A method for ammonia extraction and reuse in LED-MOCVD process tail gas membrane and adsorption coupling

A process and tail gas technology, applied in separation methods, chemical instruments and methods, combined devices, etc., can solve the problems of inability to recover ammonia for reuse, inability to recover and reuse ammonia, etc., to achieve stable process, reduce exhaust emissions, and high yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

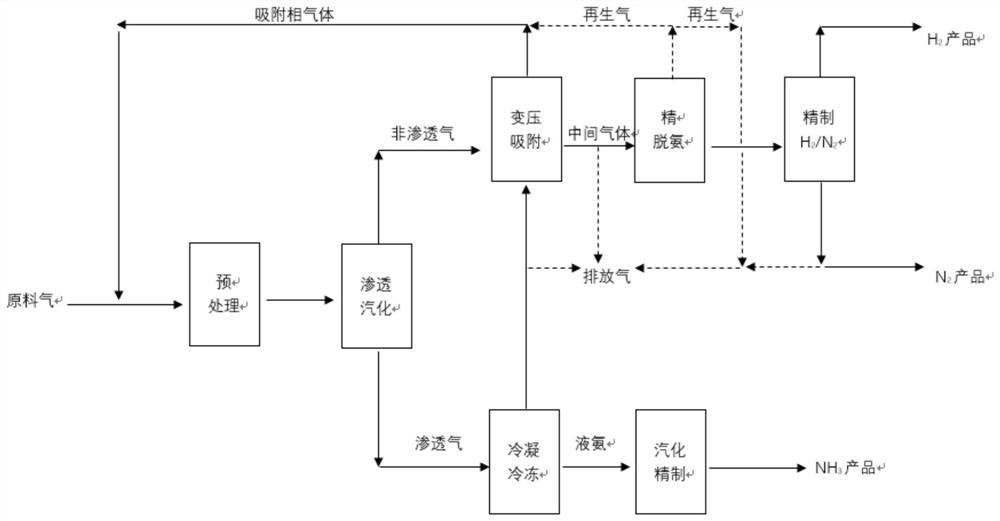

[0035] Such as figure 1 As shown, a LED-MOCVD process tail gas film and adsorption coupling method for ammonia extraction and reuse, the specific implementation steps include,

[0036] (1) Raw material gas, that is, the exhaust gas in the process of preparing light-emitting diode LEDs based on the growth of gallium nitride GaN epitaxial wafers by MOCVD metal oxide chemical vapor deposition at atmospheric pressure. Its main composition is nitrogen N2: 46% (v / v, below Similar), hydrogen H2: 34%, ammonia NH3: 19%, the remaining 1% is a small amount of metal ions, particles, arsine, methane CH4, water H2O, carbon monoxide CO, carbon dioxide CO2, oxygen O2 and other impurity components, Pressure is normal pressure, temperature is normal temperature;

[0037] (2) Pretreatment. The raw material gas is sent to the pretreatment unit composed of dust collector, particle filter and oil mist collector through the blower. Under the operating conditions of 0.2-0.3MPa pressure and normal te...

Embodiment 2

[0041] Such as figure 1 As shown, on the basis of Example 1, the raw material gas is pretreated and then pressurized to 1.2-1.4 MPa, the temperature remains unchanged, and enters the pervaporation membrane process. The ammonia concentration in the non-permeated gas produced is 5-8%. Enter the pressure swing adsorption process consisting of 6 towers, in which one adsorption tower is always in the adsorption state, and the other adsorption towers are in the desorption steps of forward discharge, reverse discharge, vacuuming, washing, forward pressure charging and final charging, etc., twice Pressure equalization; the ammonia concentration in the non-adsorbed phase gas flowing out from the pressure swing adsorption process is less than 0.5%, and it directly enters the temperature swing adsorption fine deamination process composed of two towers and the subsequent hydrogen / nitrogen extraction process. The ammonia concentration is 16-20%. After the raw material gas is pressurized to...

Embodiment 3

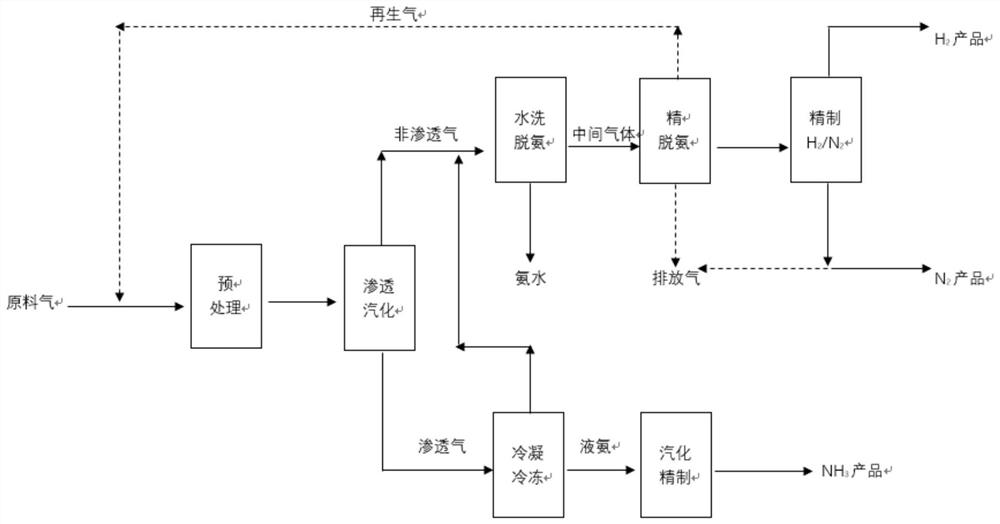

[0043] Such as figure 2 As shown, on the basis of Examples 1 and 2, the raw material gas is pretreated and then pressurized to 1.2-1.4 MPa, the temperature remains unchanged, and enters the pervaporation membrane process, and the ammonia concentration in the non-permeated gas produced is 5-8%. , directly enter the water washing ammonia removal process, the ammonia concentration in the non-permeable gas after deammonization by the water washing tower is less than 0.1-0.3%, and then enter the temperature swing adsorption fine deammoniation process composed of two towers and the subsequent hydrogen / nitrogen extraction process, Ammonia water with an ammonia concentration of 4-8% is formed at the bottom of the water washing tower, which is sent to the ammonia water concentration process to reach 20% to form an ammonia water by-product for output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com