Punching device for hardware product

A punching device and product technology, applied in positioning devices, feeding devices, manufacturing tools, etc., can solve problems such as equipment damage, reduced work efficiency, and complex structures, and achieve the effects of ensuring safety, accurate drilling, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

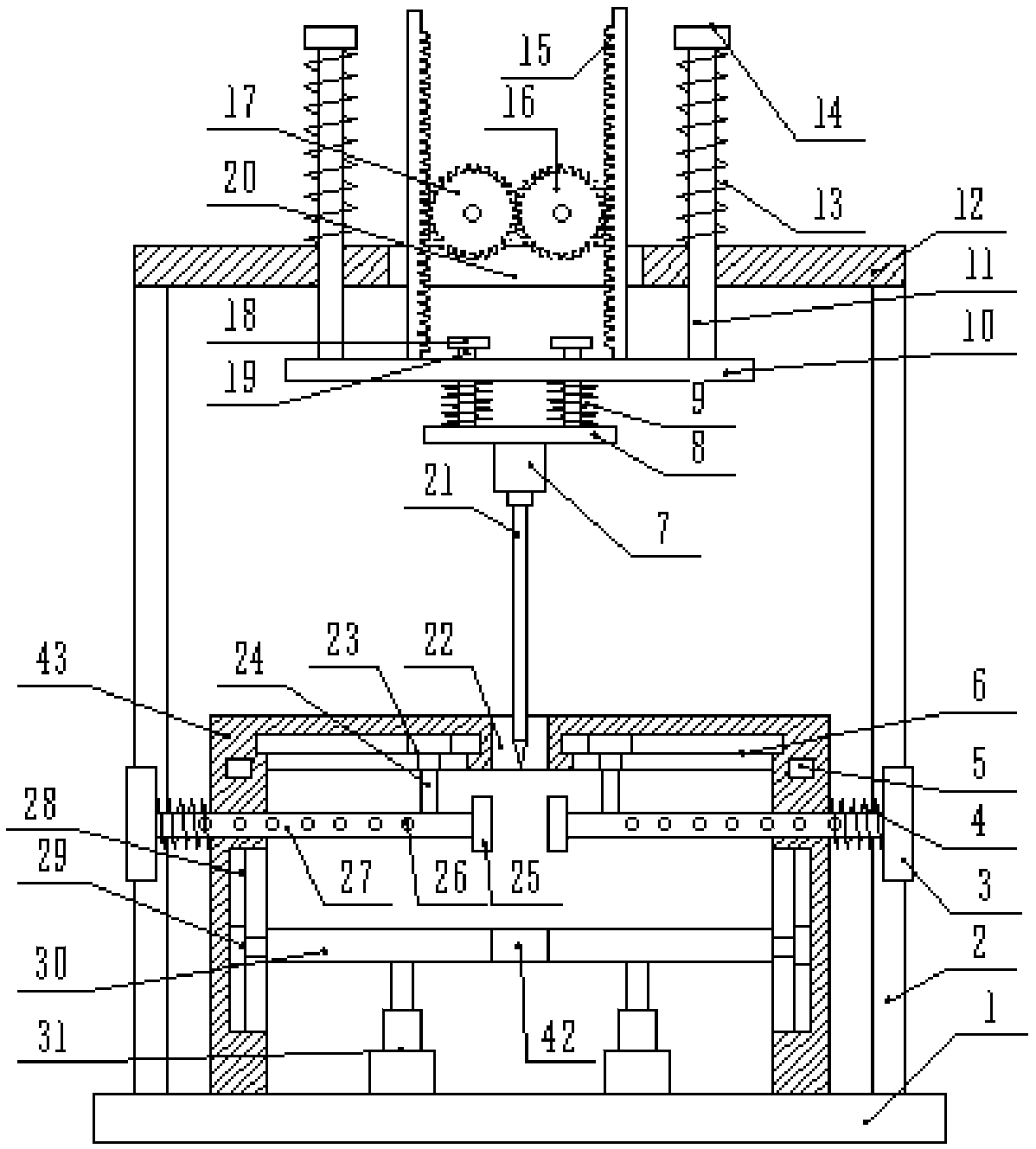

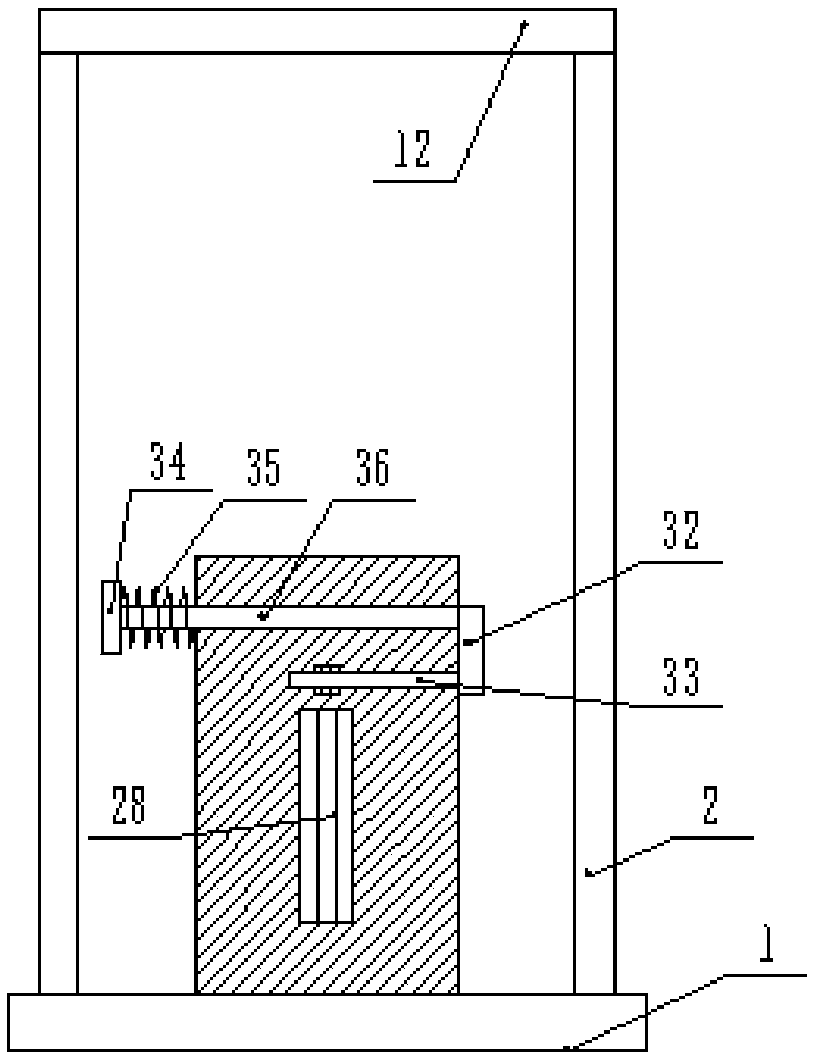

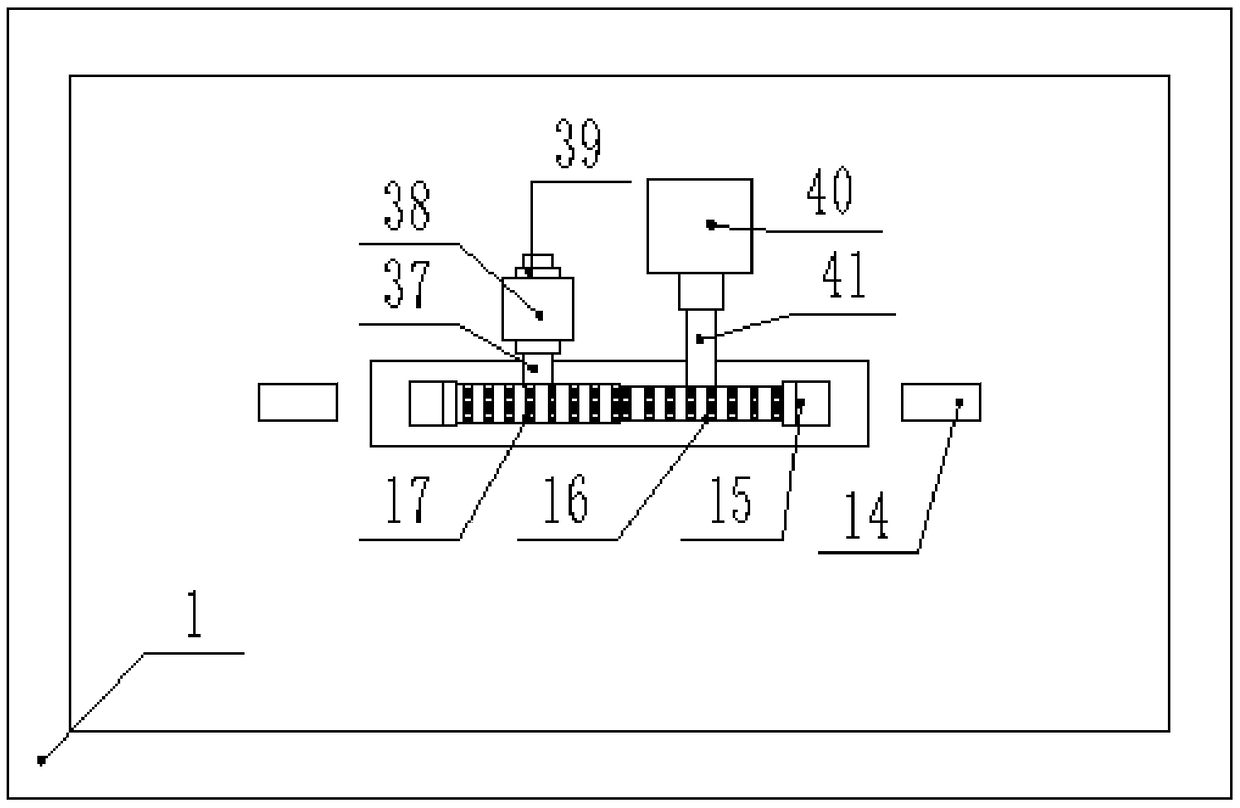

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a punching device for hardware products includes a base 1, the four corners of the top surface of the base 1 are fixedly connected with outriggers 2, and the tops of the four outriggers 2 are fixedly connected with the same support plate 12. A second through hole 20 is provided in the middle of the support plate 12, a second motor 40 is fixedly connected to the top surface of the support plate 12, and a second rotating rod 41 is fixedly connected to the output end of the second motor 40. One end of the rotating rod 41 is covered with a driving gear 16 and is fixedly connected with it. The driving gear 16 is meshed with a driven gear 17, and one side of the driven gear 17 is fixedly connected with a first rotating rod 37. The rotating rod 37 is covered with a fixed block 38 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap