Feeding and discharging station accurately aligning transferring machine

A feeder and station technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as low efficiency and small load, and achieve stable operation, ensure stability and safety, and high connection The effect of rebuttal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

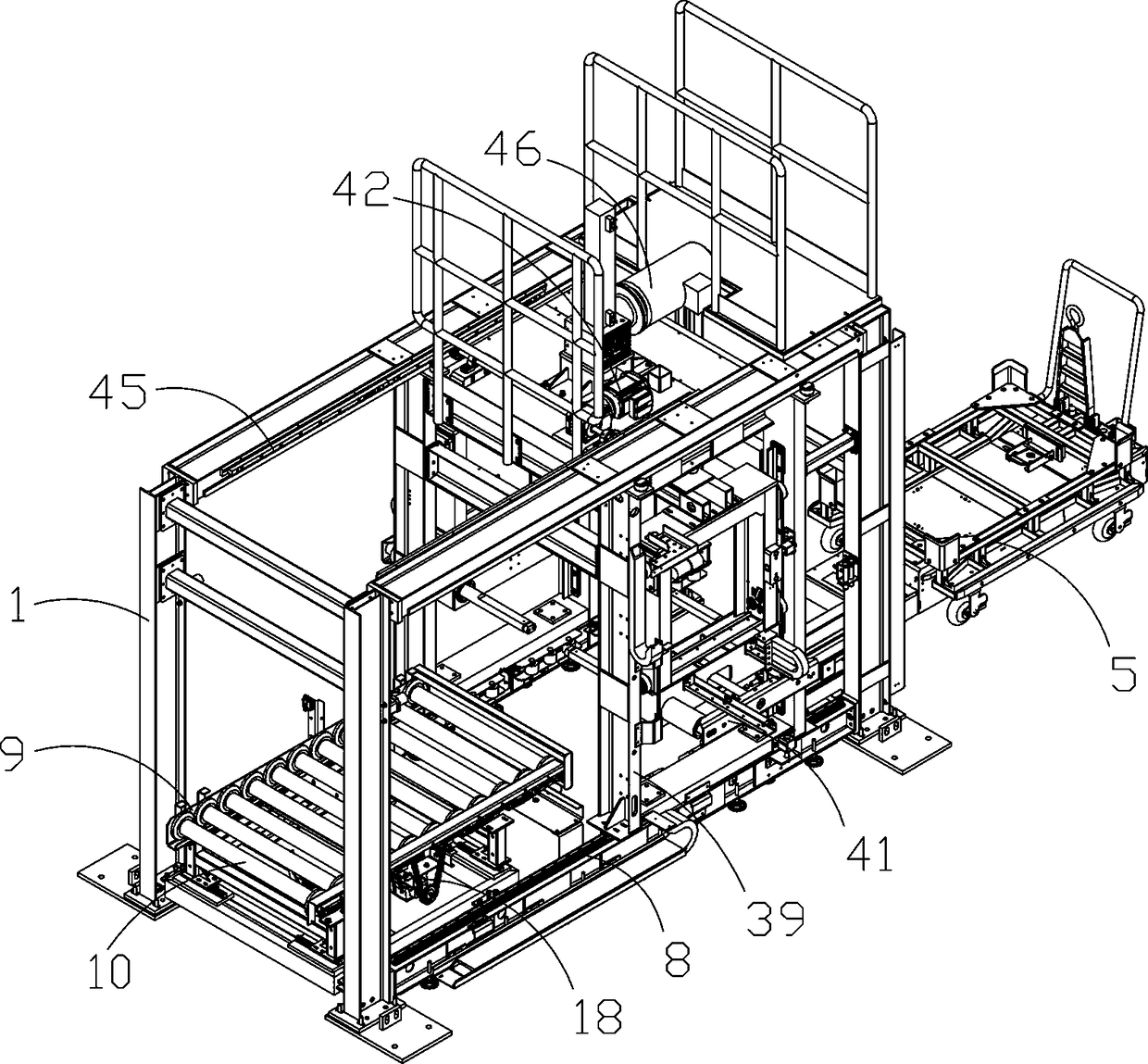

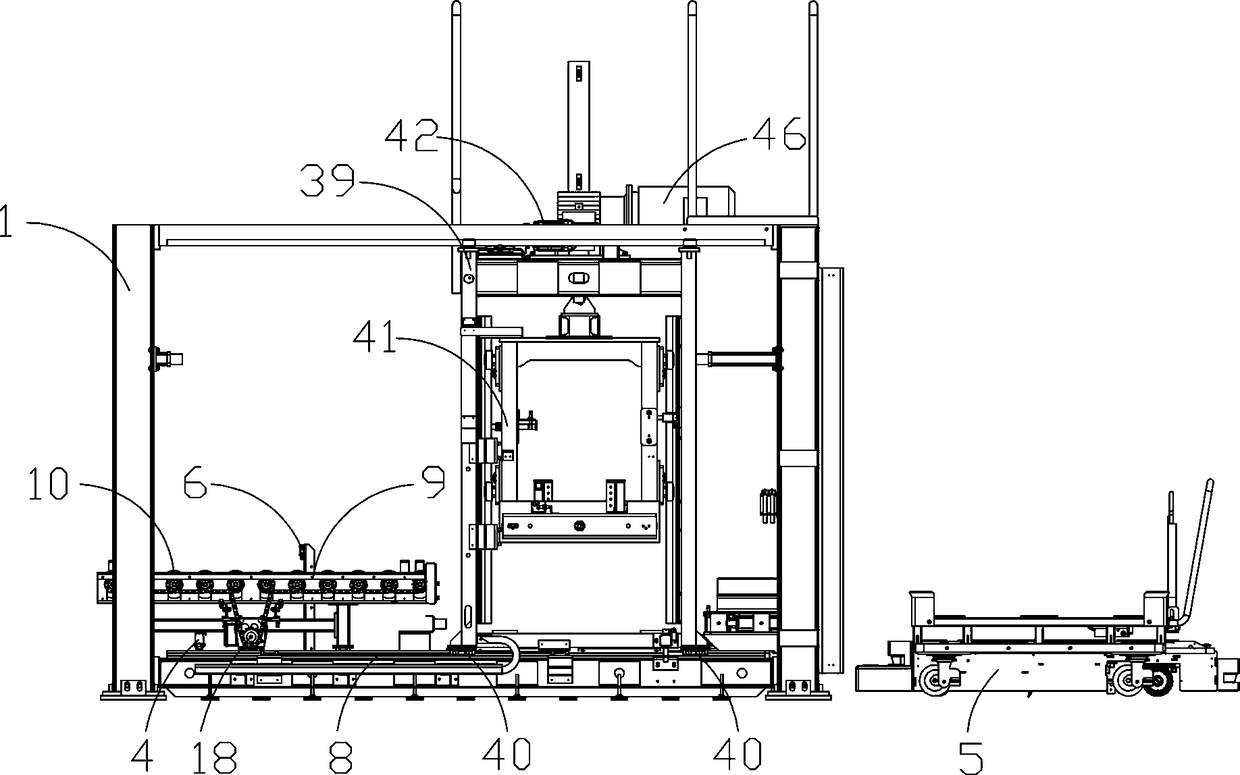

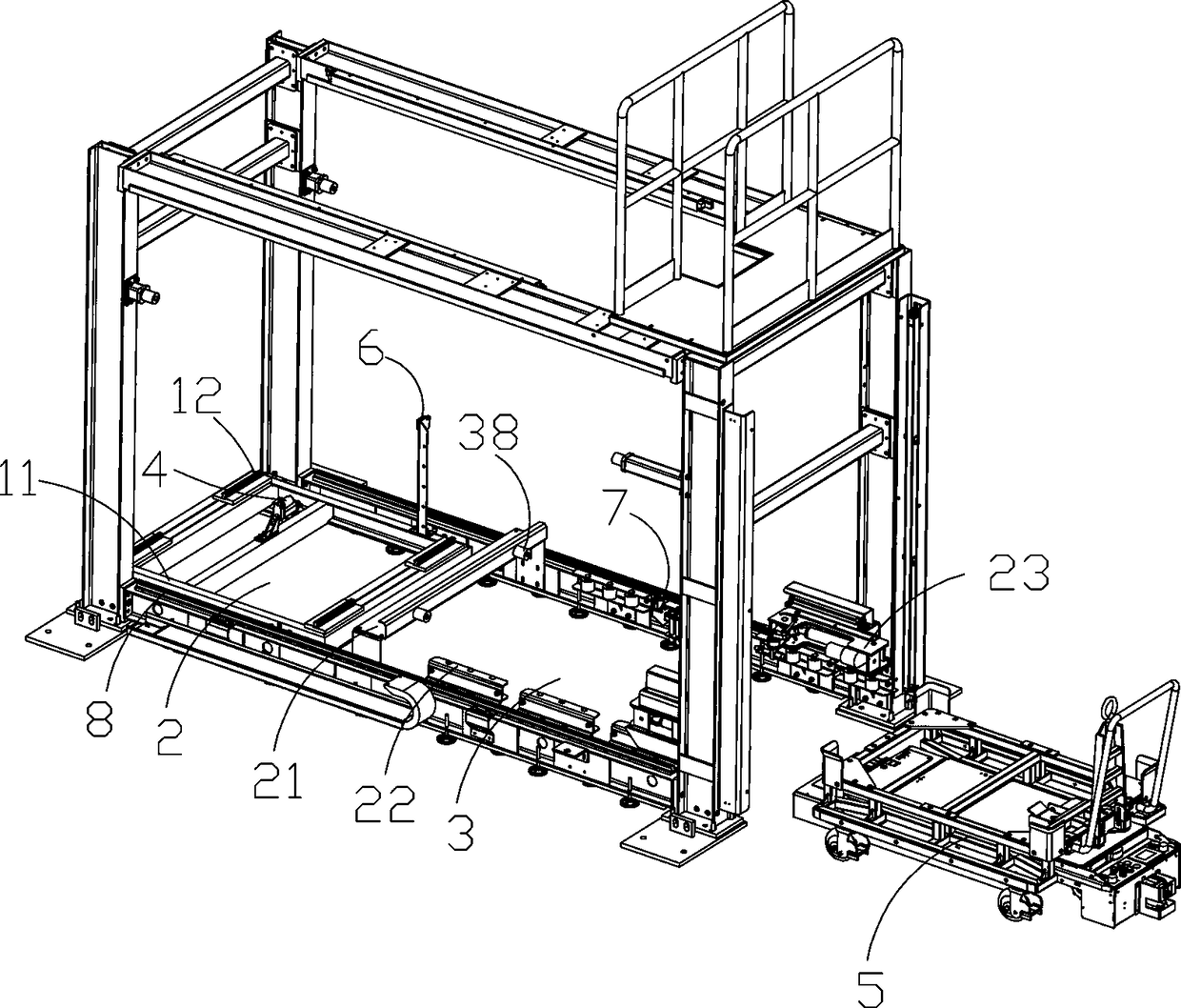

[0034] see Figure 1-3 , a splicing machine that realizes precise alignment of the feeding and discharging stations, has a horizontally arranged fixed frame 1, and the lower side of the fixed frame 1 is provided with a left and right oppositely arranged feeding station 2 and an outlet. Material station 3; the feed station 2 is provided with a barge conveyor, and the barge conveyor is driven by the push rod A4 to move longitudinally on the feed station 2; the discharge station 3 is used for parking and receiving The material trolley 5 and the material receiving trolley 5 are AGC trolleys, and can also be hand-push trolleys; a correction mechanism for horizontally correcting the orientation of the material receiving trolley 5 is provided on the discharge station 3; Positions 2 and 3 correspond to the distance sensor A6 and distance sensor B7 used to detect the longitudinal offset of the barge conveyor and the receiving trolley. The distance sensors A6 and B7 are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com