A tape machine control circuit for star a preset bell interlocking beside a tape machine

A control circuit and tape machine technology, applied in the field of electrical transmission, can solve problems such as potential safety hazards, cumbersome operation procedures, etc., and achieve the effect of preventing operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

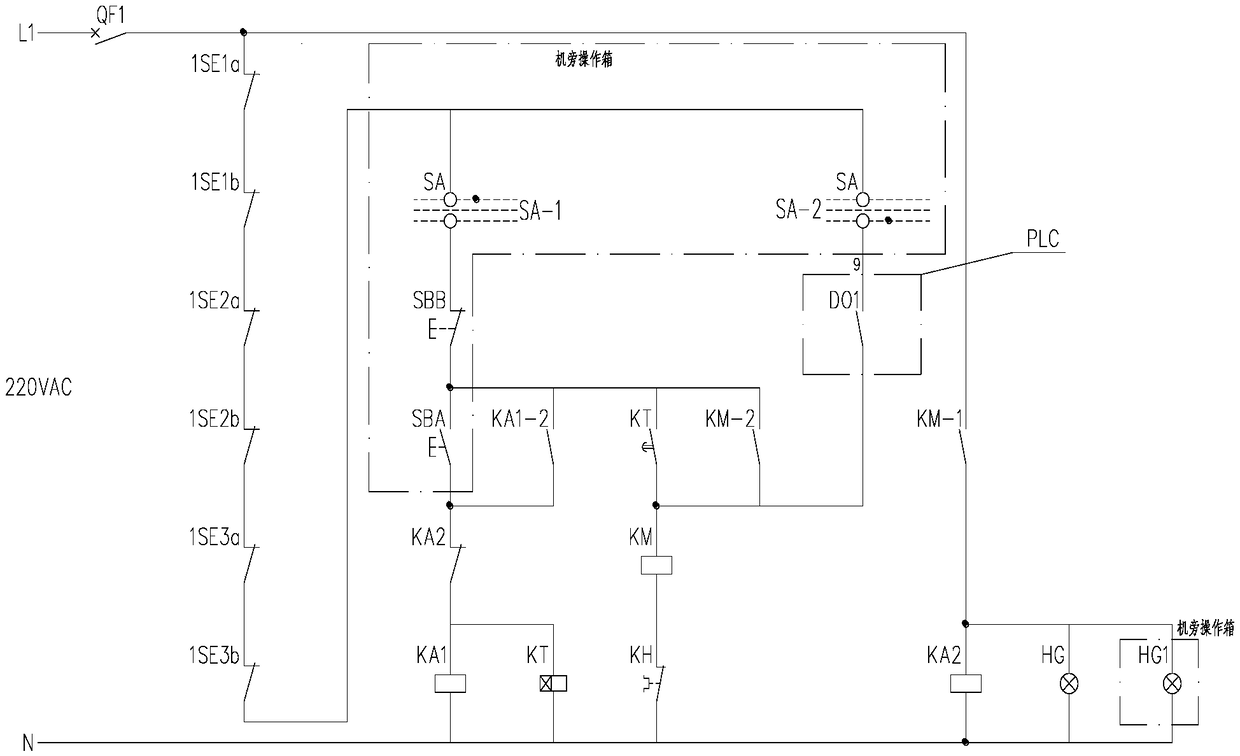

