Benzoic acid purification method and purification equipment

A purification method, benzoic acid technology, applied in the separation/purification of carboxylic acid compounds, chemical industry, climate sustainability, etc., can solve the problems of easy agglomeration, difficult centrifugation, high flash point of benzoic acid, etc., and achieve production cost Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0017] Benzoic acid purification method is characterized in that:

[0018] (1) The benzoic acid solution obtained by oxidation of toluene has a mass content of 51% benzoic acid. The benzoic acid solution crystallizes and hangs on the wall in a tube at 110-120 °C, and the crystals on the inner wall of the tube melt at 130-140 °C and is purified to obtain The mass content of benzoic acid solution is 95.2%;

[0019] (2) Repeat the operation of step (1) for the benzoic acid solution obtained by melting and recycling, and the mass content of benzoic acid in the finally obtained benzoic acid solution is 99.8%.

specific Embodiment 2

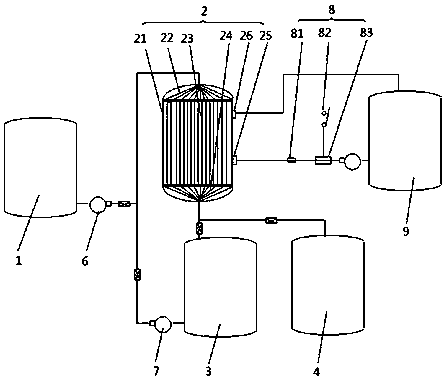

[0020] Please refer to the attached figure 1 Shown, be used to realize the benzoic acid purification device of described benzoic acid purification method, it is characterized in that, comprise toluene oxidation liquid storage tank 1, crystallization tubular heat exchanger 2, semi-finished product tank 3, finished product tank 4, toluene oxidation liquid The discharge port of storage tank 1 is connected to the feed port of crystallization tubular heat exchanger 2 through the feeding pump 6, and the discharge port of crystallization tubular heat exchanger 2 is connected to semi-finished tank 3, finished product tank 4, and toluene oxidation liquid storage tank 1 are connected separately, valves are respectively provided on the pipelines connecting the outlet of the crystallization tubular heat exchanger 2 with the semi-finished tank 3, the finished product tank 4, and the toluene oxidation liquid storage tank 1, and the semi-finished tank 3 is connected to the crystallization tub...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap