Solar Modules Containing Thermally Sealed Composite Layers

A solar module and composite layer technology, which is applied in semiconductor devices, photovoltaic power generation, electrical components, etc., can solve the problem of limiting the applicability of solar modules and other electronic components, and can not specifically reduce the working temperature of solar modules and increase the volume and thickness of solar modules Size and other issues, to achieve the effect of improving photoelectric conversion efficiency and power generation output, improving photoelectric conversion efficiency and power generation output, and slowing down high-temperature aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] "Preparation Example 1: Thermal Conductive Resin Paste"

[0053] First, prepare ethylene methacrylate resin (ethylene methacrylic acid resin, EMA) and aluminum oxide, the melting index (melting index, MI) of the ethylene methacrylate resin at 190 ° C is 8, and the thermal conductivity is 0.29W / mK; and the average particle size of aluminum oxide is 5 microns.

[0054] Next, with the mixing ratio shown in Table 1, the ethylene methacrylate resin and aluminum oxide were mixed with each other by twin-screw kneading and extruding equipment, so as to obtain thermal conductive resin slurries of experimental groups 1 to 4. The thermal conductivity of the thermally conductive resin paste of each experimental group is tested by a thermal conductivity meter (test specification: ASTM E1461), and the results are shown in Table 1 below.

[0055] Table 1: Mixing ratios of aluminum oxide and ethylene methacrylate resins (unit: volume percent (vol%)) in experimental groups 1 to 4 and t...

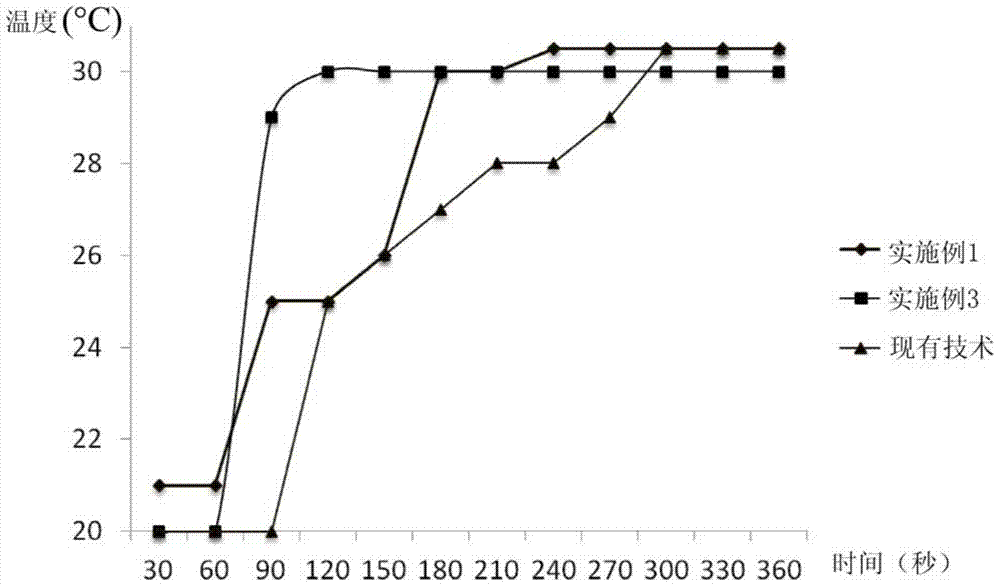

Embodiment 1 to 3

[0060] "Examples 1 to 3: Thermally Conductive Sealing Composite Layer"

[0061] In Examples 1 to 3, the thermally conductive resin slurries prepared in the experimental groups 2 to 4 of the aforementioned Preparation Example 1 were respectively selected to make the thermally conductive resin layer of the thermally conductive sealing composite layer. The detailed manufacturing method of the thermally conductive sealing composite layer is as follows:

[0062] The above-mentioned thermally conductive resin slurry is made into a thermally conductive resin layer with an area of 15 cm*15 cm and a thickness of 200 microns by blown film method; then polyethylene-methacrylic acid glycidol is coated on the thermally conductive resin layer by hot-melt processing ester, and made into an adhesive resin layer with a thickness of 20 microns, that is, the preparation of the thermally conductive sealing composite layer is completed.

