A laser treatment system using thulium-doped optical fiber

A laser treatment, fiber optic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

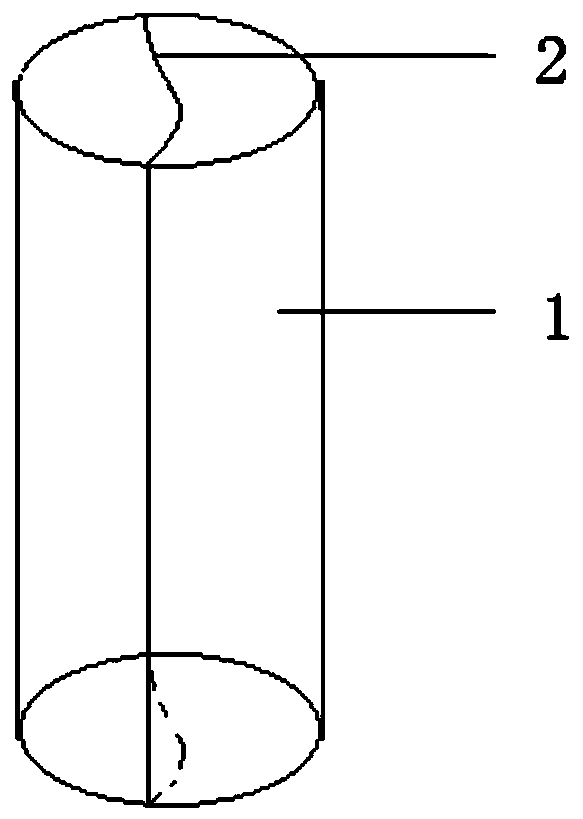

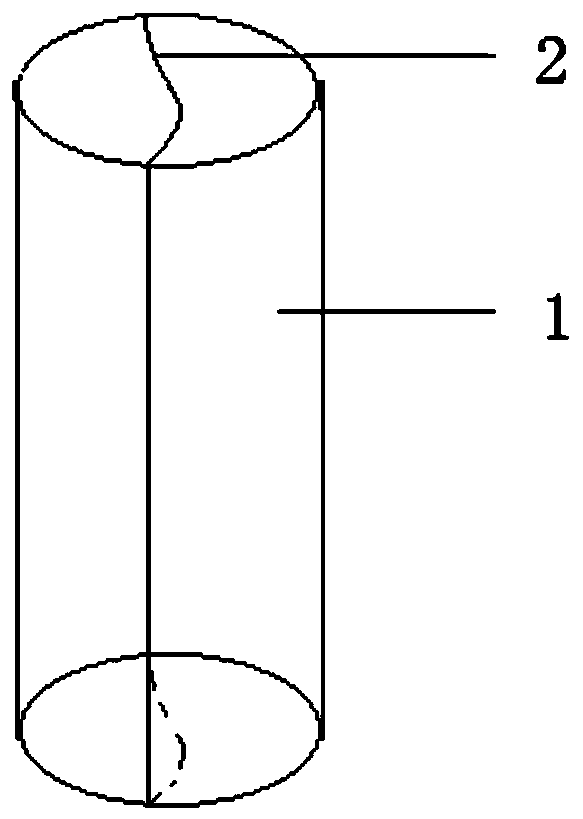

[0048] Such as figure 1 As shown, the present invention provides a laser treatment system using a thulium-doped fiber, the system includes a laser, a cooling system, a control system, a safety protection system and an operation fiber, the gain fiber of the laser is a thulium-doped fiber, and the doped The thulium optical fiber includes a doped core 1 and a cladding layer sheathed on the surface of the core. The doped core forms a low-doped passage 2 from the center to the outside. The cooling system includes multiple independent cooling liquid circulation circuits.

[0049]The low-doped passage 2 forms a curve through the center on the cross-section of the core.

[0050] The cooling liquid circulation channel includes a cooling liquid input channel, an output channel, and a cooling part. The flow rate of coolant in each independent coolant circulation system can be adjusted independently.

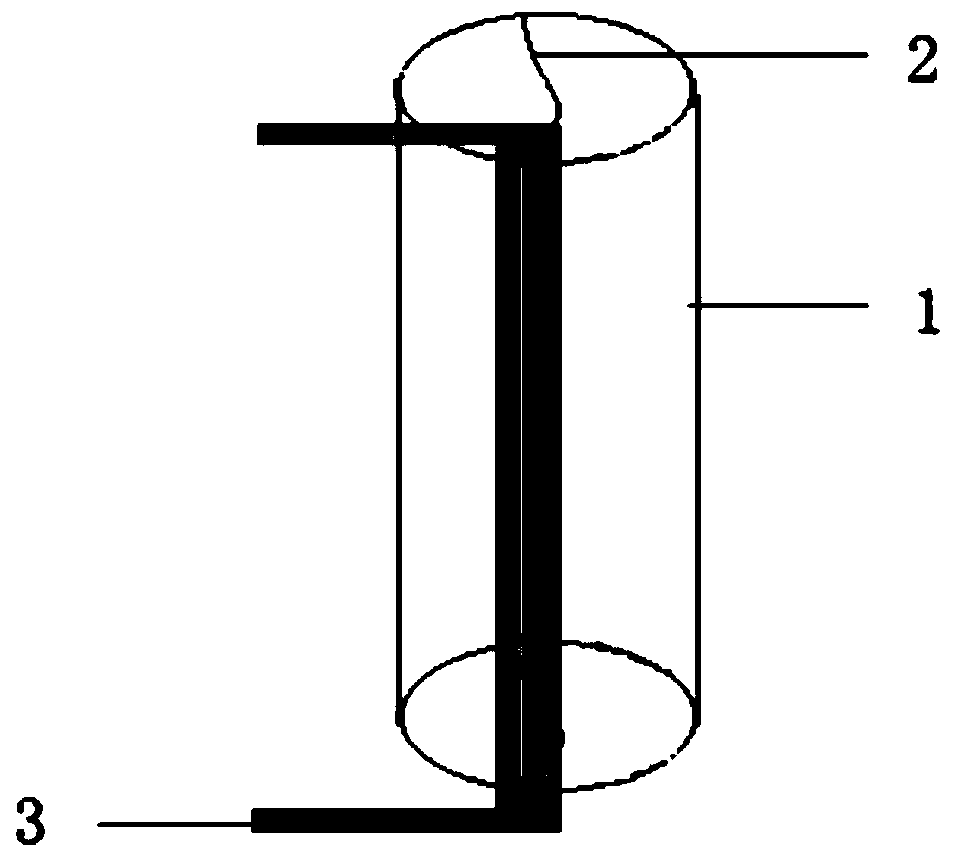

[0051] Such as figure 2 As shown, a separate cooling liquid circulation channel 3 i...

Embodiment 2

[0074] Such as figure 1 As shown, the present invention provides a laser treatment system using a thulium-doped fiber, the system includes a laser, a cooling system, a control system, a safety protection system and an operation fiber, the gain fiber of the laser is a thulium-doped fiber, and the doped The thulium optical fiber includes a rare earth doped core 1 and a cladding covering the surface of the core. The doped core 1 forms a low-doped passage 2 from the center to the outside. The cooling system includes multiple independent cooling liquid circulation circuits.

[0075] The low-doped passage 2 forms a curve passing through the center on the cross-section of the core 1 .

[0076] The cooling liquid circulation channel includes a cooling liquid input channel, an output channel, and a cooling part. The flow rate of coolant in each independent coolant circulation system can be adjusted independently.

[0077] Such as figure 2 As shown, a separate cooling liquid circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com