A titanium alloy revolving body component and its shape correction method and forming method

A titanium alloy and revolving body technology is applied in the field of titanium alloy material forming to achieve the effect of high thermal expansion coefficient difference, small thermal expansion coefficient difference, and avoiding damage to components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

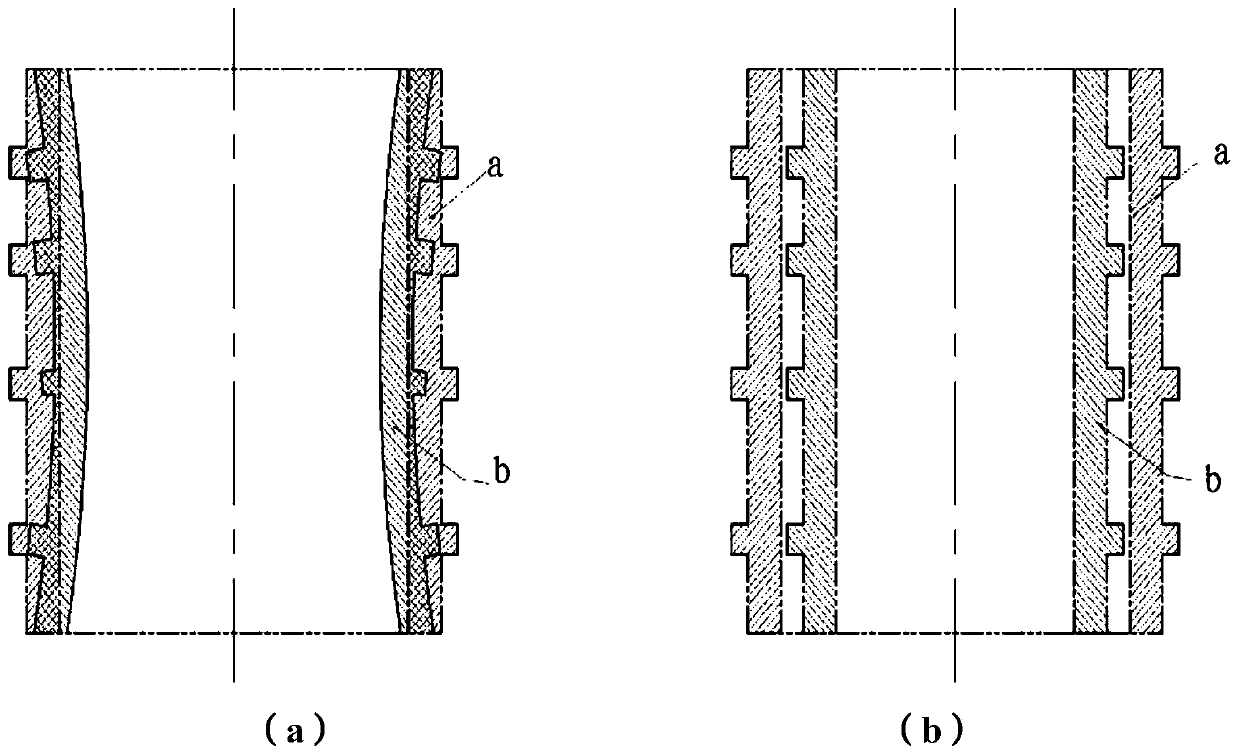

[0067] Such as figure 2 As shown in b, this embodiment provides a cylindrical titanium alloy member with a design inner hole size of 800 mm, a coaxiality requirement of 0.2, and a design wall thickness of 5 mm;

[0068] First prepare a titanium alloy component blank by a hot isostatic pressing process, the wall thickness of the blank is 10mm, and the value of m is 5‰, and the shape of the blank is corrected. The specific measures are as follows:

