A Control Method for Improving the Plasticity of 95crmo Hollow Steel

A control method and plasticity technology, applied in the control field of improving the plasticity of 95CrMo hollow steel, can solve the problems of high notch sensitivity and low plasticity of hollow steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

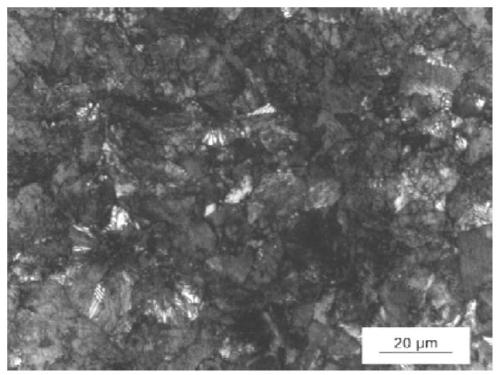

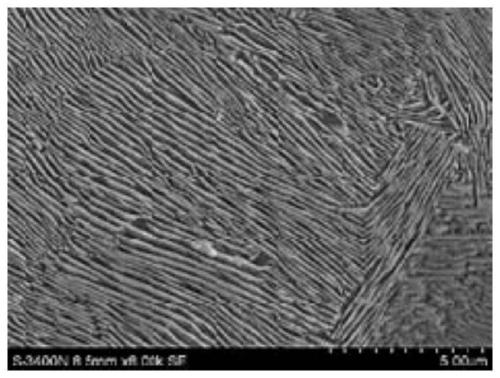

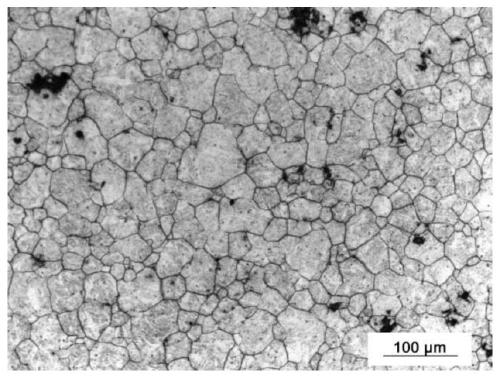

[0022] The center of the square billet produced by electric furnace smelting, LF refining and continuous casting is drilled and then filled with core materials, and then rolled into hexagonal hollow steel bars through steps such as heating in a heating furnace, rolling, and controlled cooling. 1) Rolling: The rolling start temperature is 1025°C, the rough rolling is rolled in six passes in a tandem mill, and the inlet temperature of the tandem rolling mill is 950°C. Before entering the finishing mill, the surface of the billet is bright without obvious black spots. The finish rolling temperature is 845°C to obtain fine pearlite cluster size. 2) Controlled cooling: After finishing rolling and before the upper cooling bed, water cooling-recovery five-stage control is adopted, the cooling rate is 20°C / s, the network carbide is reduced, and the spacing of pearlite sheets is refined, and the temperature of the upper cooling bed is 750°C. The upper cooling bed is covered with a hea...

Embodiment 2

[0024] The center hole of the square billet produced by electric furnace smelting, LF refining and continuous casting is drilled and then filled with core material, and then rolled into hexagonal hollow steel rods through steps such as heating in a heating furnace, rolling, and controlled cooling. 1) Rolling: The rolling start temperature is 1005°C, the rough rolling is rolled in six passes in a tandem mill, and the inlet temperature of the tandem rolling mill is 935°C. Before entering the finishing mill, the surface of the billet is bright without obvious black spots. The entrance temperature of finish rolling is 835°C to obtain a fine pearlite cluster size. After finish rolling to before the upper cooling bed, water cooling-recovery five-stage control is adopted, and the cooling rate is 10°C / s to reduce network carbides and refine the spacing of pearlite sheets , The upper cooling bed temperature is 720°C. The upper cooling bed is covered with a heat preservation cover, and...

Embodiment 3

[0026] The center hole of the square billet produced by electric furnace smelting, LF refining and continuous casting is drilled and then filled with core material, and then rolled into hexagonal hollow steel rods through steps such as heating in a heating furnace, rolling, and controlled cooling. 1) Rolling: The rolling start temperature is 1045°C, the rough rolling is rolled in six passes in a tandem mill, and the entrance temperature of the tandem rolling mill is 965°C. Before entering the finishing mill, the surface of the billet is bright without obvious black spots. The finish rolling entrance temperature is 855°C to obtain fine pearlite cluster size. 2) Controlled cooling: after finishing rolling and before the upper cooling bed, water cooling-recovery five-stage control is adopted, the cooling rate is 25°C / s, the network carbide is reduced, and the spacing of pearlite sheets is refined, and the temperature of the upper cooling bed is 780°C. The upper cooling bed is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com