Washing machine control method and washing machine

A control method and washing machine technology, applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of noise, large drainage, etc., and achieve the effects of reducing noise, reducing startup noise, and avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

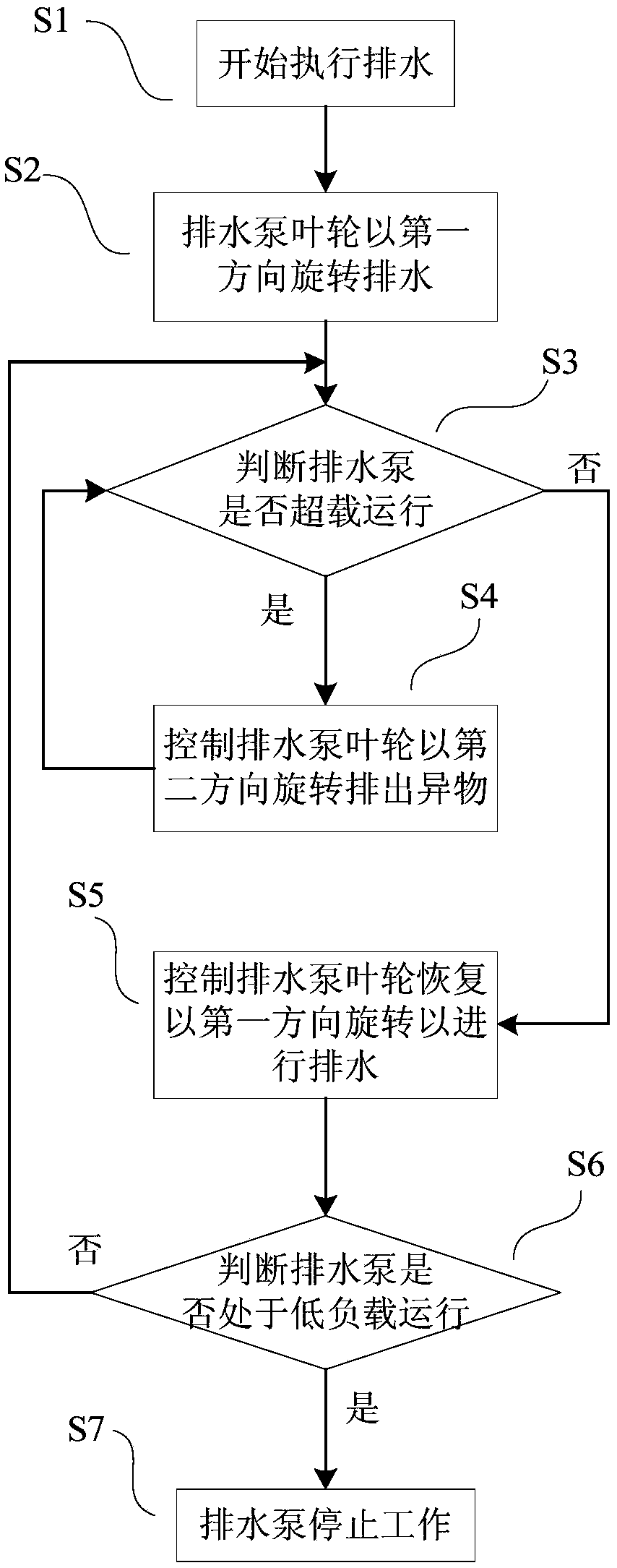

[0054] In this example, if figure 1 As shown, a washing machine control method is provided. The washing machine includes a drain pump, and the drain pump is equipped with an impeller driven by the drain pump motor to rotate, and the impeller can be controlled to change the direction of rotation; The detected value is compared with the set value to judge whether there is any foreign matter that interferes with the rotation of the impeller, and when the interference occurs, the direction of impeller rotation is changed to discharge the foreign matter.

