Coiled tubing speed tubular column suspending and sealing device

A speed string and sealing device technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of coiled tubing falling off, poor sealing reliability, time-consuming and labor-intensive, etc., to improve work efficiency, Avoid leakage problems, fast and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

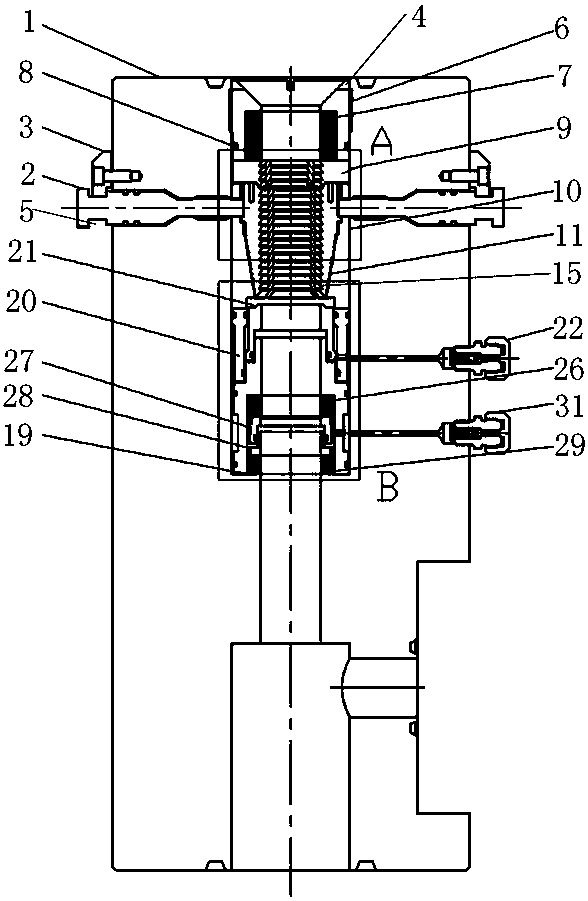

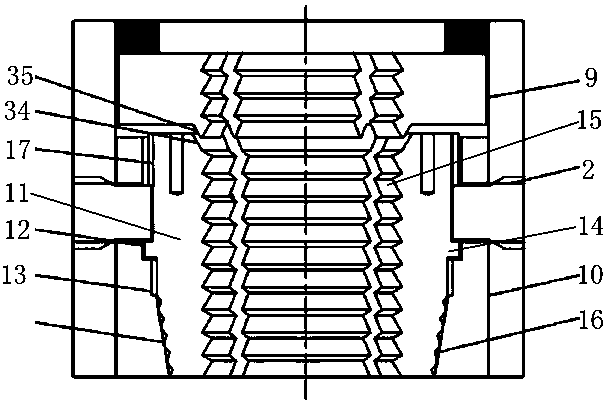

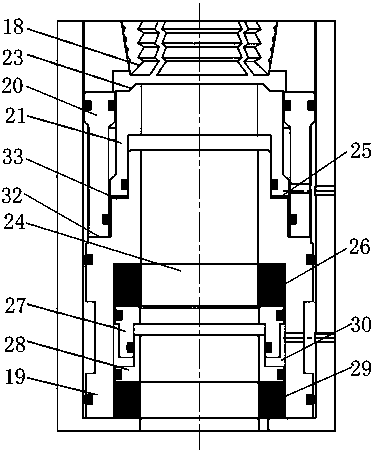

[0036] refer to Figure 1-Figure 6 As shown, a coiled tubing velocity string suspension sealing device includes a body assembly, a top sealing assembly, a slip assembly, an unlocking mechanism and a bottom sealing assembly.

[0037] in:

[0038] The body assembly includes a suspension body 1 , a slip activation pin 2 and a limit protection ring 3 . The slip activation pin 2 is installed on the outer peripheral surface of the suspension body 1, and one end thereof penetrates the suspension body 1 and is in movable contact with the outer surface of the slips. The limit protection ring 3 is arranged on the outer surface of the suspension body 1 to limit the unscrewing position of the slip activation pin, and the middle part of the suspension body 1 is provided with a suspension hole 4 for hanging the pipe string. The outer surface of the slip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com