A laser gain fiber cooling device

A technology of cooling device and gain fiber, which is applied in the direction of laser cooling device, laser, laser parts, etc., to achieve the effects of uniform temperature, uniform flow and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

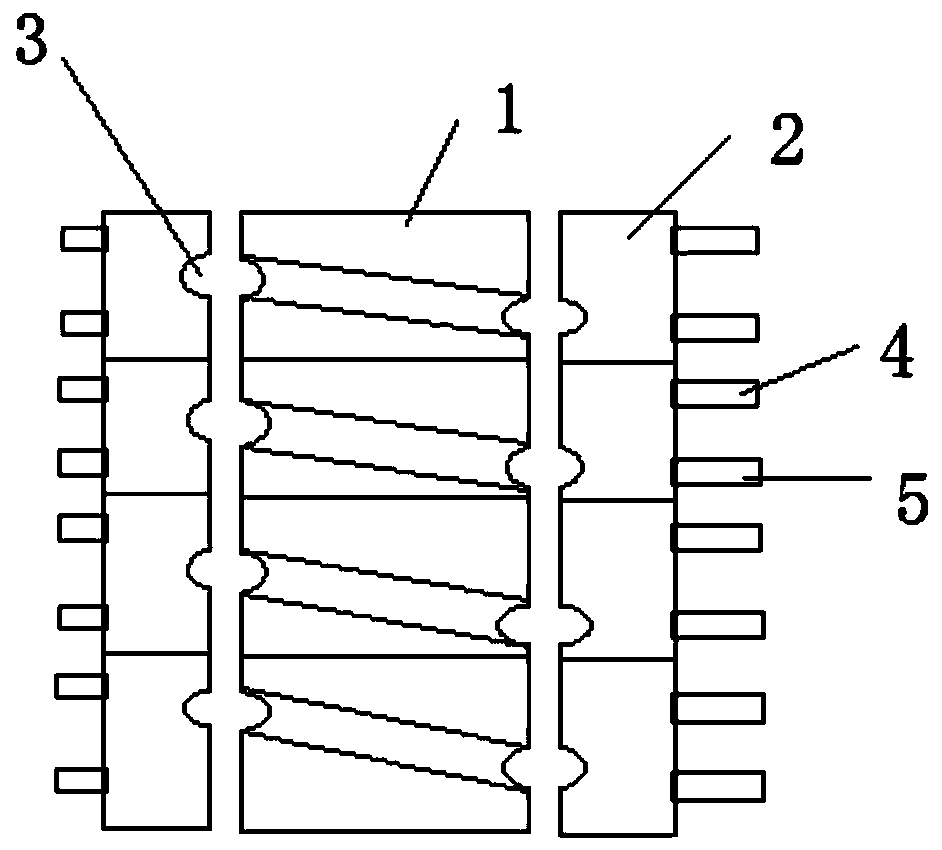

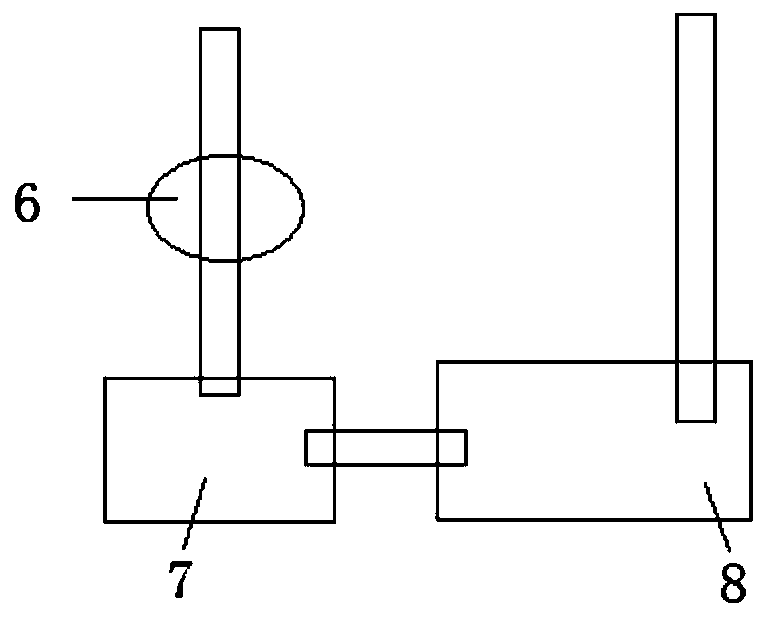

[0027] A laser gain fiber cooling device, the device comprises a cooling pipe with a spiral fiber groove on the outer surface and a cooling cover with a spiral fiber groove 3 on the inner surface, the gain fiber is spirally wound around the cooling pipe along the fiber groove 3, the The cooling pipe is formed by connecting a plurality of cooling sub-pipes 1, the cooling sub-pipes 1 contain cooling liquid, and each cooling sub-pipe 1 includes an independent cooling liquid circulation channel, and the cooling liquid circulation channel includes a cooling liquid input channel 4 , the output channel 5, the heat dissipation part 7, the cooling cover is buckled on the surface of the cooling pipe, it includes a plurality of semi-circular cooling sub-covers 2, the cooling sub-cover 2 encapsulates the cooling liquid, and each cooling sub-cap 2 includes an independent cooling liquid A circulation channel, the cooling liquid circulation channel includes a cooling liquid input channel 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com