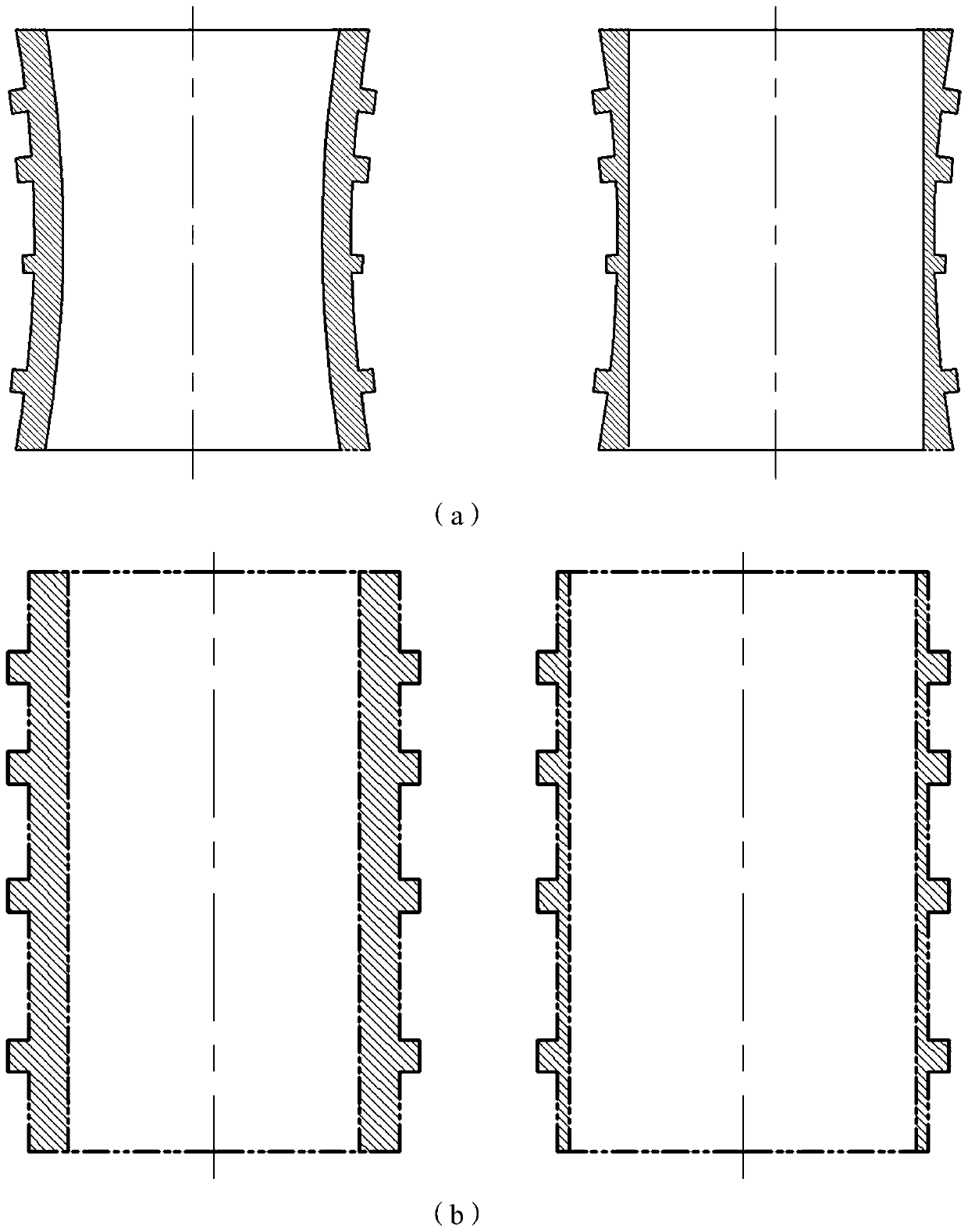

[0069] Before the shape correction, the inner wall of the blank is turned into a smooth cylindrical surface while the wall thickness is reserved for subsequent processing of 2mm, such as image 3 as shown in b. During the processing, the size and position deviation of the outer wall of the component is measured at any time, and the coaxiality between the inner wall and the outer wall of the product is controlled at less than 0.2 after processing.

[0070] 0Cr18Ni9 stainless steel is selected as the material of the calibration mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com