Auxiliary shaving element for blade on shaving equipment

A component and blade technology, applied in the field of auxiliary shaving components, can solve the problems of limited pulling ability, tingling discomfort, poor shaving degree, etc., to achieve a comfortable shaving experience, flexible selection of materials, and improved shaving. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

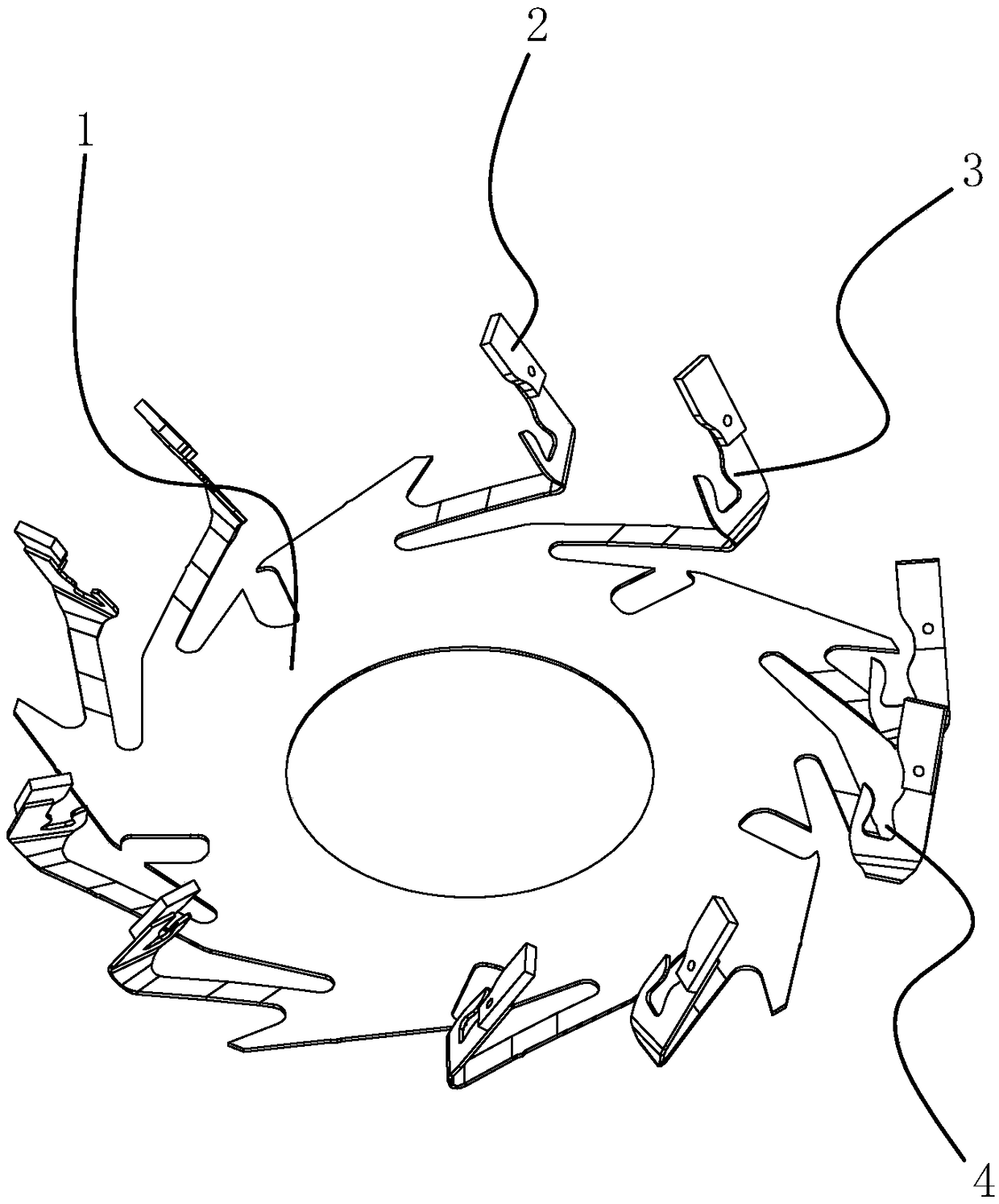

[0028] Such as figure 1 , figure 2 As shown, an auxiliary shaving element used for blades on shaving equipment includes a hair-pull base layer 1 and a thickened layer 2. There are several bent and inclined elastic arms 3 on the hair-pull base layer 1, and the outer ends of the elastic arms 3 Welding or bonding thickened layer 2. After the elastic arm 3 of the stretch base layer 1 is connected to the thickened layer 2, the uppermost end of the thickened layer 2 is distributed on a circular track after being formed by bending. At the same time, due to the split structure, the thickness of the thickened layer 2 is selected according to the needs of the auxiliary shaving effect.

