Intelligent manipulator, bidirectional walking mechanism thereof and full-automatic intelligent vending device

An intelligent manipulator and manipulator technology, applied in the field of coin-operated equipment or similar equipment, can solve the problems of high structural design requirements of vending machines, occupying the internal space of vending machines, and reducing the number of goods displayed, so as to save goods display space and maintain Convenience, avoiding the effect of falling and damaging the goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

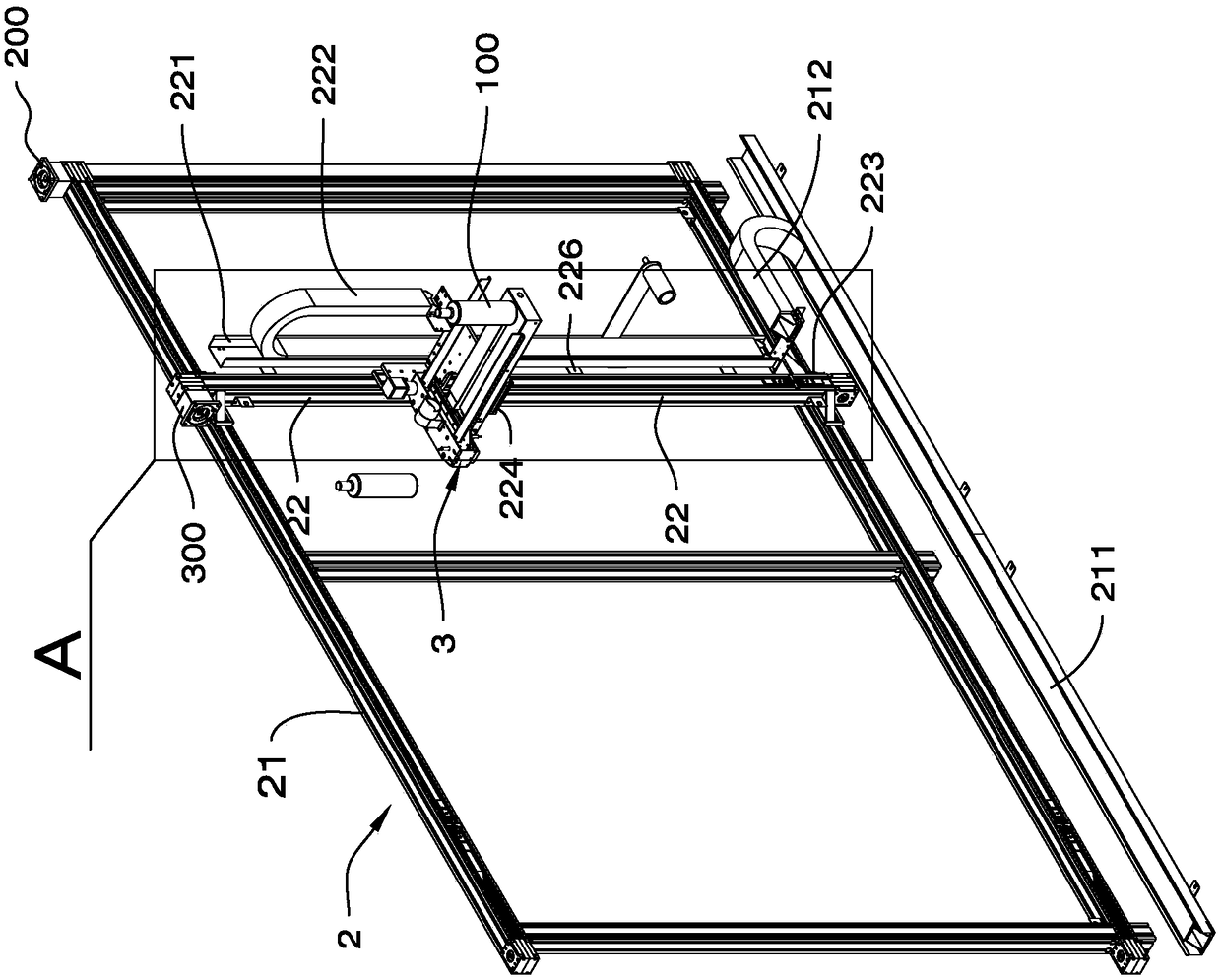

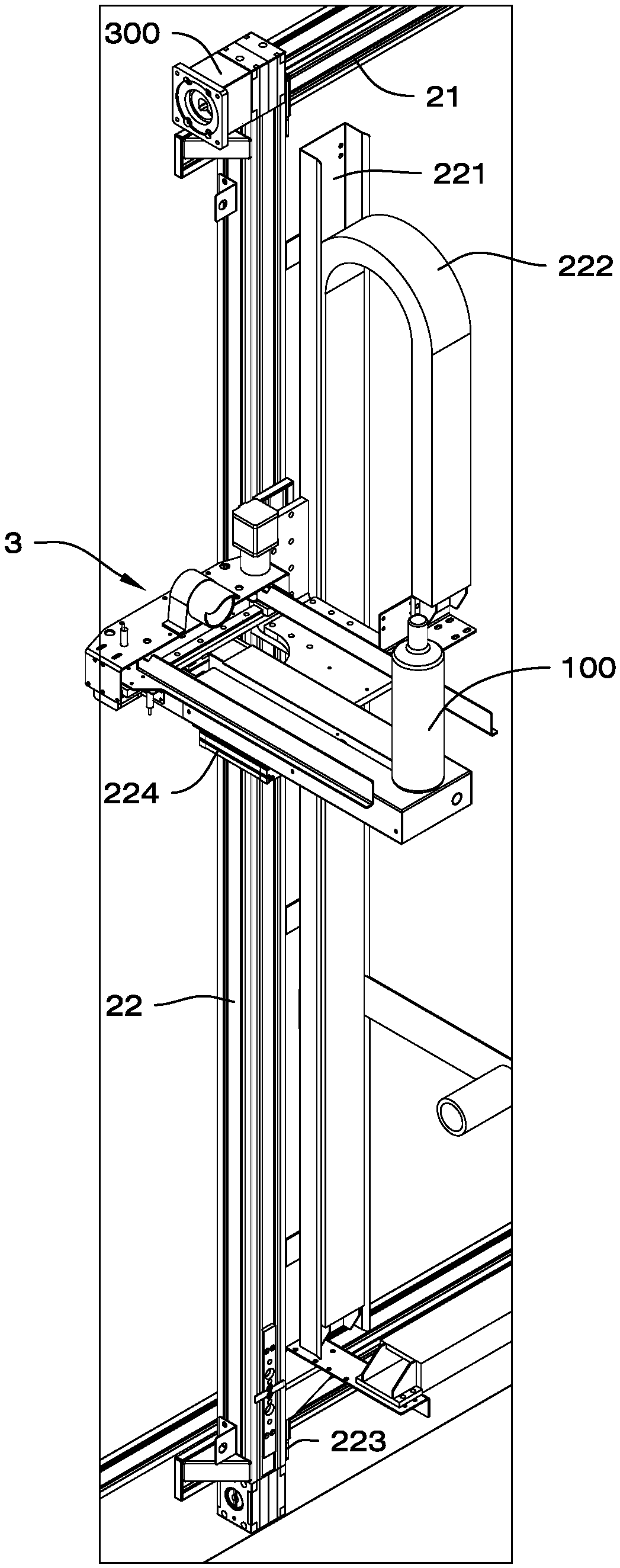

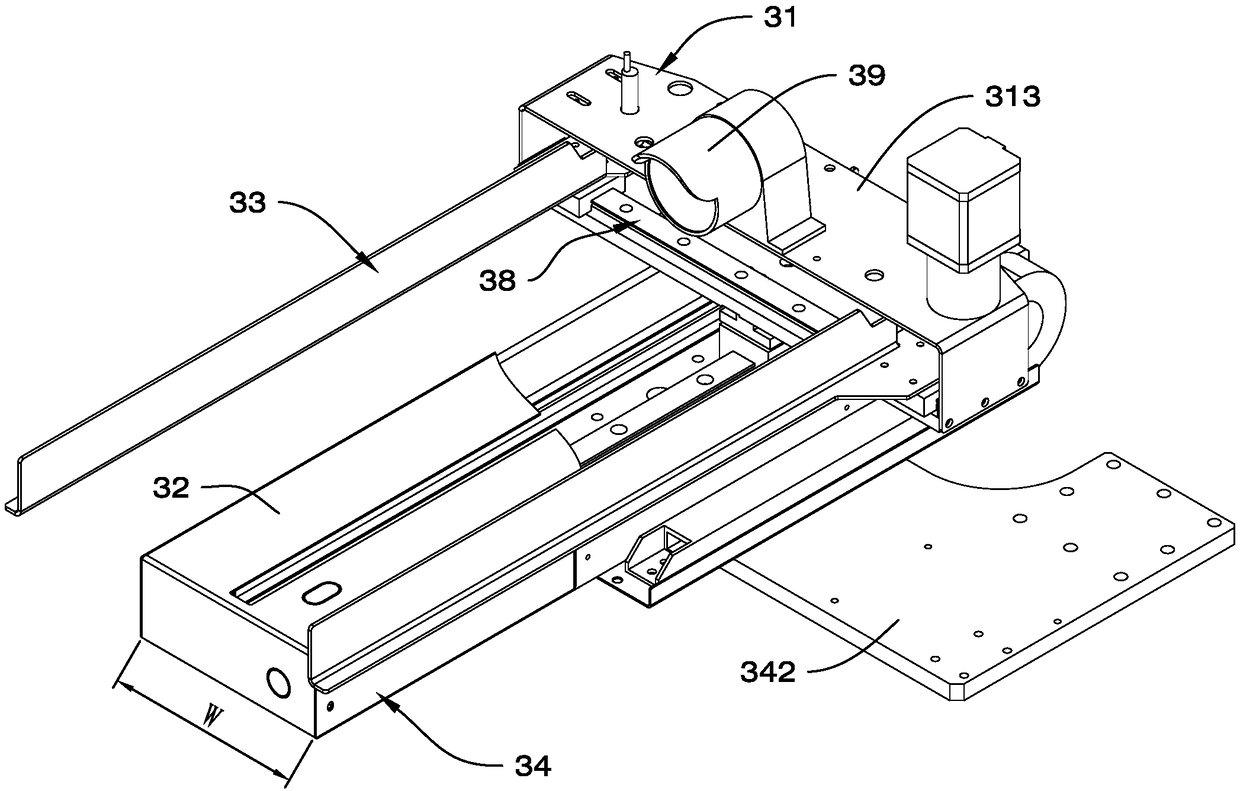

[0034] Such as Figure 7 , Figure 8 As shown, the automatic intelligent vending device of the present invention includes a two-way traveling mechanism 2 and an intelligent manipulator 3. The above-mentioned two-way (X-direction, Y-direction) traveling mechanism 2 is arranged on the rear side of the shelf unit 1, and the electronic control system is located between the shelf units 1. in the control cabinet. The above-mentioned two-way walking mechanism 2 includes two X-direction linear modules 21 arranged in parallel up and down and a Y-direction linear module 22 vertically connected between the two X-direction linear modules 21, and the Y-direction linear module 22 can move along the The X-direction linear module 21 reciprocates, and the Y-direction linear module 22 is provided with an intelligent manipulator 3 , which can reciprocate on the Y-direction linear module 22 .

[0035] Such as figure 1 , figure 2As shown, the two-way walking mechanism 2 includes an X-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com