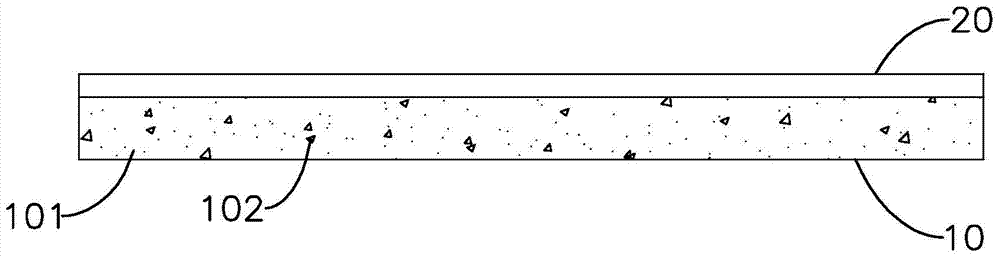

[0063] see figure 1 As shown, the thermally conductive ...

Embodiment 4 to 6

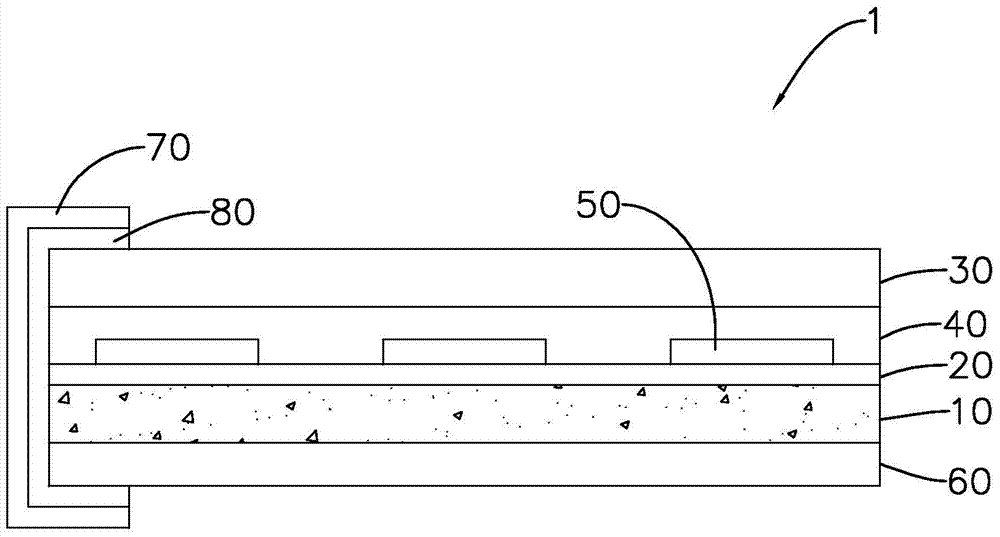

[0074] "Examples 4 to 6: Solar Modules Containing Thermally Conductive Sealing Composite Layers"

[0075] The solar modules of Examples 4 to 6 respectively include the heat-conducting sealing composite layers of Examples 1 to 3, and the solar modules are generally produced by the following manufacturing methods:

[0076] First, stack the transparent glass substrate, ethylene vinyl acetate copolymer resin layer, 72 single crystal solar cell wafers (sold by Motech), a thermally conductive sealing composite layer with a total thickness of 220 microns, and a polyester plastic backsheet; The ethylene-vinyl acetate copolymer resin layer is laminated at 140° C., so that the ethylene-vinyl acetate copolymer resin undergoes a cross-linking curing reaction (thermal setting) until its cross-linking density reaches more than 85%, so as to obtain a laminated structure.

[0077] Next, pour the silica gel slurry containing aluminum oxide into the aluminum frame to obtain an aluminum frame co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com