Compound material grating sandwich flange forming mold and forming method

A composite material and forming mold technology, applied in the field of flange manufacturing, can solve the problems of low manufacturing efficiency, high labor cost, and few literature studies on the manufacturing process, and achieve the effect of improving manufacturing efficiency and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment, the present invention is described in detail:

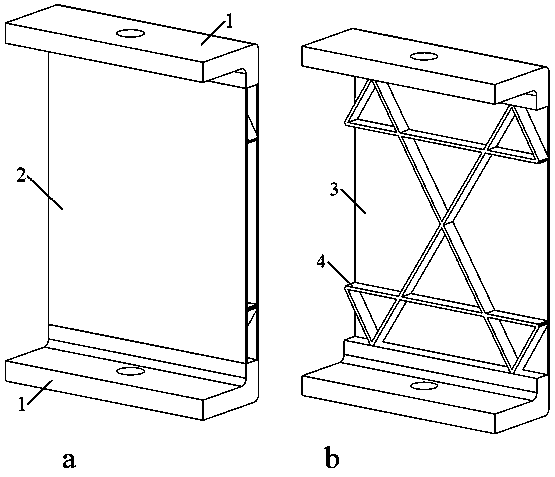

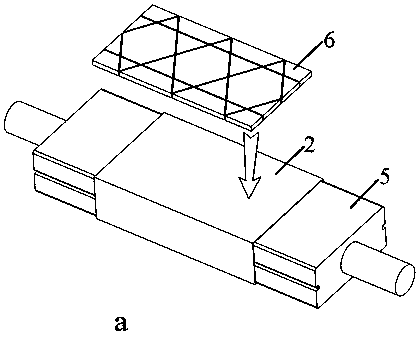

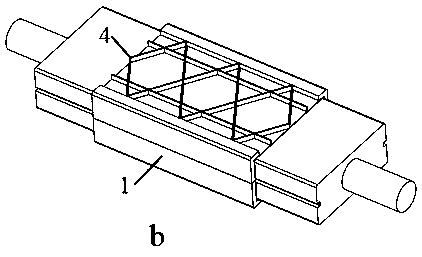

[0013] A composite material grille sandwich flange forming mold, comprising: a rotating shaft, a silicone rubber block, a plastic foam block and a pressing plate; Outside the plastic foam block. During the winding forming process of the composite grille sandwich flange structure, each part of the forming mold is used in sequence: first, the inner skin of the forming structure is wound through the rotating shaft; then the silicone rubber blocks are pasted on the upper and lower surfaces of the rotating shaft, and the gap between the rubber blocks is used as the winding path. Form the grille; remove the silicone rubber block, use the plastic foam block to fill the groove formed by the grille, use the plastic foam block and the grille as the winding support surface, and wrap the outer skin; After the structure is solidified and formed, the pressing plate is remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com