, the size is 156*156mm, each string is 12 cells, a total of 6 strings, the cell spacing is 3mm, and the string spacing is 4mm;

[0033] 4. Translucent tempered glass on the back plate adopts embossed and coated tempered glass, the size is 1968*986mm, the thickness is 2mm, and the surface stress after tempering is above 40Mpa;

[0034] 5. Wiring adopts split junction box;

[0035] 6. Insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com