Forced-cooling drain flash tank and utilization method thereof

A technology of hydrophobic expansion and forced cooling, which is applied in the direction of boiler cleaning equipment, etc., can solve the problems of reducing the efficiency of heat energy recovery and utilization, and achieve the effects of reducing emissions, reducing visual pollution, and reducing emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

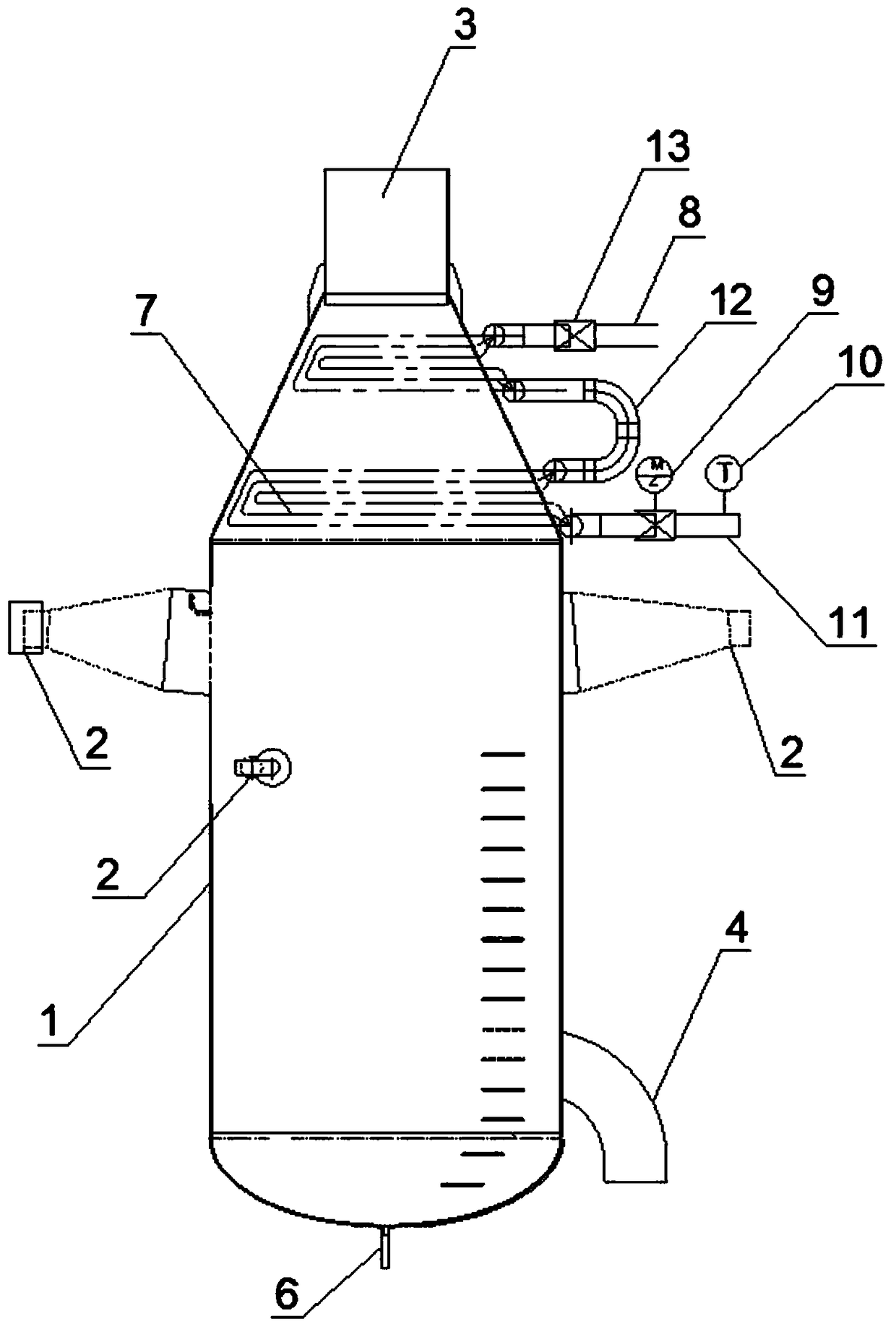

[0026] Such as figure 1 As shown, the forced cooling hydrophobic expander includes an expander body 1 with a conical upper part and a cylindrical lower part. The top of the expander body 1 is provided with a steam outlet 3, the upper part is provided with a hydrophobic inlet 2, and the lower part is provided with a The drain outlet 4 is provided with a sewage outlet 6 at the bottom. In order to meet the requirements of different sizes of drains, the drain inlet 2 includes a plurality of drains of different sizes. As in this embodiment, 3 drains of different sizes are configured, and can Choose the appropriate size of the drain port according to the size of the drain flow.

[0027] The top of the expander body 1 is provided with a cooling heat exchange tube bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com