[0055] In this embodiment, the drain pump of the washing machine is equipped with an impeller driven by a motor. During the drainage process, the impeller cavity is filled with discharged sewage. Since there are many impurities in the water, the foreign matter in it is easy to stay when the impeller starts and rotates in one direction. The impeller cavity interferes with the rotation of the impeller, which tends to increase the l...

Embodiment 2

[0073] The difference between this embodiment and embodiment 1 is:

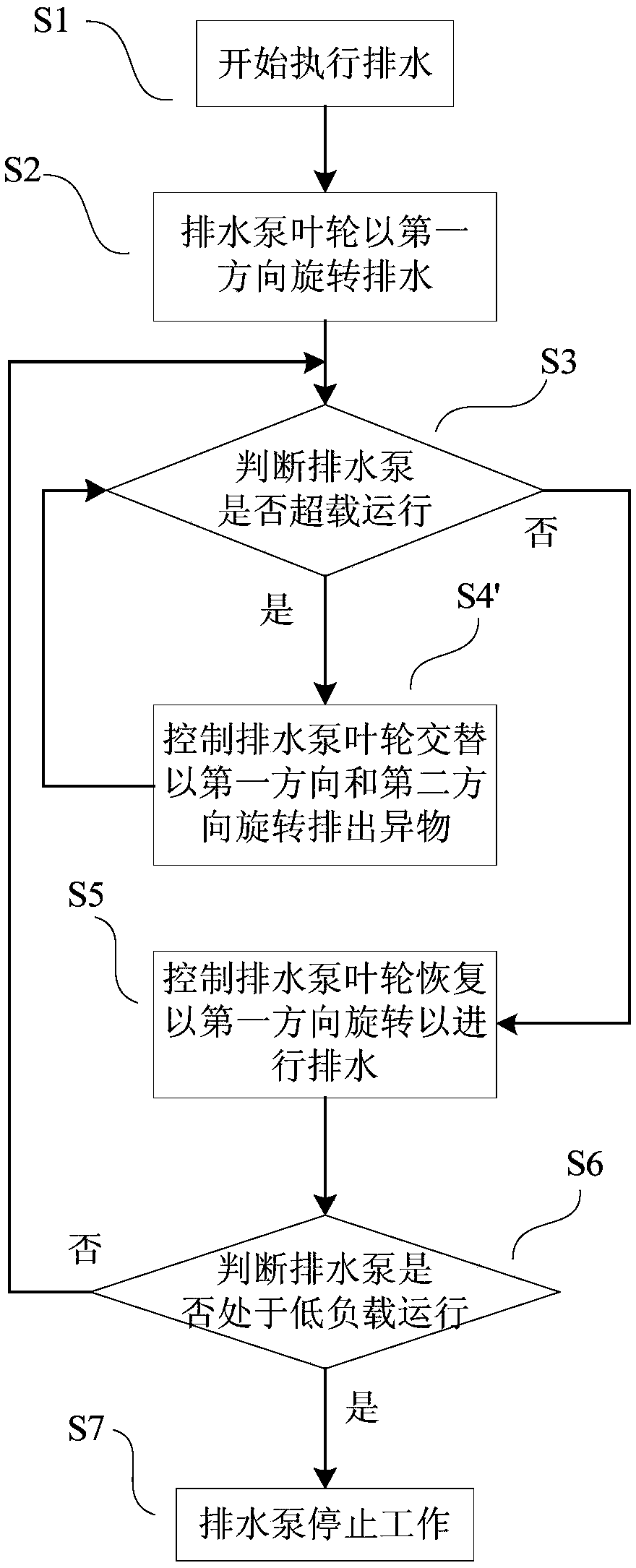

[0074] In this example, if figure 2 As shown, after it is determined that there is foreign matter interfering with the impeller, the washing machine controls the impeller of the drain pump to alternately rotate in the first direction and the second direction to discharge the foreign matter.

[0075] In this embodiment, when the foreign matter is difficult to discharge and the noise continues, the impeller is controlled to alternately rotate in the first direction and the second direction, and the foreign matter is discharged by using the turbulence effect repeatedly generated by the fluid in the impeller cavity.

