Stepless variable internal combustion engine air inflow system

A technology of air intake system and internal combustion engine, which is applied in the direction of charging system, intake muffler, combustion air/combustion-air treatment, etc., can solve the problems of low practicality and reliability, achieve optimal charging efficiency, optimize the speed range, The effect of broad resonant frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments.

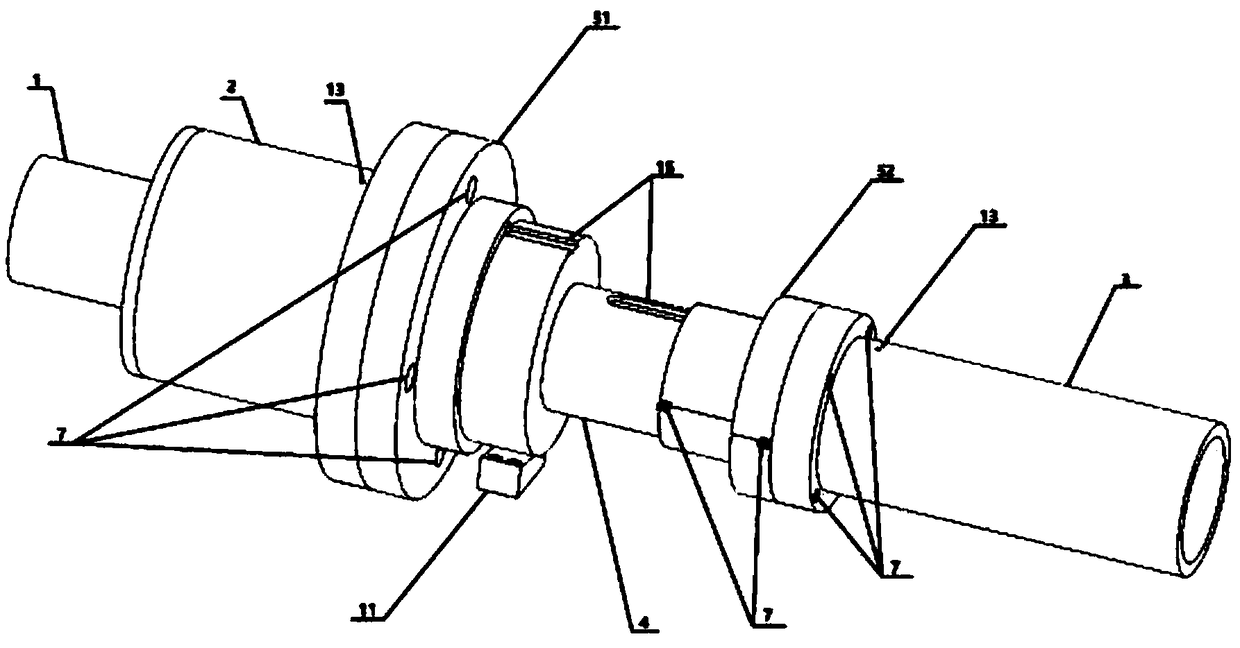

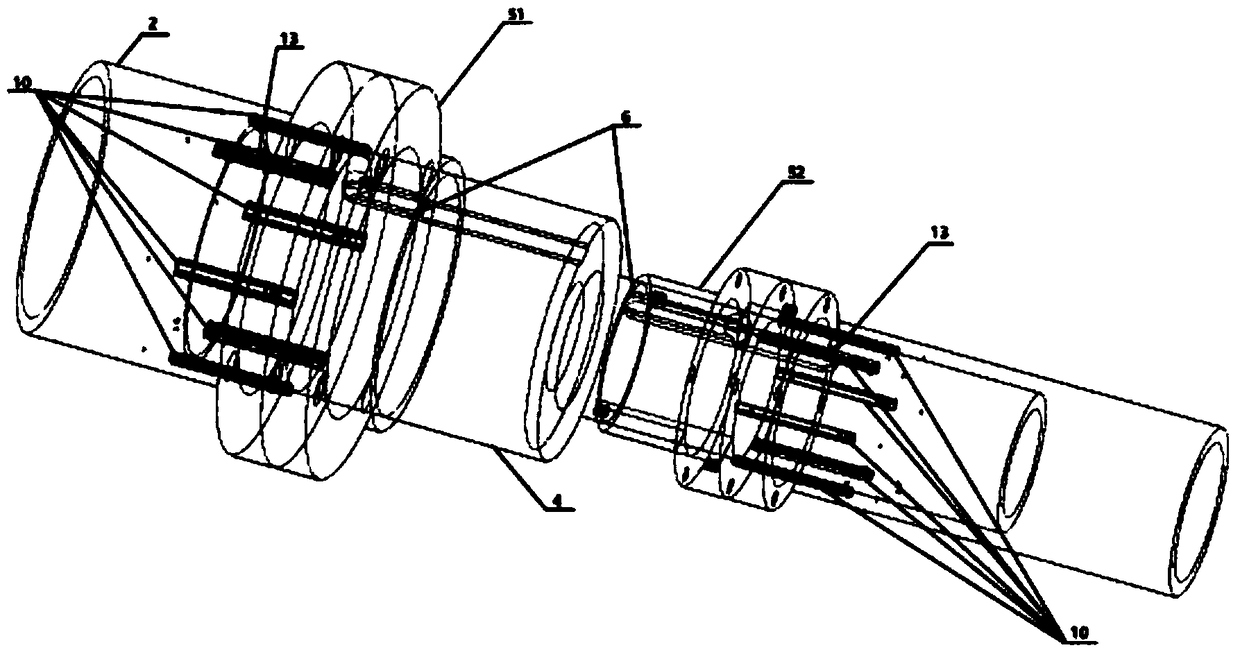

[0030] An infinitely variable intake system for an internal combustion engine, comprising an intake manifold 1, a resonance box shell 2, an intake manifold outer pipe 3, a connecting pipe 4, a flange, a feather key 