Ultralarge-diameter spiral corrugated pipe alignment device and method for applying same

A spiral corrugated pipe and ultra-large-diameter technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of low butt joint accuracy of super-large-diameter spiral corrugated pipes, inability to move within a small range, and high construction safety risks, so as to achieve convenient and accurate docking, Avoid long operation time and solve the effect of poor docking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

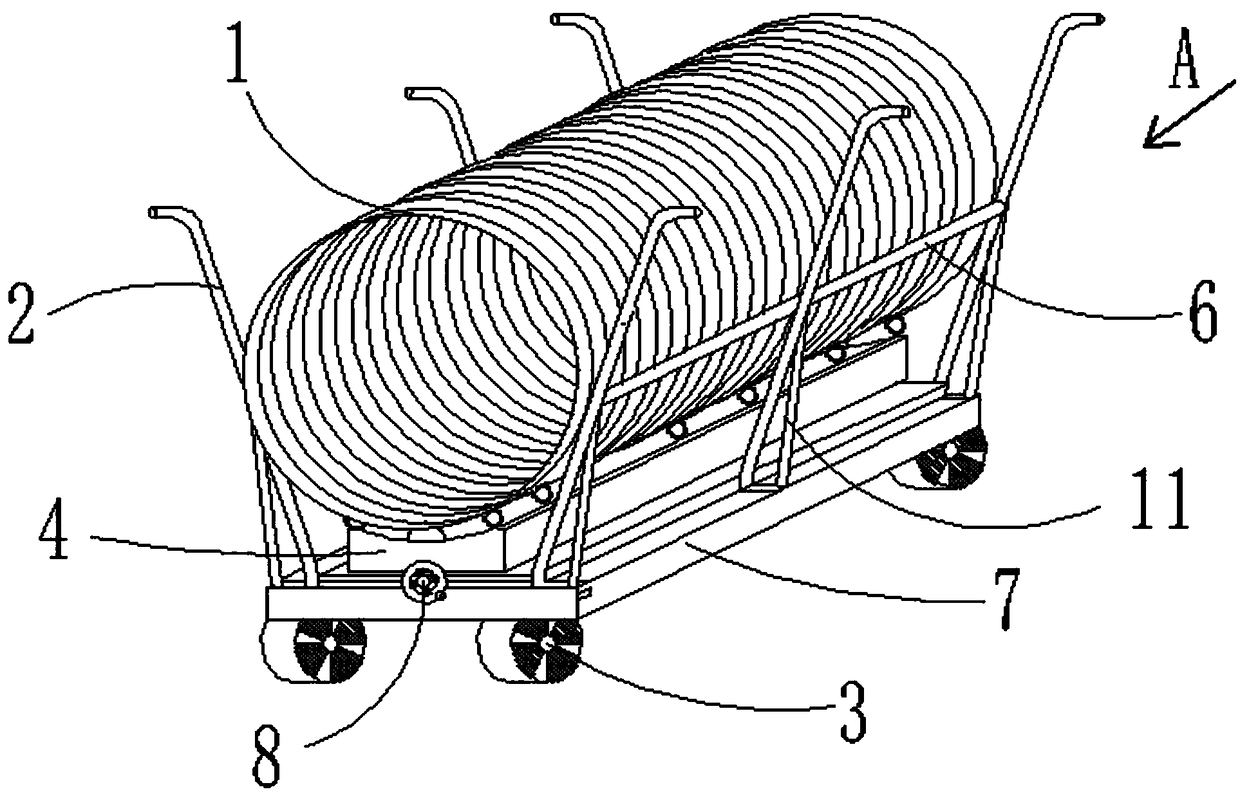

[0038] like Figure 1-6 As shown, the super-large-diameter spiral corrugated pipe mating device proposed by the present invention is characterized in that it includes a support rod 2 , a lifting device 5 , a fixing plate 7 and a wheel 3 .

