Optoisolator with bandwidth of 1 mu m

An optical isolator and bandwidth technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of unstable characteristics and damage to the LD light source unit, and achieve polarization independence, miniaturization, and improvement of magnetic flux density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

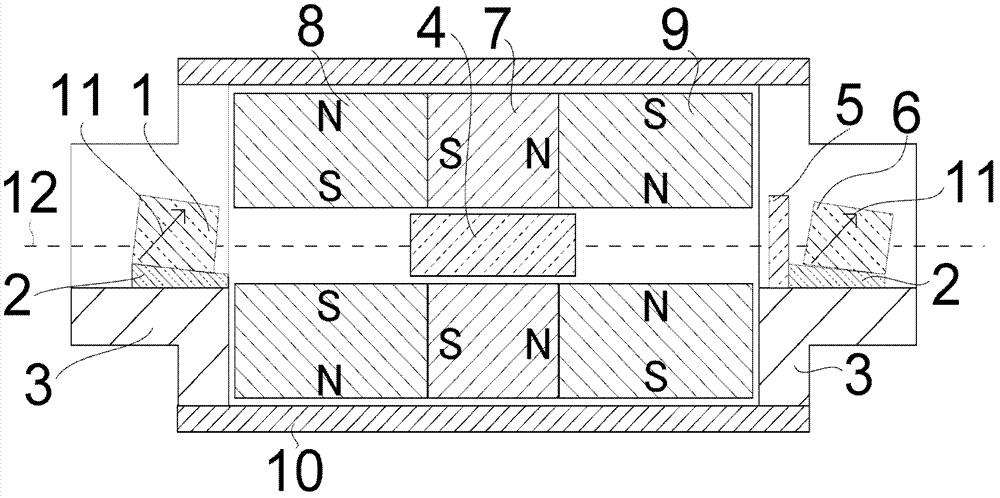

[0197] produced as figure 1 A 1μm bandwidth optical isolator constructed as shown.

[0198] The incident polarizer 1 and the outgoing polarizer 6 use rutile single crystal, and the light transmission surface thereof is processed into a parallel plate with a thickness of 1.0 cm, and the optical axis 11 is inclined 47.8 degrees relative to the optical axis 12 . figure 1 The direction of inclination depicted in is toward the inside of the paper. In addition, an anti-reflection film with a center wavelength of 1.06 μm was applied to the light transmission surface of the flat-plate polarizer. At the same time, in order to prevent the reflected light from the light transmission surface from returning to the incident light path, the bottom surface of the polarizer was adhered. It is fixed on the wedge glass 2 with an inclination angle of only 5 degrees, and loaded on the polarizer bracket 3.

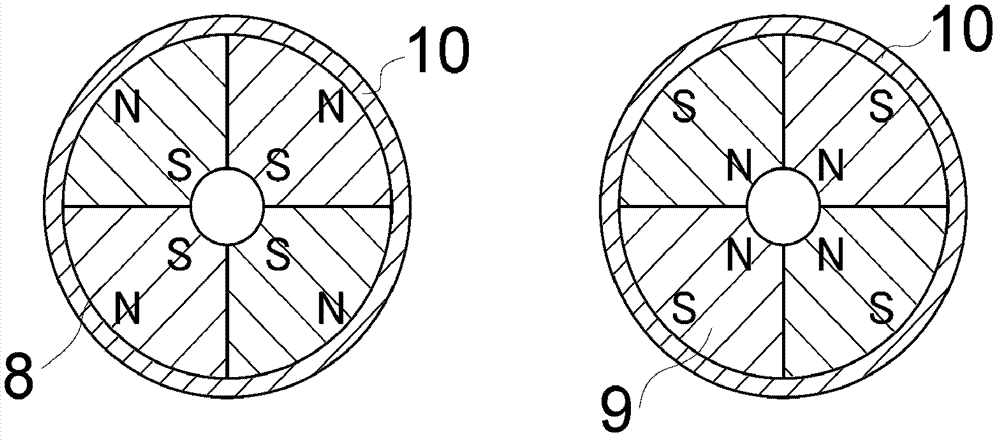

[0199] And, let the Faraday rotator 4 be located at the central position of the hollow po...

Embodiment 2 and 3

[0205]In the above formula (I), the correspondence relationship between the Tb content x (0.5 to 1.0) and the Verdet constant was examined. As Example 2, (Tb 0.5 Y 0.5 ) 2 o 3 The same procedure as in Example 1 was carried out except for the single crystal of the oxide.

[0206] Furthermore, as Example 3, Tb containing the same weight % and x=1.0 was used 2 o 3 Except for the single crystal of the oxide, it was carried out in exactly the same manner as in Example 1.

[0207] The Verdet constant of a single crystal having the above composition was measured. It can be seen from the results that its Verdet constant is: when x=0.5, 0.27min / (Oe*cm); when x=1.0, 0.43min / (Oe*cm). In addition, in Examples 2 and 3, the extinction ratios were both 35 dB.

[0208] When changing the sample length (optical path length) of the single crystals used in Examples 1 to 3 at intervals of 0.1 cm within the range of 0.7 to 1.1 cm, the magnetic flux density T when the Faraday rotation angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Field constant | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Insertion loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com