Retractable fork device

A telescopic fork and sprocket technology, applied in the direction of lifting devices, etc., can solve the problems of high precision requirements, time-consuming and labor-consuming, and weak system stability, and achieve the reduction of processing and manufacturing precision requirements and installation and coordination precision requirements, The effect of reducing the complexity and weight of the structure and improving the efficiency of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

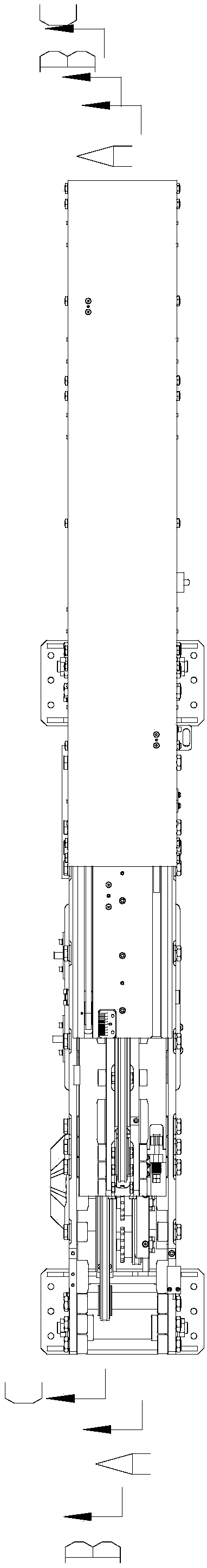

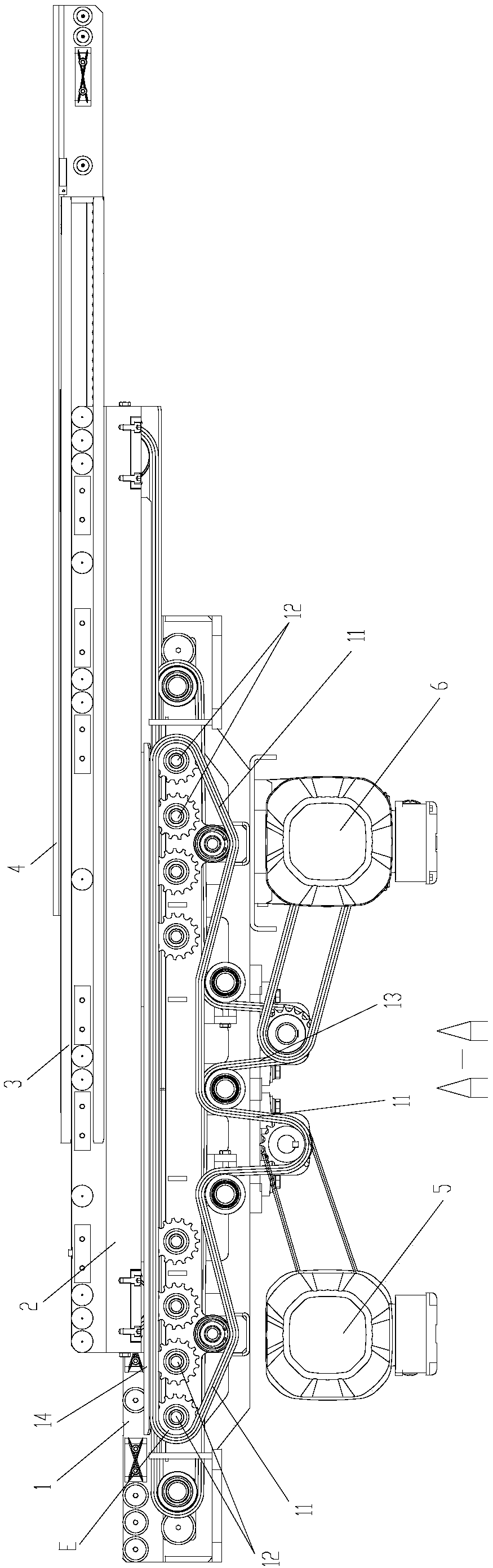

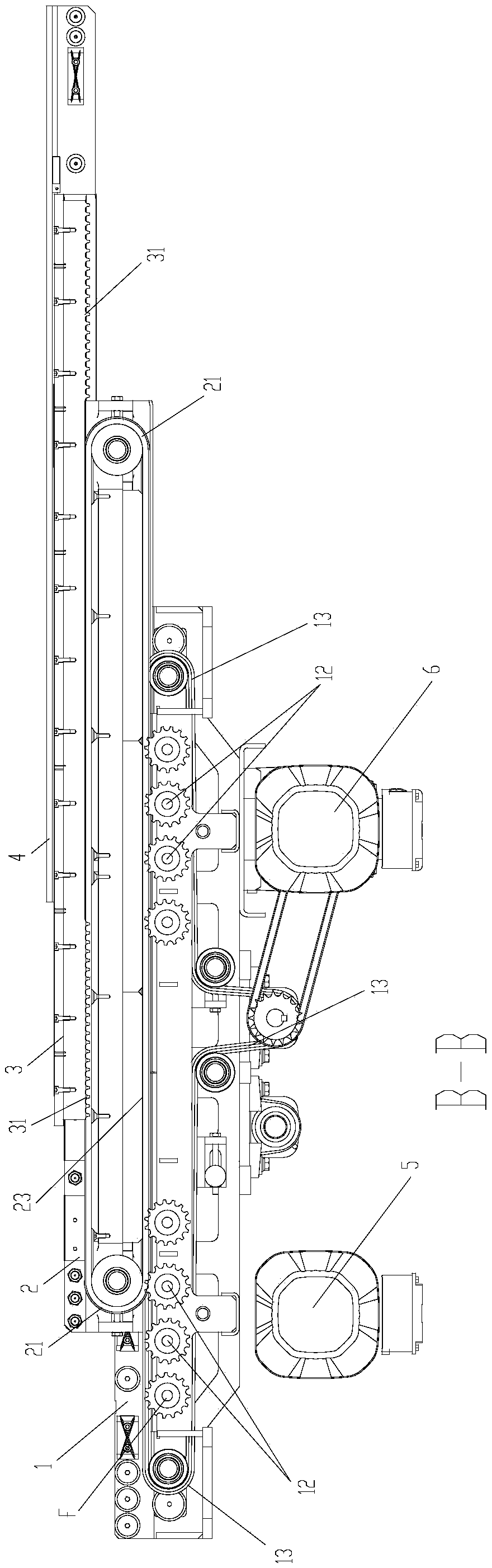

[0026] like Figure 1 to Figure 4 As shown, the present invention provides a telescopic fork device, comprising a first-level fork 1, a second-level fork 2, a third-level fork 3 and a fourth-level fork 4 arranged in sequence, and the first-level fork 1 is provided with a plurality of fixing components ( not shown in the figure), for fixing the device on other equipment (such as lifting, mobile platform). The third-stage fork 3 and the fourth-stage fork 4 are linked, and the first-stage fork 1 is provided with a circle of the first sprocket assembly 11 (it can be expected that the sprocket assembly must include a plurality of driven wheels and a circle wound on the plurality of driven wheels. chain). A circle of second sprocket assembly 21 is provided on the secondary fork 2 (it can be expected that the sprocket assembly must also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com