Intelligent detecting and sizing device for aeroengine spindle

An aero-engine and intelligent detection technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reducing the accuracy of workpieces, high labor intensity, and affecting performance, so as to eliminate errors caused by human participation, reduce labor intensity, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

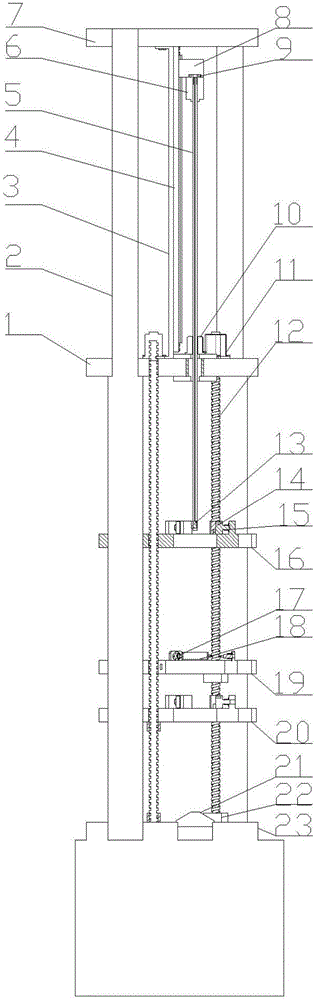

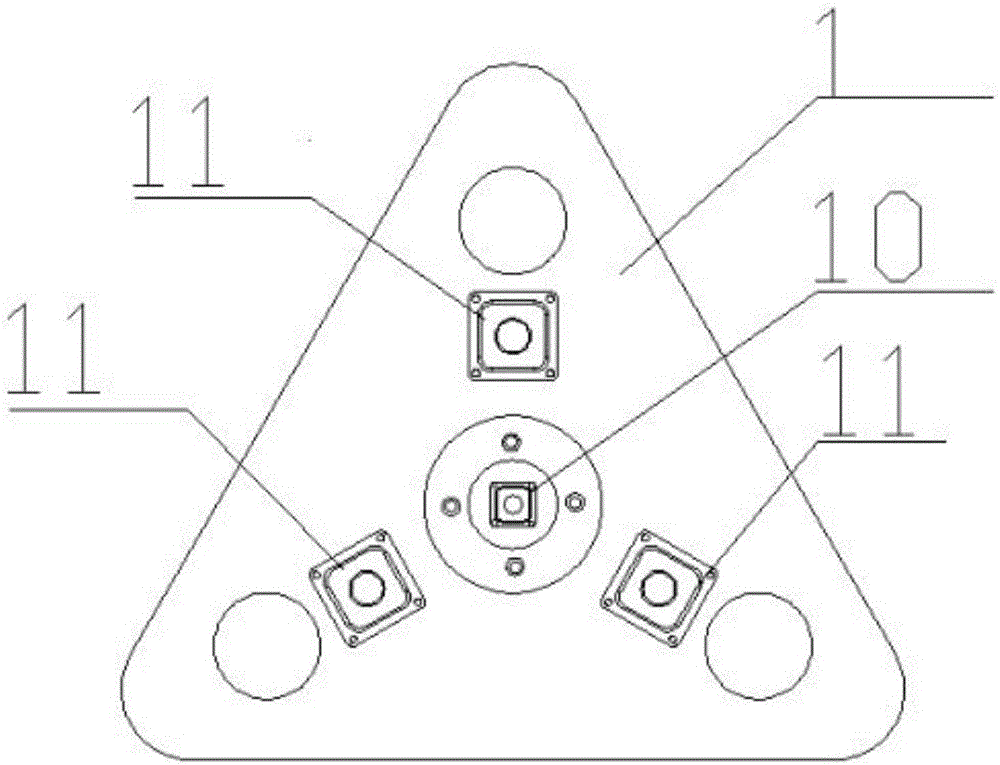

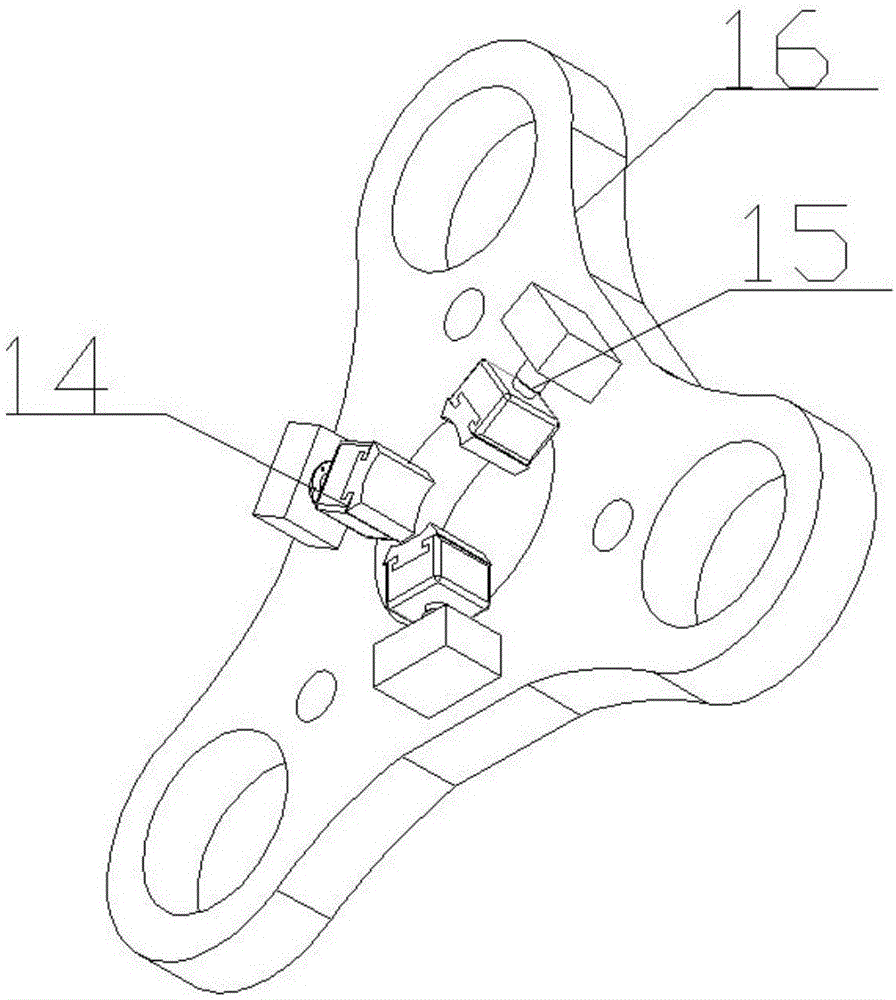

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] refer to figure 1 , figure 2 , image 3 and Figure 4 , an intelligent detection and correction device for an aero-engine main shaft, comprising a base 23, the base 23 is connected to the lower ends of three columns 2 that are evenly distributed around the circumference, and the middle and upper parts of the columns 2 are respectively connected with a lower fixing plate 1 and an upper fixing plate 7. , the lower part of the column 2 is sequentially connected with a lower clamping plate 20, a shape-correcting plate 19, and an upper clamping plate 16 from bottom to top;

[0024] A grating ruler guide rail 4 is fixed between the upper fixing plate 7 and the lower fixing plate 12, the grating ruler 3 connected on the grating ruler guide rail 4 is provided with a grating ruler displacement sensor slider 8 on the grating ruler guide rail 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com