Air-drying device for cleaned accumulator plates

An air-drying device and post-cleaning technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of excessive water vapor, cracking, and difficult discharge, and achieve the effect of high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

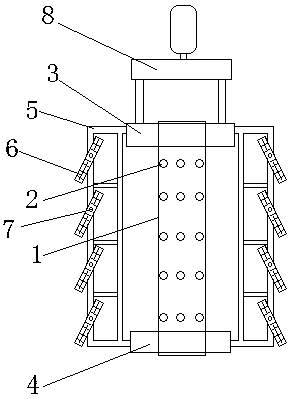

[0016] Such as figure 1 As shown, a kind of air-drying device of the battery plate of the present invention after cleaning includes a vertical main air duct 1, the upper end of the main air duct 1 is closed, and the lower end of the main air duct 1 is externally connected to an external heating device. The heat is supplied by external heating equipment, and the main air duct 1 has its own air pump to blow air into the main air duct 1;

[0017] A plurality of exhaust outlets 2 are distributed on the main air duct 1, an upper swivel 3 is arranged at the upper end of the main air duct 1, and a lower swivel 4 is arranged at the lower end of the main air duct 1, and the upper swivel 3 and A pair of parallel grids 5 are arranged between the lower swivel rings 4, and a screen frame 6 for placing pole plates is installed between a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com