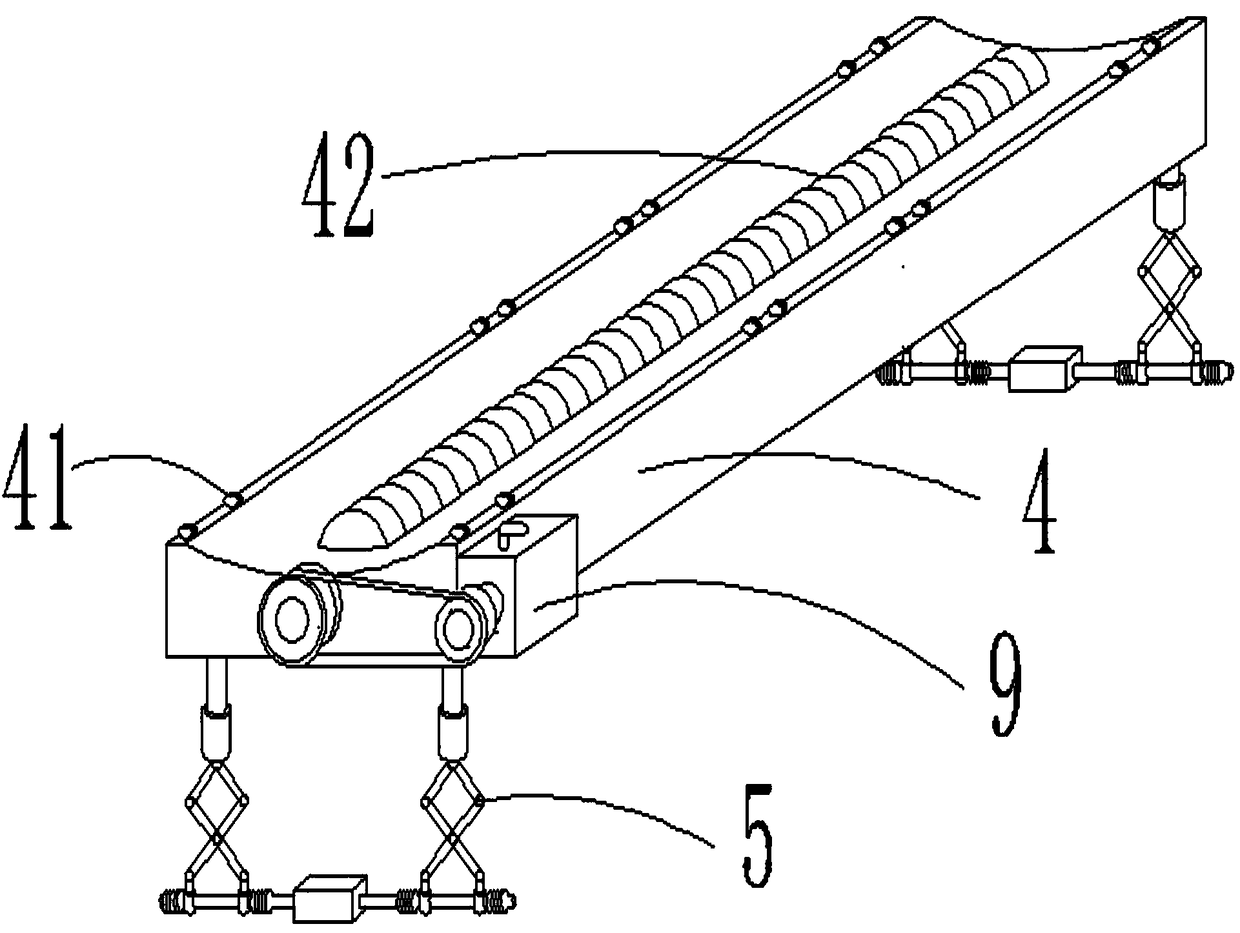

[0039]The lifting device 5 is provided with two groups, which are respectively located at the front and rear ends of the bottom surface of the square groove 72; each group of lifting devices 5 includes a hinge connecting rod 51, a hydraulic cylinder 52 and a connecting column 53, and the hinge connecting rod 51 and the connecting column 53 are equipped with two. The bottoms of each group of two hinge links 51 are welded with a sliding sleeve 10, and the left and right sides of the sliding sleeve 10 are respectively fixedly connected with a hydraulic telescopic sleeve 55 and a fixed sleeve 54, and the sliding sleeve 10 and the fixed sleeve 54 run through the same connection. Rod, the sliding sleeve 10 can slide freely in the connecting rod....

