Plant underground harvester

A harvester and plant technology, applied in excavator harvesters, harvesters, excavators, etc., can solve the problems of difficult adaptation, unclean picking, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

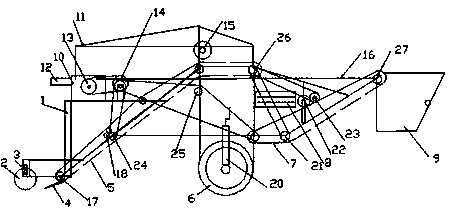

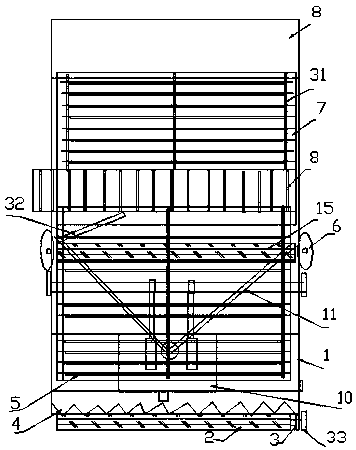

[0019] Examples, combined with figure 1 -2, embodiment 1, a plant underground harvester, including frame 1, ground wheel 6, gearbox 10, blade 4 and two circulating chain screens 5, 7, the ground wheel 6 is two, install In the middle of the frame 1; the gearbox 10 is installed at the front end of the frame 1, and the connector 12 is set in front of the gearbox 10 to connect with the tractor. The first circulating chain screen 5 is set under the gearbox 10, and the second circulating chain screen 7 is set After the first circulating chain sieve 5, a small part overlaps each other, and the blade 4 is arranged before the first circulating chain sieve 5; the operation of the chain sieve 5, 7 is connected to the chain sieve by the gears of the belt pulley 13, 14 of the gearbox 10 Shaft-end gears 17, 21, 24, 26, 27 are characterized in that a separate impurity-removing chain sieve 8 is arranged in the middle of the overlapping part of the chain sieve, and the impurity-removing chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com