6, bolts, washers, and sealing gaskets , Slider guide rail device, screw slider 11 and drive device. The driving device includes a servo motor 16 and a reduction gear set controlled by the ECU. The driving device and the screw slider device 11 are fixed to the outside of the resonance box shell 2 and the outer pipe 3 of the intake manifold through a bracket. There are two kinds of flanges, which are respectively used for the fixed connection between the connecting pipe 4 and the resonance box shell 2 and the outer pipe 3 of the intake manifold.

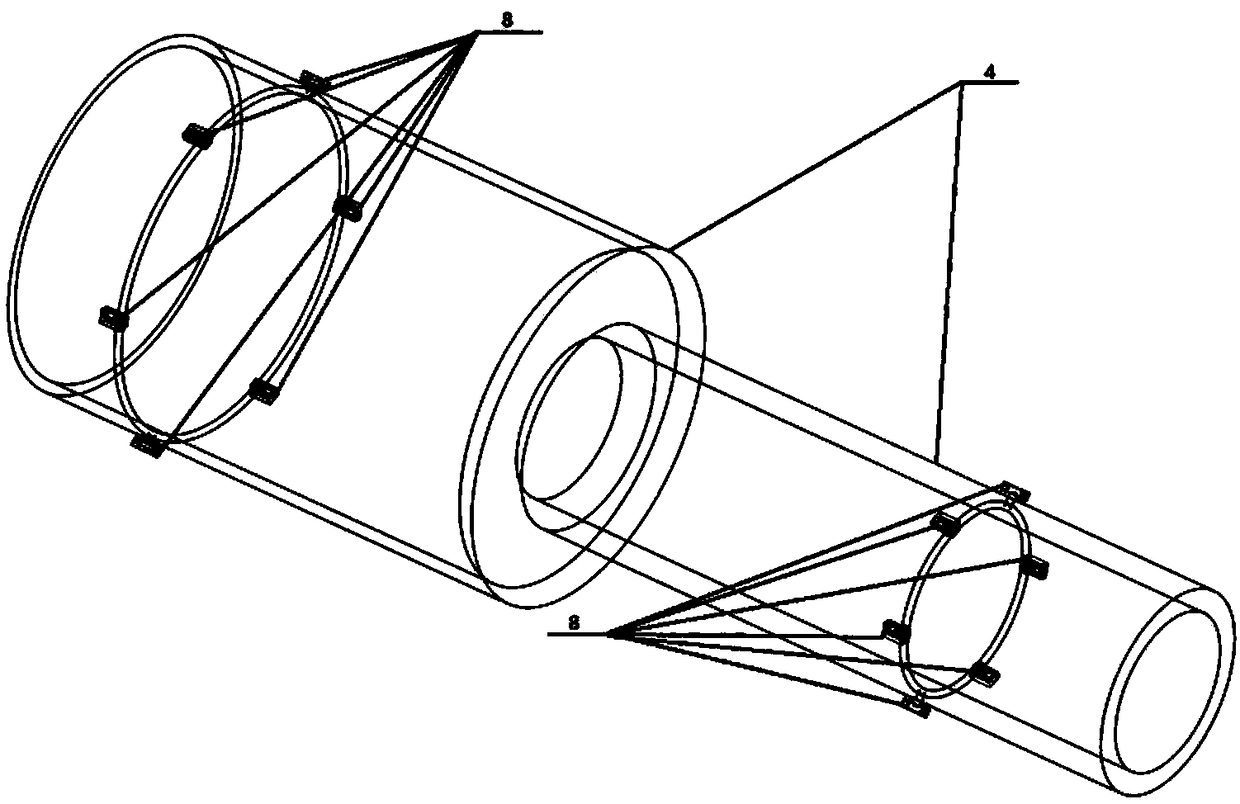

[0031] A slider 8 is installed at the front and rear of the connecting pipe 4 to guide the axial movement of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com