[0029] Under the high-speed rotation of the rotary razor blade, the front thickened layer 2 of the blade can be slightly embedded in the hair, and the elasticity of the hair-pull base layer 1 can be used to stick to the edge of the blade and move down and gently pull the beard until the edge of the bl...

Embodiment 2

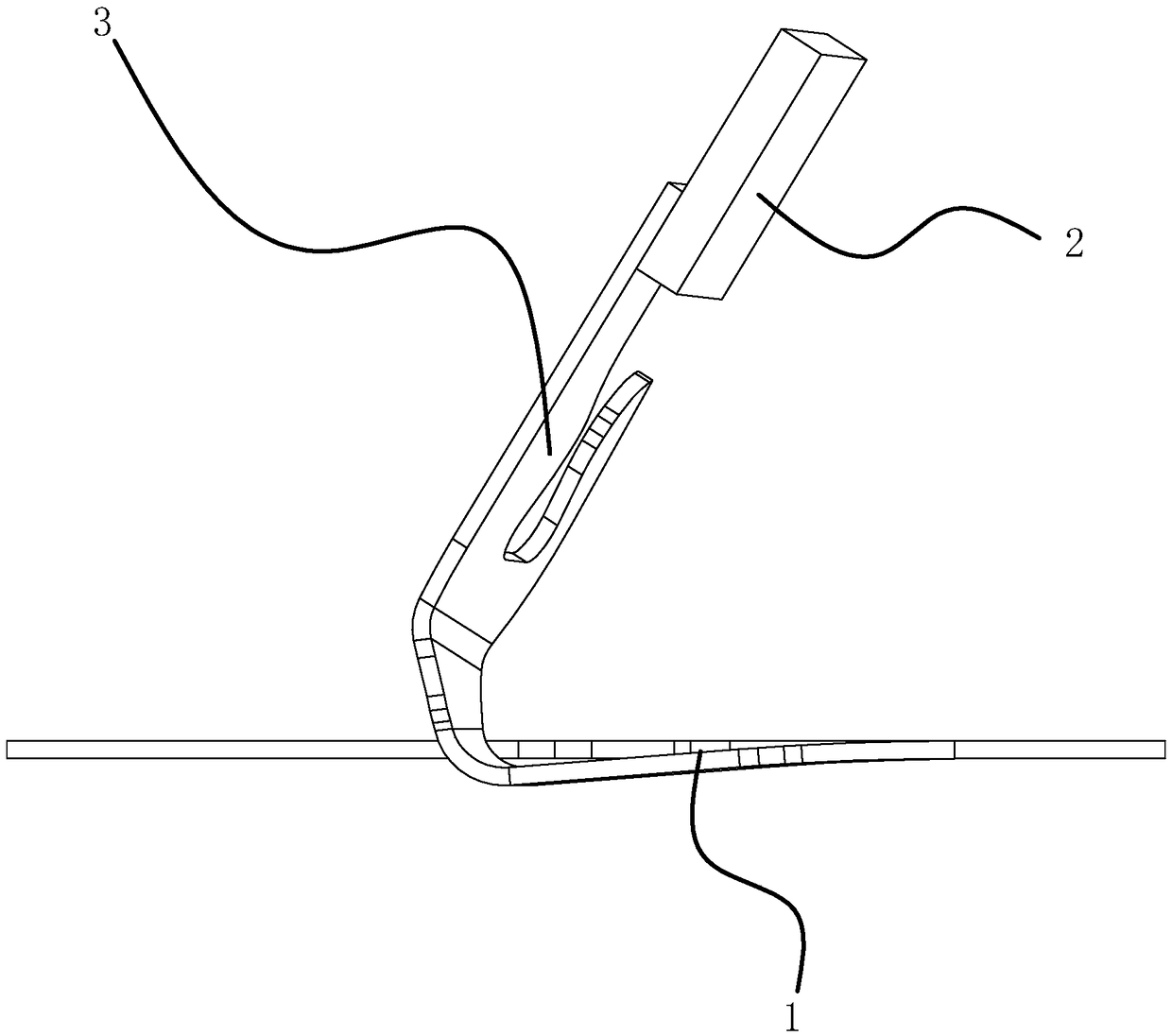

[0034] Such as image 3 As shown, there are two thickened layers 2 on each elastic arm 3, the two thickened layers 2 are overlapped and bonded together, and the two thickened layers 2 are connected together by bonding.

[0035] The thickened layer 2 is located on the upper surface of the elastic arm 3, the inner end of the thickened layer 2 is closely connected with the outer end of the elastic arm 3, and the outer end is suspended.

