Heat Exchanger

A technology of heat exchangers and heat exchanger fins, applied in heat exchanger sealing devices, heat transfer modification, heat exchange equipment, etc., can solve the problems of easy corrosion of heat exchangers, reduce the corrosion resistance of heat exchangers, etc., and achieve Effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below, but the present invention can be implemented in a variety of different ways of claims;

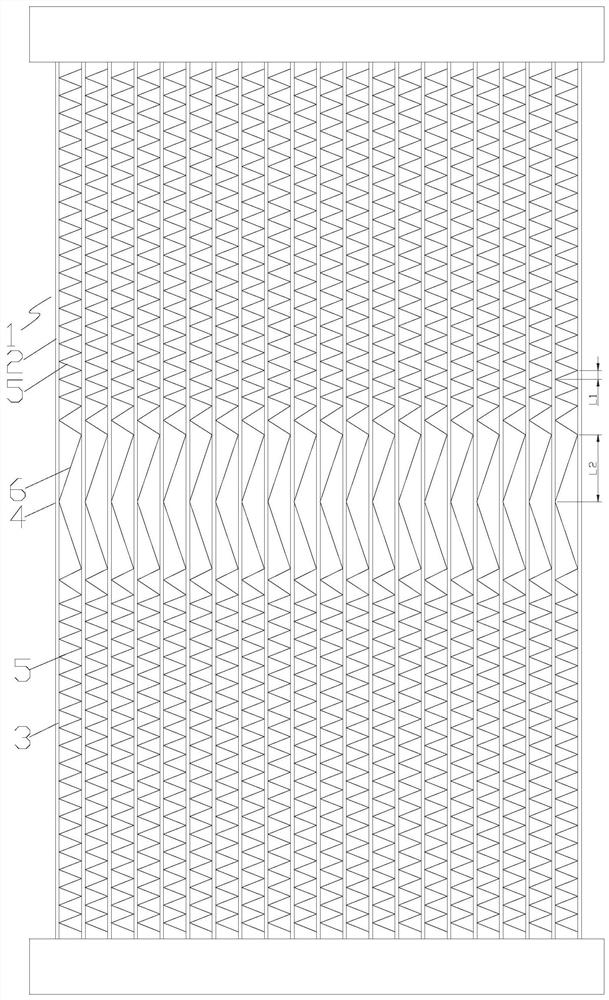

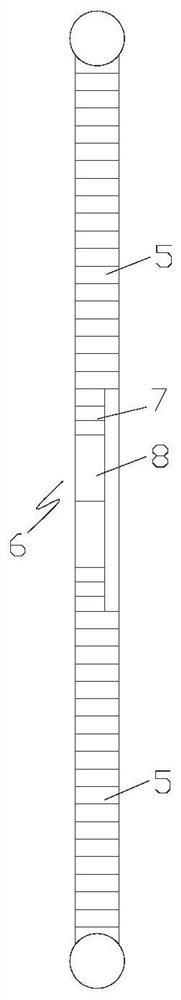

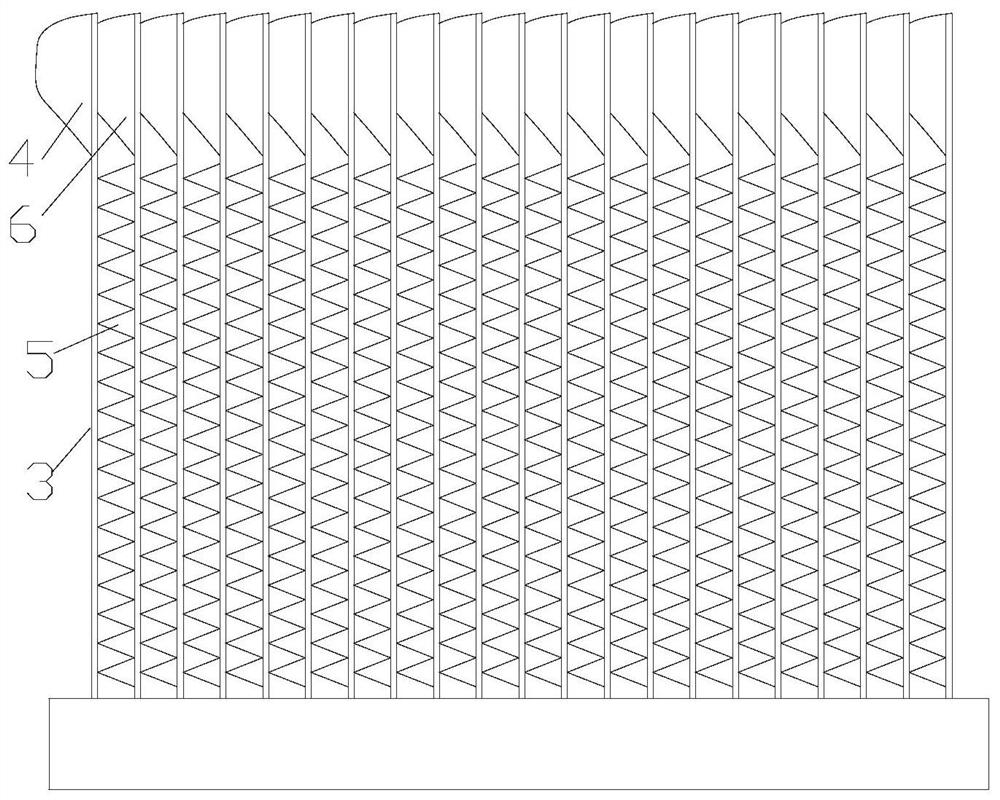

[0026] Please refer to Figure 1 to 17 As shown, according to an embodiment of the present invention, the heat exchanger includes a plurality of flat tube 1 arranged in a width direction, and the flat tube 1 includes a first straight tube section 2 and a second straight pipe section 3 located at both ends, and connected in the first The bending section 4 between the tube segment 2 and the second straight pipe section 3, between the adjacent first straight pipe segments 2 and between the adjacent second straight pipes 3, respectively, respectively, the first heat exchange sheet 5, bend The tube section 4 is provided with a second heat exchange sheet 6 having a low potential than the flat tube 1.

[0027] The heat exchanger of the present invention is provided at the position of the casing section 4 of the flat tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com