Method for opening and closing double-layer valve element assembly of pipeline valve

A technology of pipeline valves and assemblies, applied in the direction of control valves, valve devices, functional valve types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

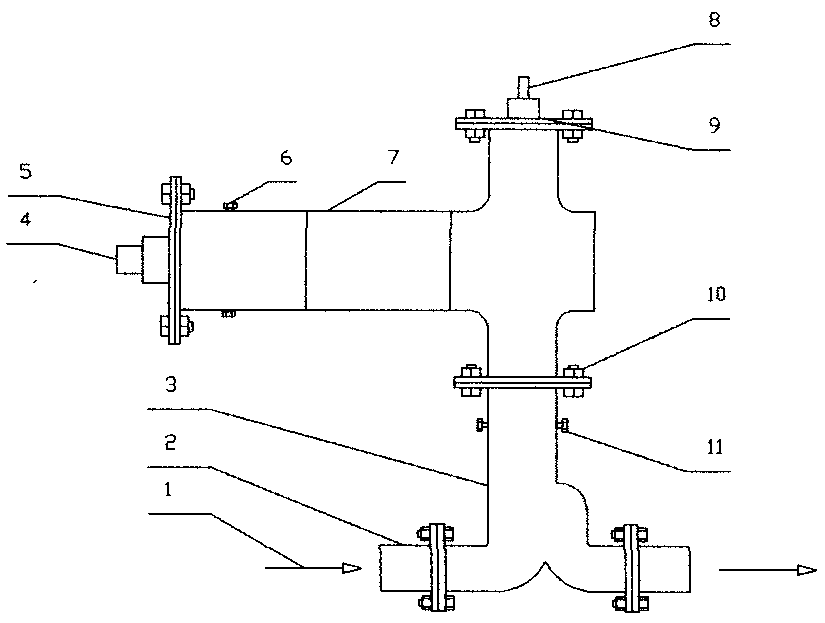

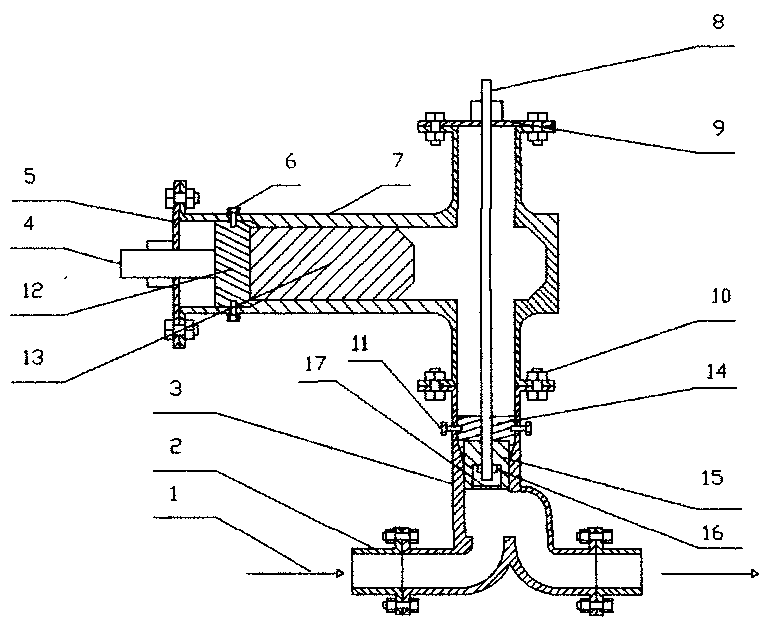

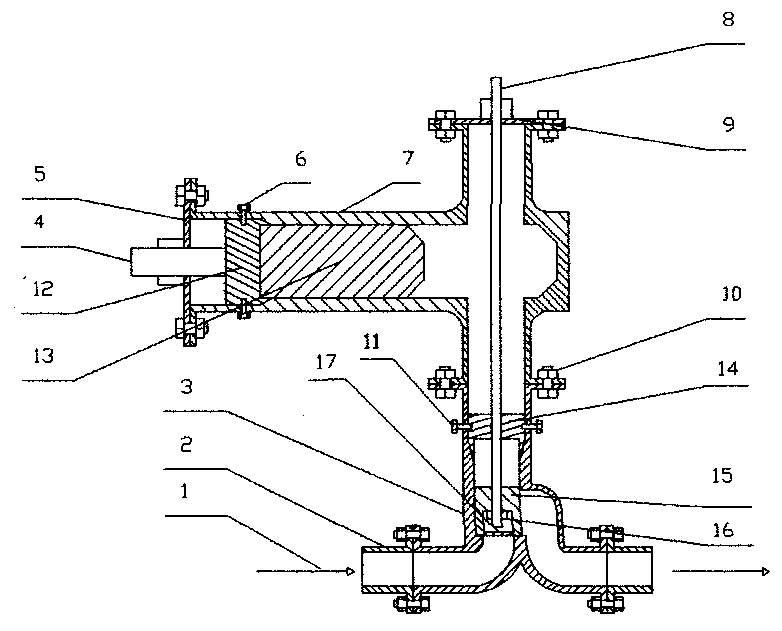

[0017] The opening and closing method of the pipeline valve double-layer spool assembly of the present invention is realized in this way. The opening and closing method of the combination of the layered spool cylindrical valve and the double-layered spool check valve will be described in detail below in conjunction with the accompanying drawings.

[0018] The pipeline valve double-layer spool assembly of the present invention adopts the structure of the pipeline double-layer spool cylinder valve and the double-layer spool check valve assembly structure; see figure 1 1. The structure of the pipeline double-layer spool cylinder valve and the double-layer spool check valve combination consists of: medium 1, pipeline 2, double-layer spool check valve body 3, double-layer spool cylinder valve stem 4, double-layer valve core Double-layer spool cylindrical valve bonnet 5, double-layer spool cylindrical valve positioning bolt 6, double-layer spool cylindrical valve body 7, double-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com