[0036] The elastic arm 3 is provided with a bayonet 4, and the bayonet 4 is a groove formed after stamping. The buckle can be used to snap into the knife arm of the corresponding blade to ensure the correctness of the assembly position of the thickened layer 2 on the pulling base 1 and the cutting edge of the blade. During the pulling process of the elastic arm 3 and the thickened layer 2, Always maintain the position and distance between the thickened layer 2 and the blade edge, so that it can pull the beard stably and reset quickly and accurat...

Embodiment 3

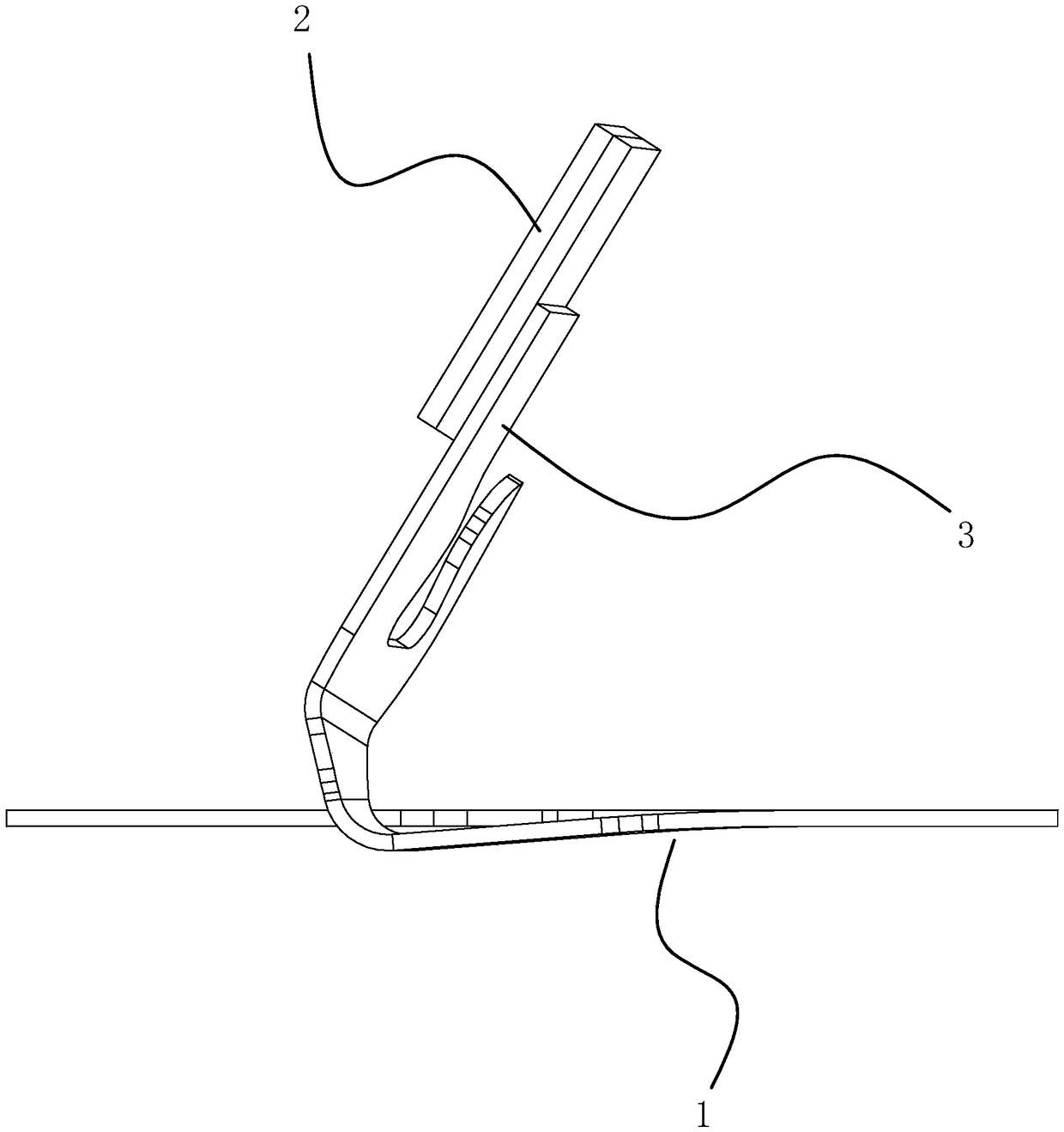

[0038] Such as Figure 4 As shown, the difference from the third embodiment is that the outer end of the thickened layer 2 is flush with the outer end of the elastic arm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com