[0076] In this embodiment, the control method specifically includes the following steps:

[0077] S1. Start to perform drainage, and then perform step S2;

[0078] S2. The impeller of the drainage pump rotates in the first direction to drain water, and then execute step S3;

[0079] S3. Determin...

Embodiment 3

[0086] The difference between this embodiment and embodiment 1 is:

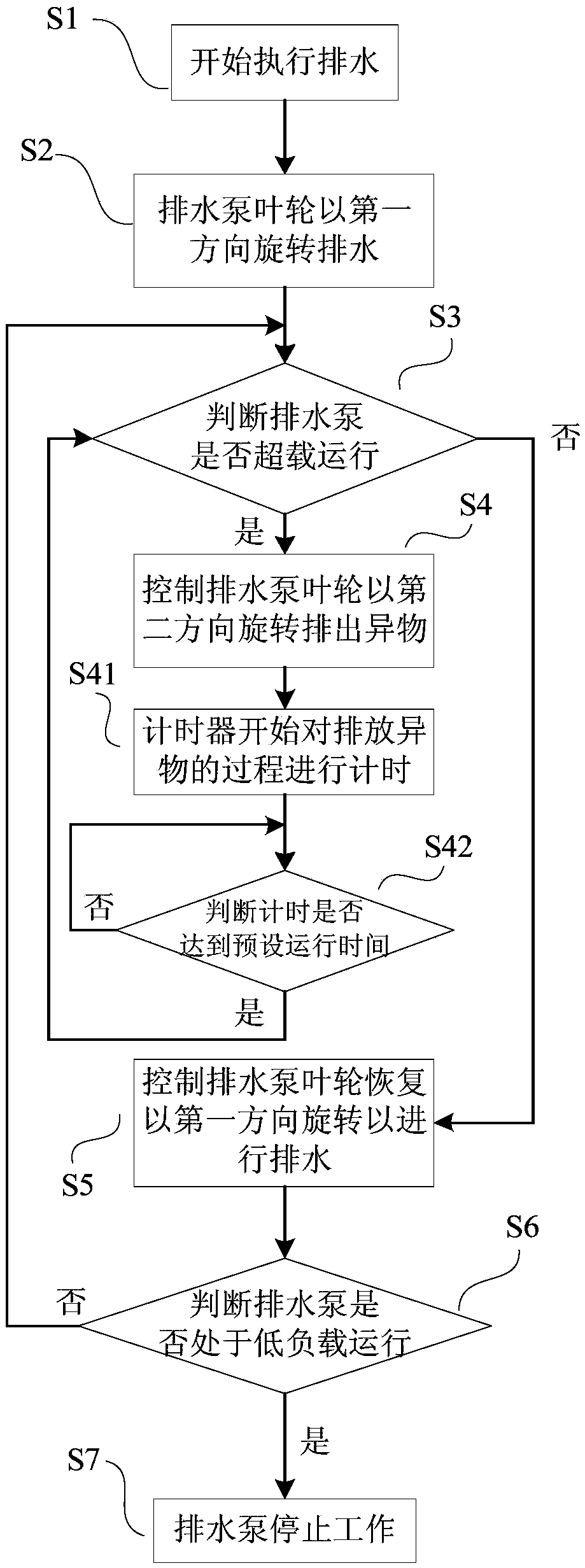

[0087] In this example, if image 3 As shown, the washing machine controls the impeller to rotate in the second direction and starts timing since the detection value of the working current of the drainage pump motor is greater than the first set value, and the timing ends after reaching the set time. The detection value is compared with the first set value, and the rotation direction of the impeller is adjusted according to the comparison result.

[0088] In this embodiment, the washing machine starts timing when the detection value of the working current of the drain pump motor is greater than the first set value, that is, when the impeller reverses and starts to discharge foreign matter, and judges whether the load is at a normal level when the preset foreign matter discharge time is reached. If it is normal, the drainage will resume, if it is not normal, adjust the direction of impeller rotation and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com