Embodiment 2

[0044] The present invention also discloses a method for using the super-large-caliber spiral corrugated pipe counterpart device, which is characterized in that it includes the following steps:

[0045] Step 1. Hoist the spiral corrugated pipe counterpart device to the bottom of the foundation pit by a crane;

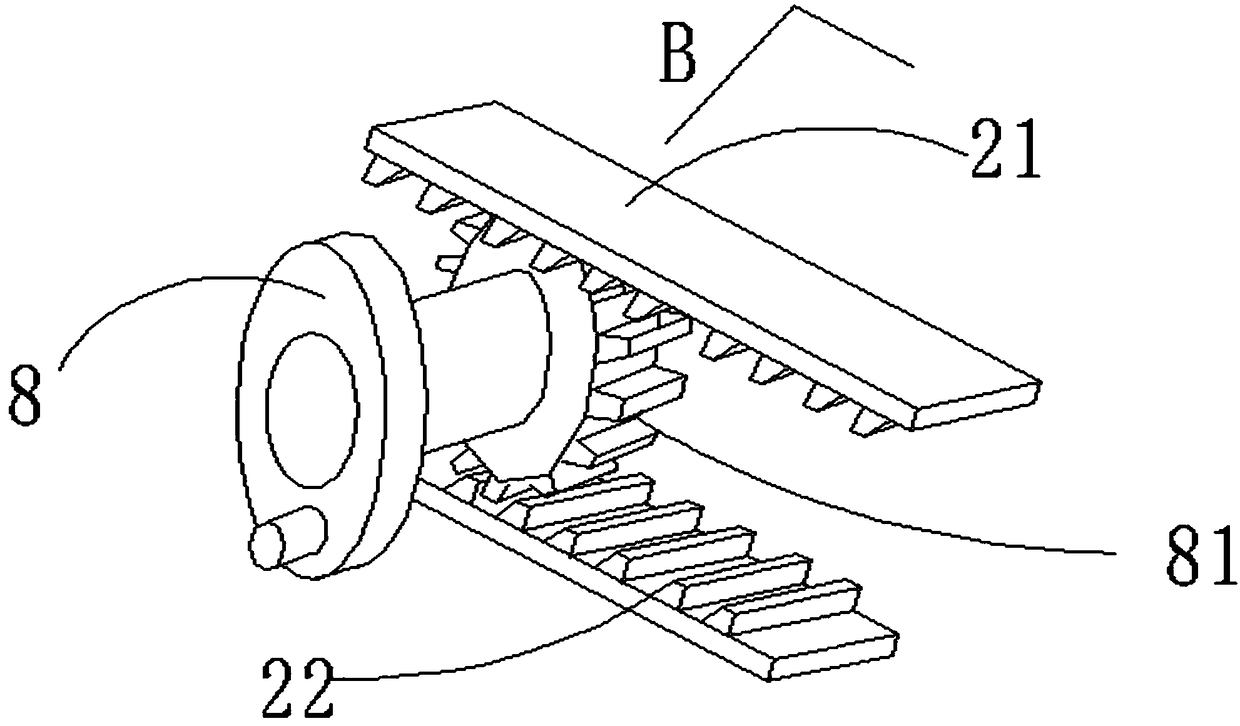

[0046] Step 2. According to the diameter of the spiral bellows 1, look up the table to find the scale corresponding to the hand wheel 8 and the height of the universal wheel 41, and then adjust the adjustment bolts of the hand wheel 8 and the universal wheel 41 so that the transmission rod 42 and the universal wheel 41 It is in the same circle as the spiral bellows 1; then the spiral bellows 1 is hoisted between the support rods 2 by a crane;

[0047] Step 3. Push the spiral corrugated pipe mating device to move to a distance of 50-100 mm from the mating port of the spiral corrugated pipe 1 that has been installed;

[0048] Step 4. Shake the hand wheel to move the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com