Fixed-length flying saw sawing method and sawing device for achieving same

A sawing and flying sawing technology, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine accessories, etc., can solve the problems of unsatisfactory sawing accuracy, reduced service life of saw blades, and fluctuations in material moving speed, etc., to achieve Avoid damage to the sawing mechanism, improve positioning accuracy, and achieve the effect of organic combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

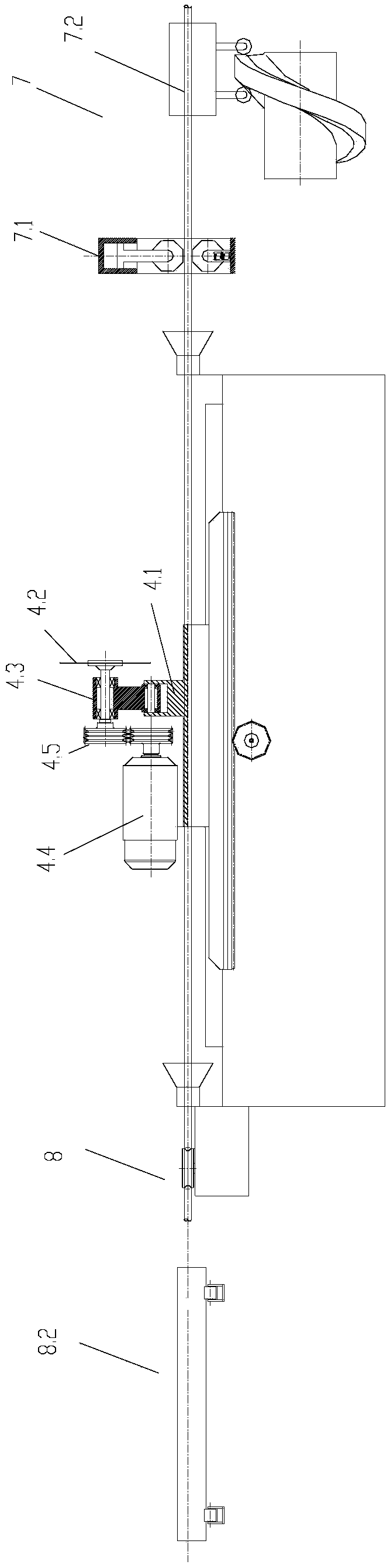

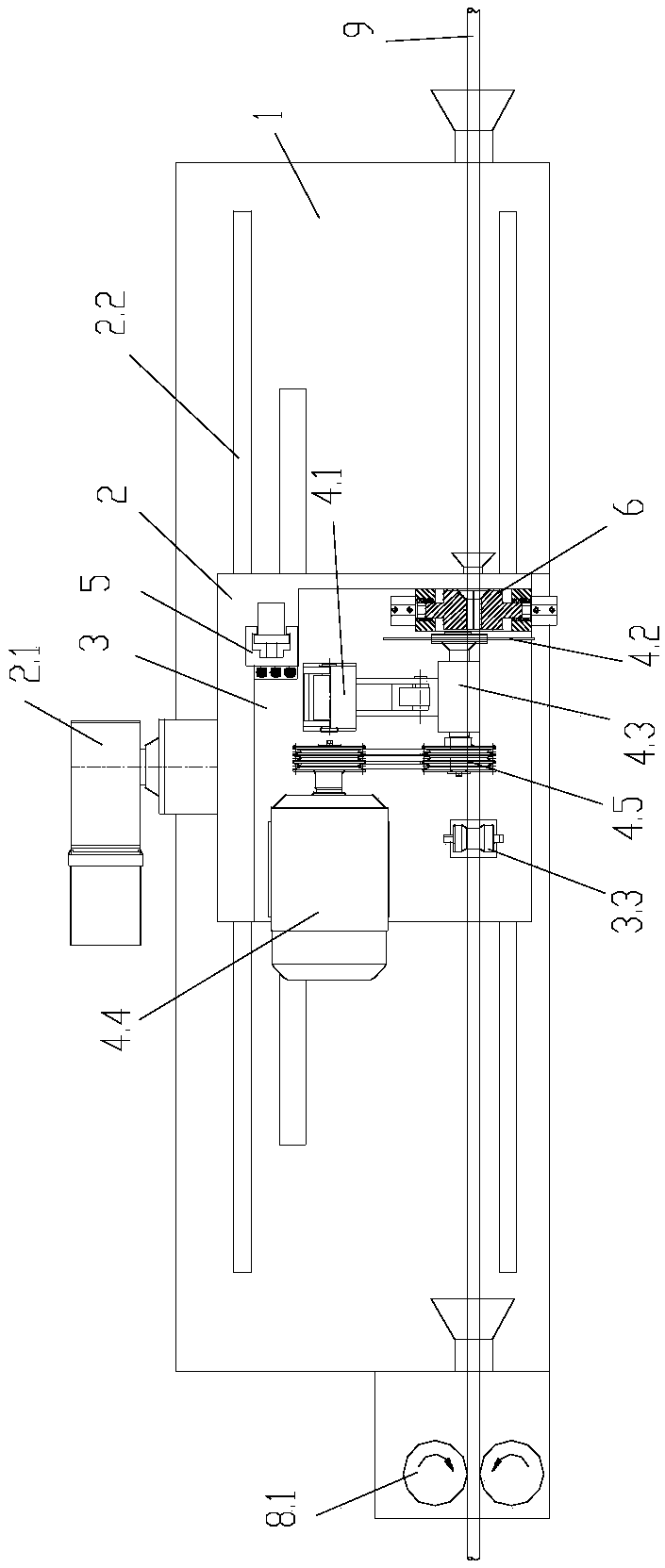

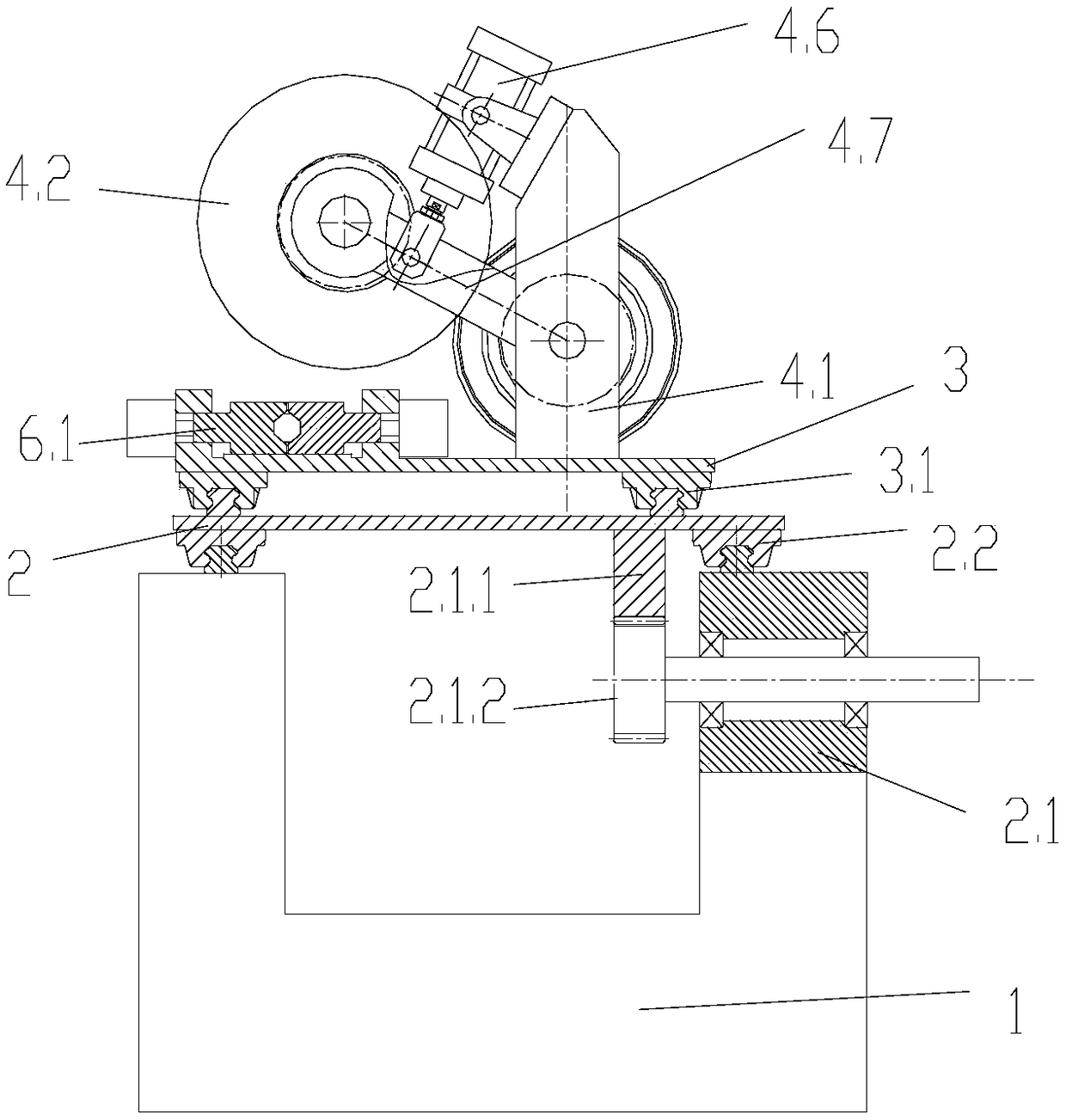

[0037] This embodiment is a fixed-length flying saw sawing method, which includes a speed-tracking process and a synchronous sawing process; The cutting mechanism 4 moves with acceleration and deceleration until the moving trolley 2 is synchronized with the moving speed of the material and the sawing mechanism 4 is positioned between the preset sawing position of the material; during the acceleration and deceleration process of the moving trolley 2, the floating car body 3 passes through the floating positioning structure 5 is relatively fixed with the mobile trolley 2, and the mobile trolley 2 moves synchronously with the floating car body 3 and the sawing mechanism 4;

[0038] The synchronous sawing process refers to: after the mobile car 2 is synchronized with the moving speed of the material, the mobile car 2 continues to drive the floating car body 3 and the sawing mechanism 4 to move; the floating car body 3 and the material are fixed to realize the floating car body 3 i...

Embodiment 2

[0053] The difference between the sawing method of the fixed-length flying saw in this embodiment and the first embodiment is that in this embodiment, when the moving speed of the material fluctuates, the floating positioning structure moves due to the push-pull force exerted by the material on the floating car body, which means: The floating positioning structure is an elastic component, and the elastic component exerts a preset support force on the moving trolley and the floating car body in the moving direction of the material. When the moving speed of the material fluctuates, the external force ≥ the preset supporting force on the floating positioning structure, the floating car body passes The floating positioning structure can move relative to the mobile car; when the floating positioning structure is not subjected to external force or the external force is less than the preset support force, the floating positioning structure makes the mobile car and the floating car rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com