A kind of thermosetting artificial board starch adhesive and preparation method thereof

A technology for starch adhesives and wood-based panels, applied in the direction of adhesive heating, adhesives, adhesive products, etc., can solve problems such as excessive expansion, poor heat resistance, and adhesive layer decomposition, and achieve improved thermal stability and performance. The effect of water resistance, widening application fields, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

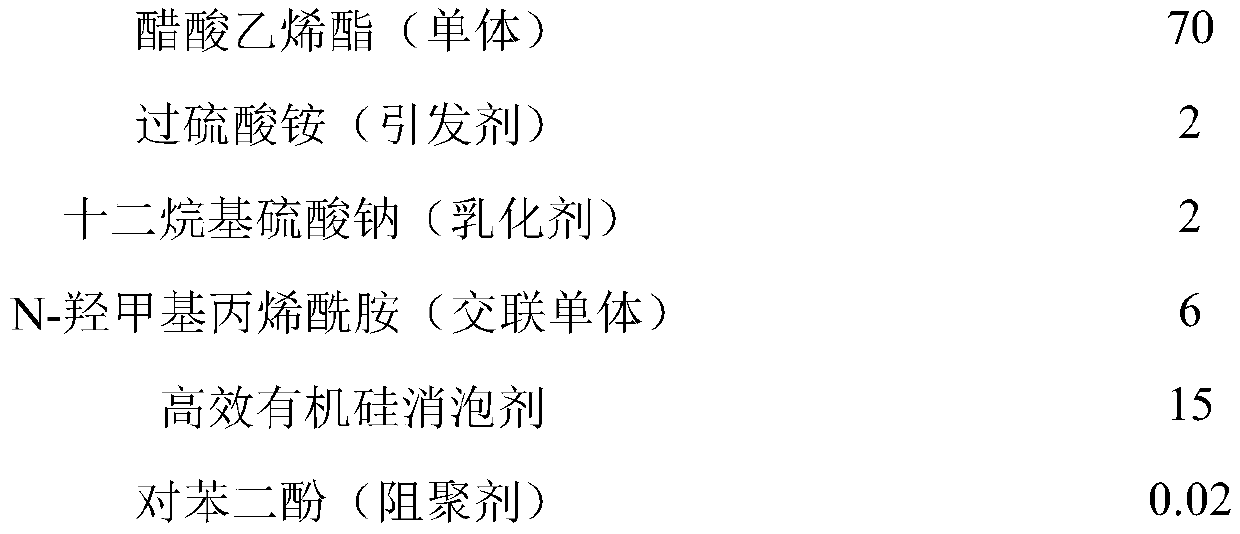

[0042] Formula (mass percentage):

[0043]

[0044]

[0045] Process flow:

[0046] (1) Prepare an emulsion with a mass concentration of 35% from cornstarch, acidify it with hydrochloric acid at 60°C for 2 hours, then adjust the pH to about 3-5 with sodium hydroxide, raise the temperature to 90°C, and keep it warm for 0.5h, Then cool down to 70°C.

[0047] (2) Slowly drop the pre-configured seed emulsion into the reaction kettle, the stirrer speed is about 300r / min, observe the condenser tube, when the reflux liquid is significantly reduced;

[0048] (3) Add the initiator of remaining total addition 50% in the reactor, slowly add dropwise remaining monomer solution, dropwise time is 3h, add the initiator of 15% total addition to continue reaction 1.5h;

[0049] (4) Slowly add the N-methylolacrylamide solution of 10% mass concentration prepared in advance and the initiator accounting for 35% of the total initiator addition to the reaction kettle dropwise within 2 hours,...

