Multifunctional basin-type support and a method for installing and measuring force and adjusting height

A multi-functional, bearing technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems of inability to determine the force change of the bearing, complicated height adjustment methods and procedures, hidden dangers of structural safety, etc. Reliable, achieve manual detection or automatic detection, and the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

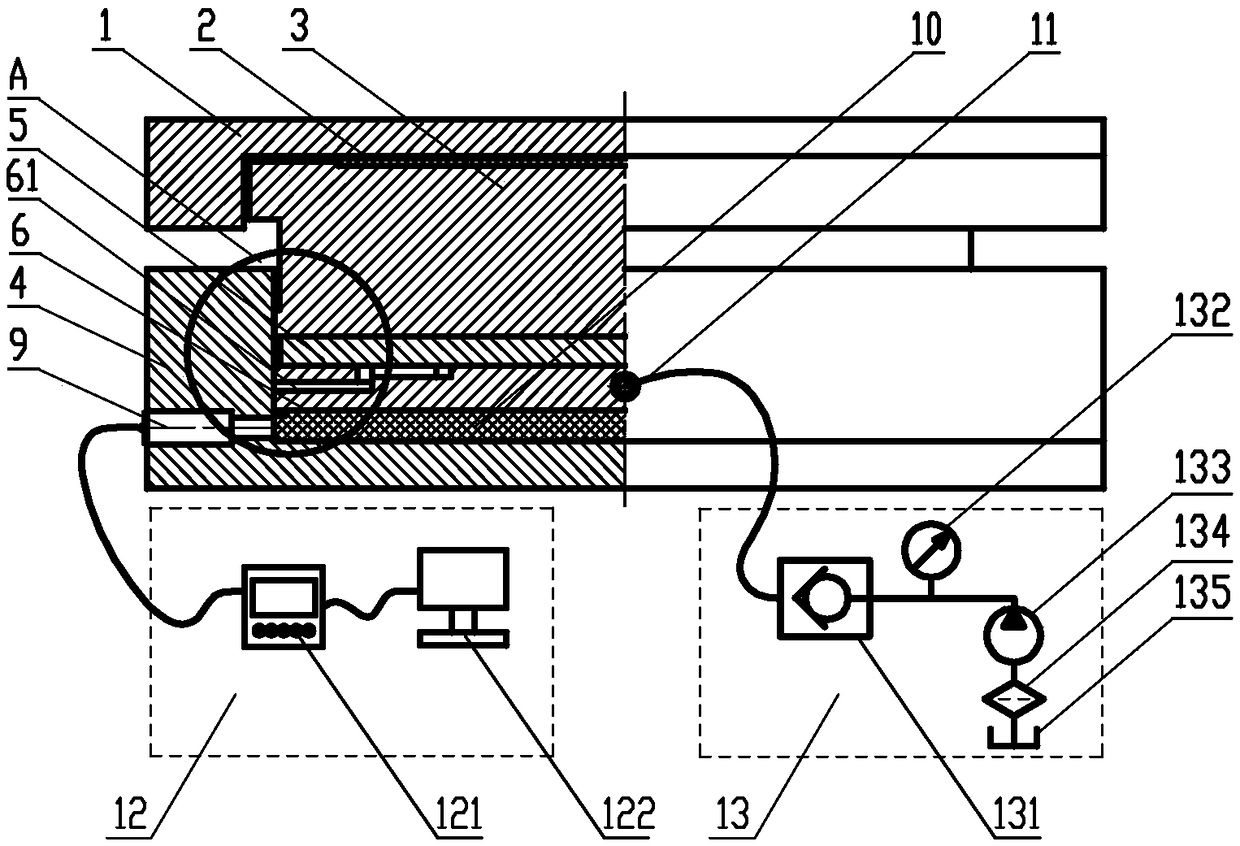

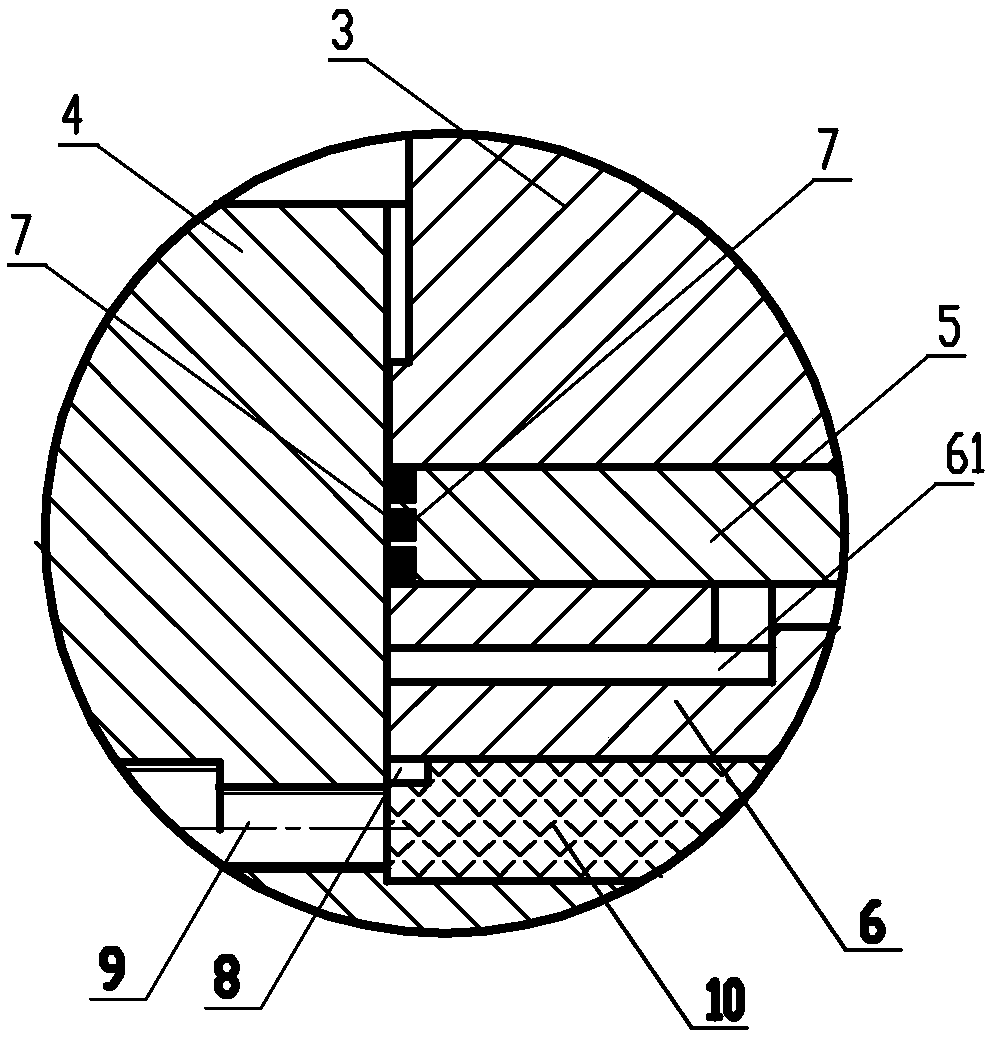

[0066] A multifunctional basin-type support, including a support body, the support body includes a support top plate 1 and a support bottom plate 4, and a steel lining plate 3 is installed between the support top plate 1 and the pelvic cavity of the support bottom plate; its features In that: it also includes height adjustment system and force measurement system;

[0067] The height adjustment system includes an adjustment sealing plate 5 installed in the support body, a filling backing plate 6 and a high-pressure filling device 13 installed outside the support body, and the adjusting sealing plate 5 and filling backing plate 6 are successively installed on the In the pelvic cavity on the bottom surface of the steel liner 3, the filler plate 6 fits in a small gap with the inner wall of the pelvic cavity of the base plate, and the outer edge of the adjustment sealing plate 5 matched with the inner wall of the pelvic cavity is provided with an annular groove inlaid with a sealing...

Embodiment 2

[0075] A multi-functional pot-type support and a method for installing and measuring force height adjustment, the method is the installation method of a multi-functional pot-type support described in Embodiment 1 and the method for using it to measure force height adjustment , including the following steps:

[0076] S1. Install the multifunctional basin support

[0077] S11. Install the support body: install the multifunctional basin-type support body on the pier pad;

[0078] S12. Zero adjustment of the force-measuring element: zero-adjust the fiber grating force-measuring element installed outside the pelvic cavity of the base plate;

[0079] S13. erecting or pouring the upper beam body;

[0080] S2. Force measurement

[0081] S21. installing a detection device;

[0082] Connect the external detection device to the support body: connect the demodulator of the detection device to the fiber grating force measuring element installed outside the pelvis of the support floor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com