Motor-driven pressing machine

A motor-driven, pressing machine technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of large cylinder volume and air consumption, bulky pressing machine, and uneconomical problems, so as to save space and save Transportation cost, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

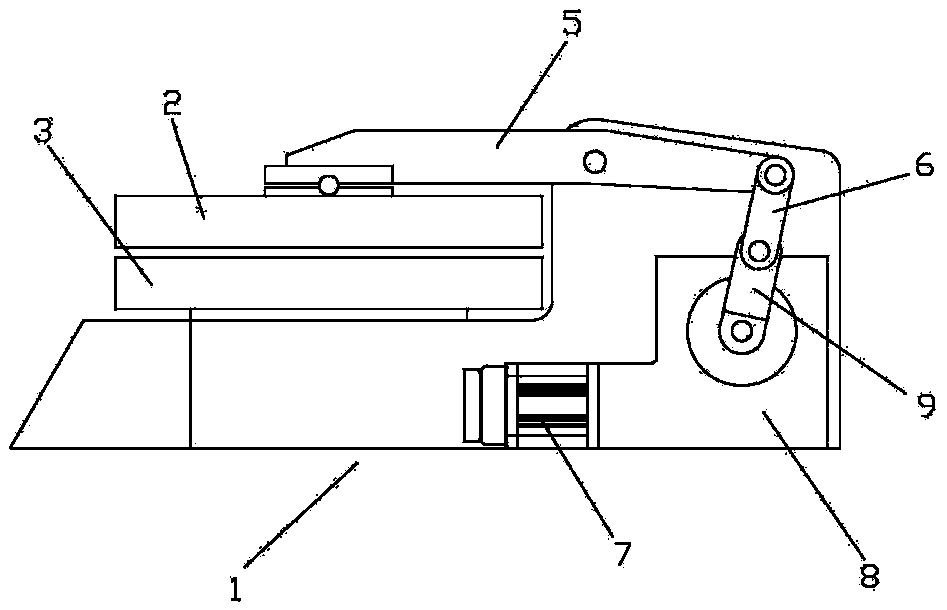

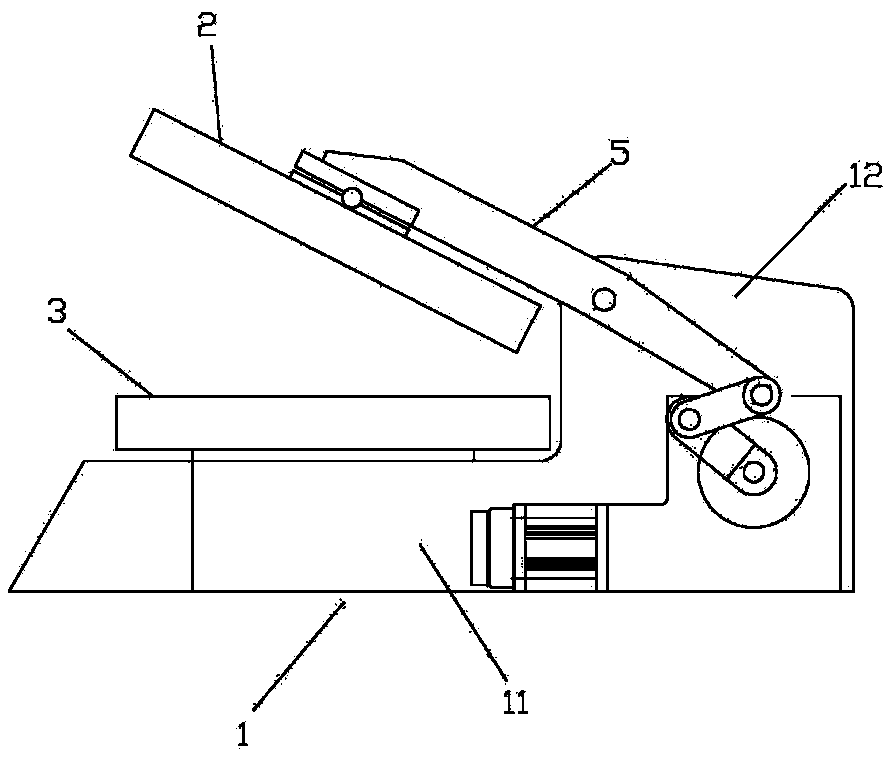

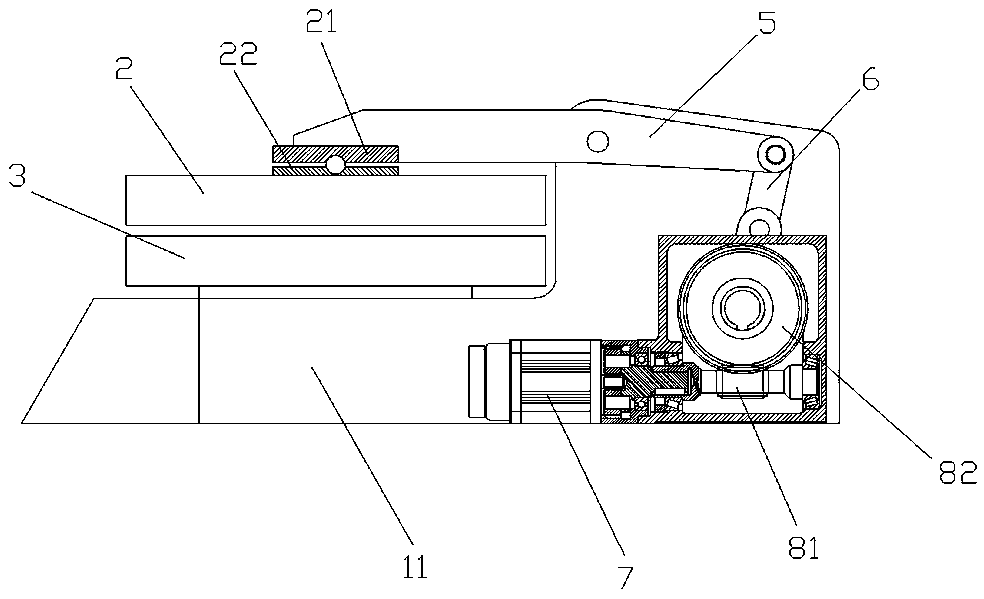

[0015] Such as Figure 1-4 As shown, a motor-driven pressing machine includes a base 1, a pressing device and a controller, the pressing device includes an upper pressing plate 2 and a lower pressing plate 3, and the base 1 includes a base 11 and connecting seat 12, the connecting seat 12 is set on the top of the rear side of the base 11, the lower pressing plate 3 is fixed on the top of the front side of the base 11, and the upper pressing plate 2 is set on the front end of the rocker arm 5 The middle part of the rocker arm 5 is pivotally connected to the connecting seat 12, and the upper pressing plate 2 is fixed on the front end of the rocker arm 5 through the upper connecting plate 21 and the lower connecting plate 22 pivotally connected to each other; the rear end of the rocking arm 5 The part is connected with the drive mechanism through the connecting rod 6; the drive mechanism includes a DC motor 7, a worm gear reducer 8 and an output arm 9, the DC motor 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com