Embodiment 2

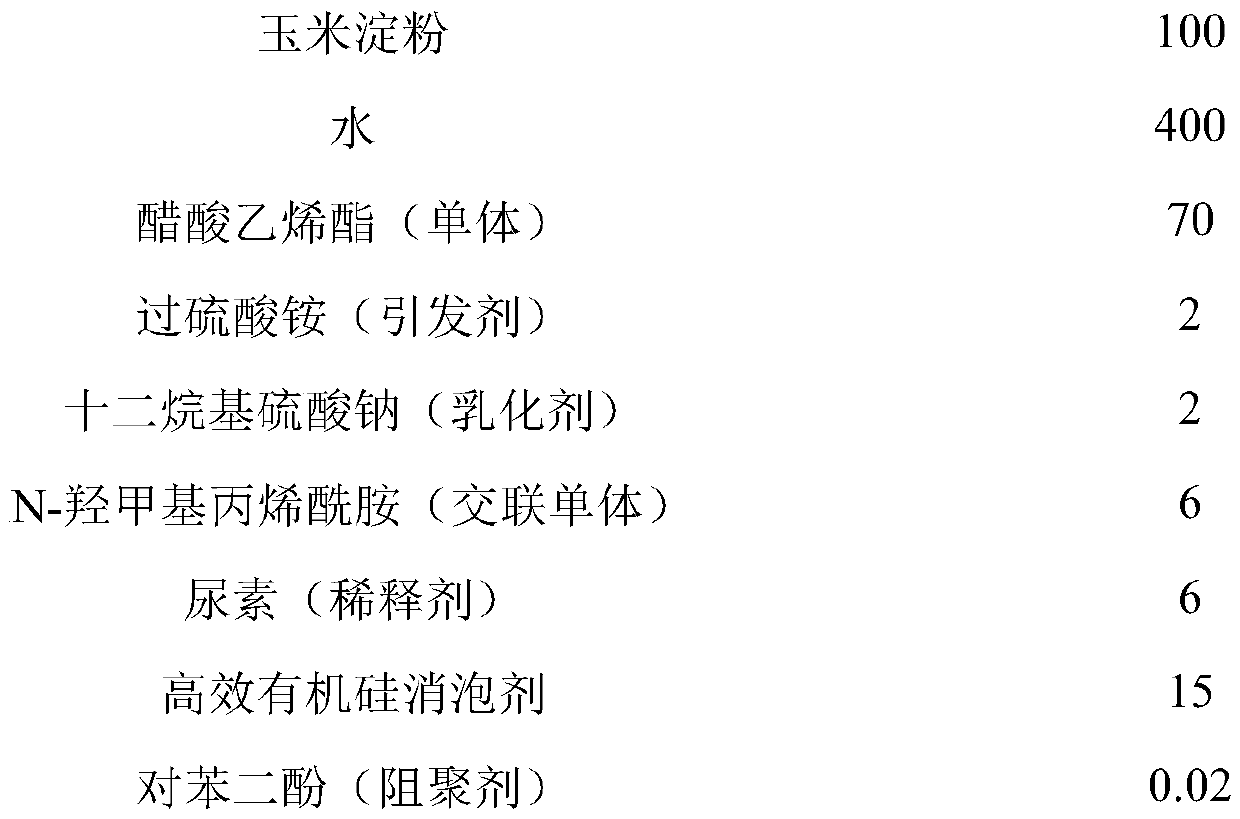

[0053] Formula (mass percentage):

[0054]

[0055] Process flow:

[0056] (1) Prepare an emulsion with a mass concentration of 35% using cornstarch as a raw material, acidify it with hydrochloric acid at 60°C for 2 hours, then adjust the pH to about 3-5 with sodium hydroxide, add urea, heat up to 90°C, and keep it warm 0.5h, then lower the temperature to 70°C.

[0057] (2) Slowly drop the pre-configured seed emulsion into the reaction kettle, the stirrer speed is about 300r / min, observe the condenser tube, when the reflux liquid is significantly reduced;

[0058] (3) Add the initiator of remaining total addition 50% in the reactor, slowly add dropwise remaining monomer solution, dropwise time is 3h, add the initiator of 15% total addition to continue reaction 1.5h;

[0059] (4) Slowly add the N-methylolacrylamide solution with a mass concentration of 10% prepared in advance and the initiator accounting for 35% of the total initiator addition to the reaction kettle dropwi...

Embodiment 3

[0063] Formula (mass percentage):

[0064]

[0065] Process flow:

[0066] (1) Prepare an emulsion with a mass concentration of 35% using cornstarch as a raw material, acidify it with hydrochloric acid at 60°C for 2 hours, then adjust the pH to about 3-5 with sodium hydroxide, add urea, heat up to 90°C, and keep it warm 0.5h, then lower the temperature to 70°C.

[0067] (2) Slowly drop the pre-configured seed emulsion into the reaction kettle, the stirrer speed is about 300r / min, observe the condenser tube, when the reflux liquid is significantly reduced;

[0068] (3) Add the initiator of remaining total addition 50% in the reactor, slowly add dropwise remaining monomer solution, dropwise time is 3h, add the initiator of 15% total addition to continue reaction 1.5h;

[0069] (4) After the addition of the monomers is completed, the temperature is raised to 85°C and kept for 0.5h to volatilize the residual monomers, and the temperature is lowered to 50°C to add a hydroquino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com