Atmosphere protection roller kiln

A roller kiln and atmosphere technology, applied in the field of heat treatment equipment, can solve problems such as the generation of condensate, the consumption of protective gas, and the impact on production capacity that cannot be fundamentally solved, so as to reduce the impact, reduce energy consumption, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

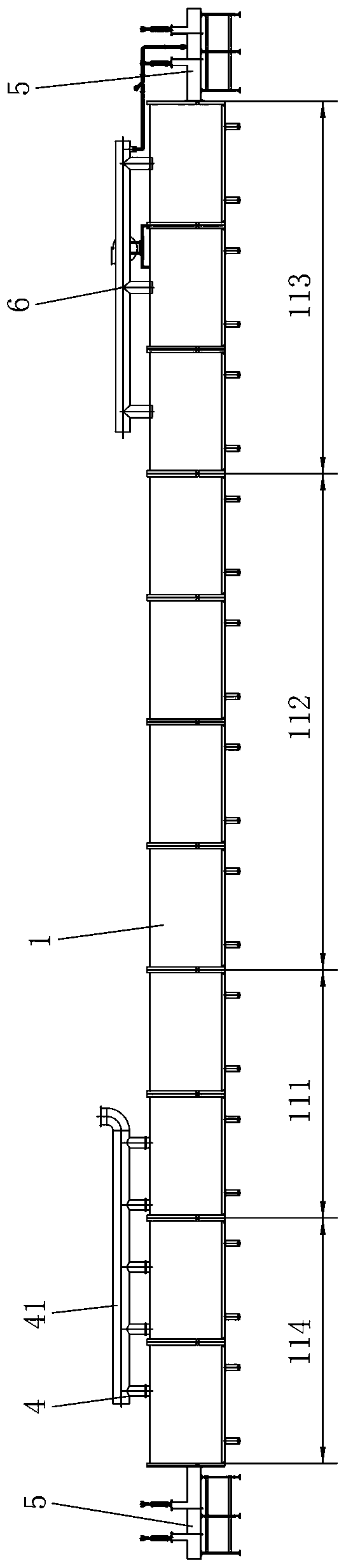

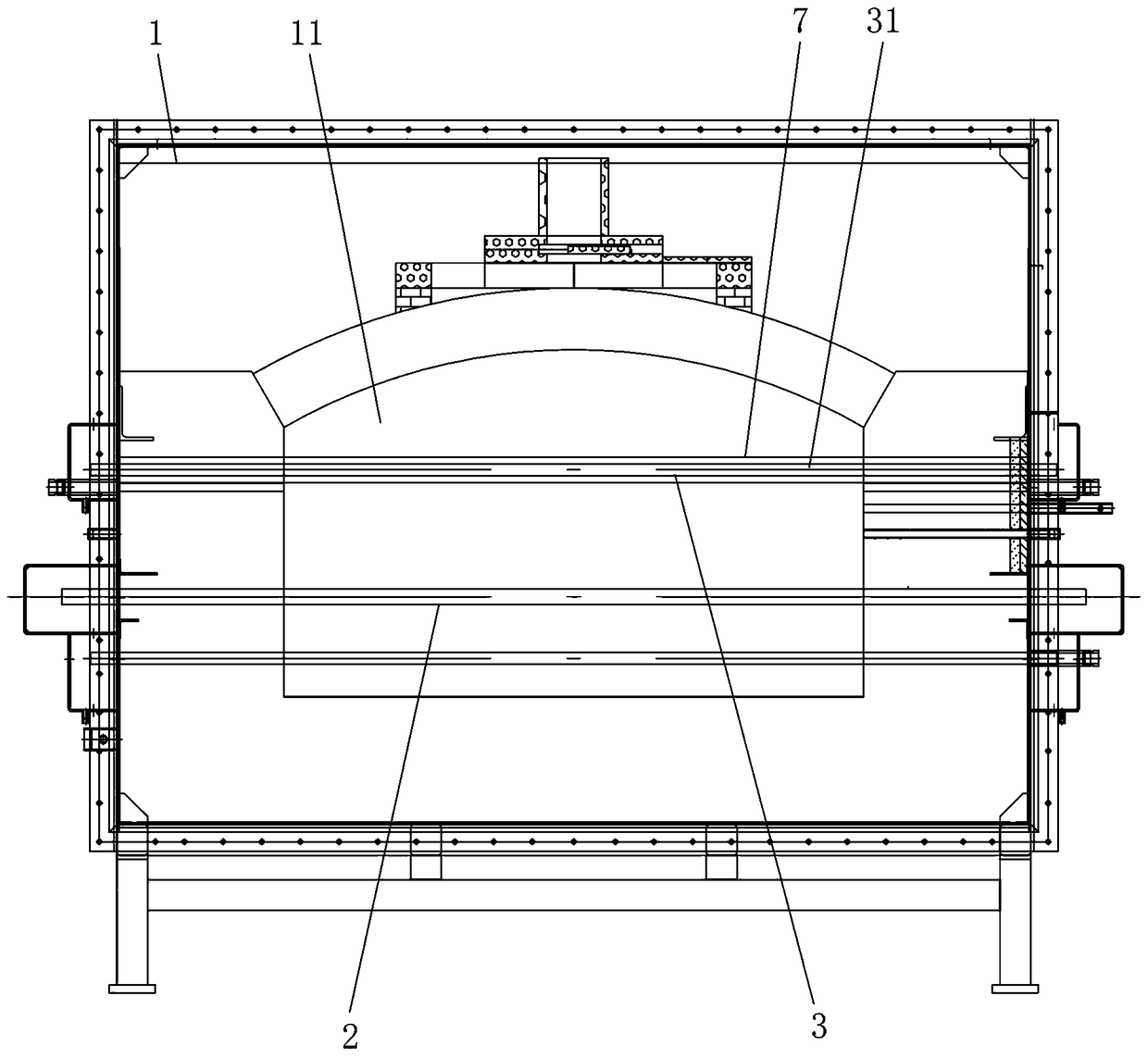

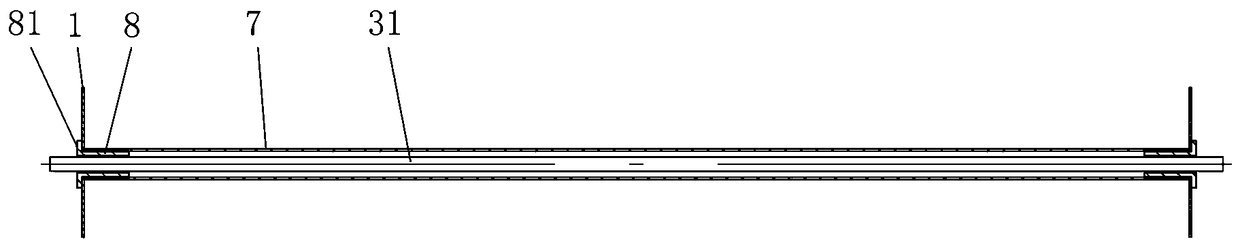

[0024] Such as figure 1 and figure 2 As shown, the atmosphere-protected roller kiln of this embodiment includes a furnace body 1 having a furnace 11, a material conveying device 2 arranged in the furnace 11, and a first device connected to the furnace 11 for introducing protective gas into the furnace 11. Intake device (not shown in the figure), the furnace 11 is divided into a heating section 111, a constant temperature section 112 and a cooling section 113 along the direction from the inlet to the outlet. The heating section 111 and the constant temperature section 112 are provided with heating devices 3. The furnace 11 is also provided with a smoke exhaust section 114 , the smoke exhaust section 114 is located between the heating section 111 and the inlet of the furnace 11 , and the smoke exhaust section 114 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com