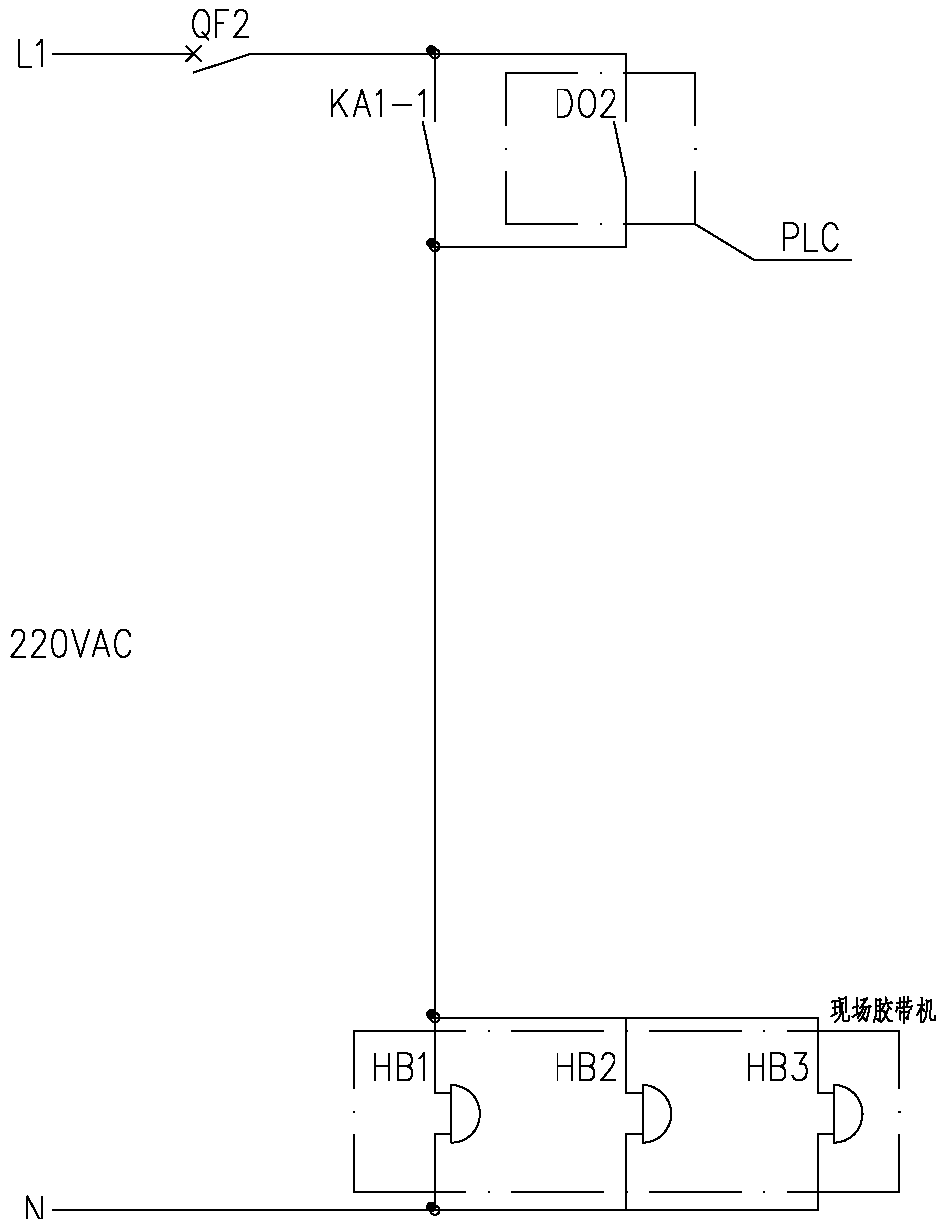

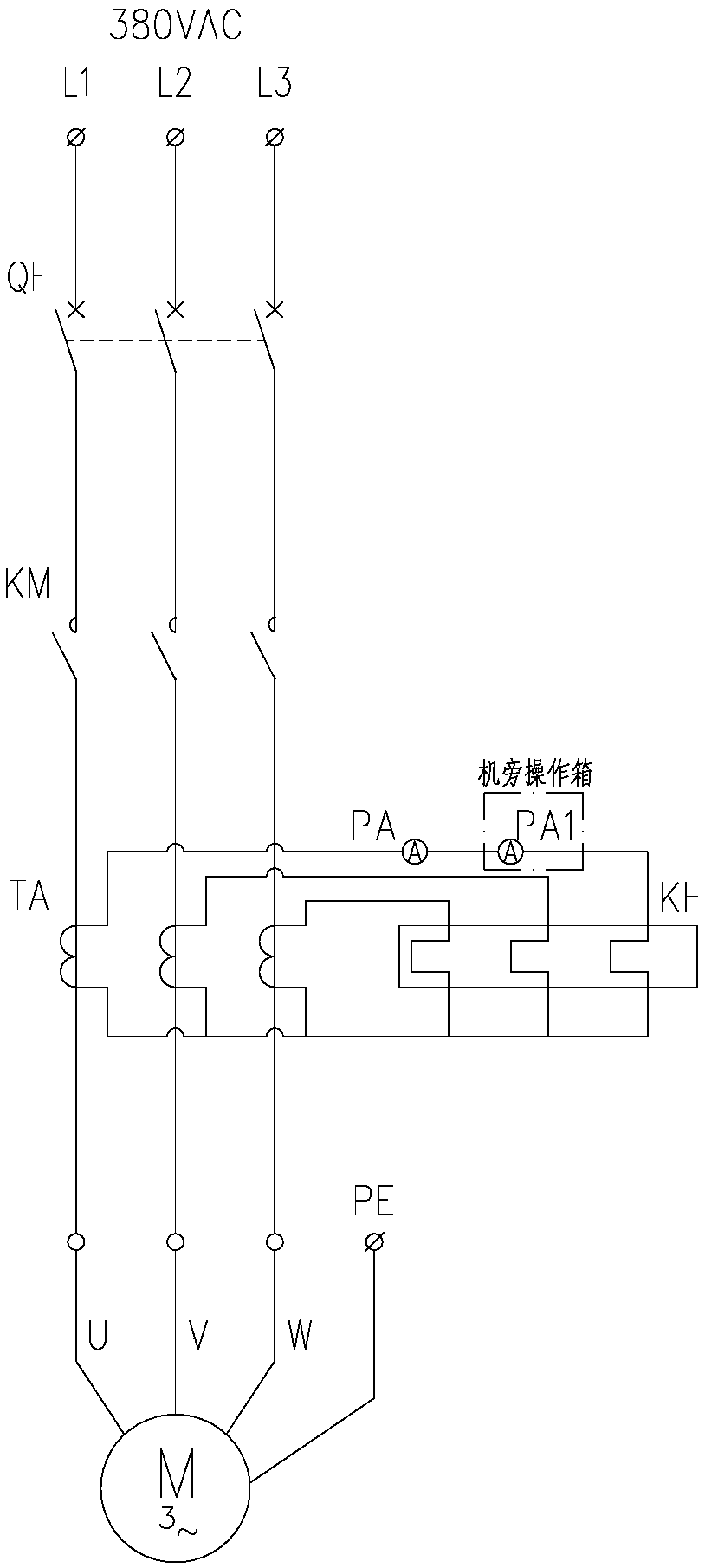

[0025] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-2 As shown, a tape machine control circuit with an interlocking warning bell starting next to the machine includes a tape machine contactor KM, a thermal relay KH, and on-site warning bells HB1-HB3. It also includes machine-side / centralized selection switch SA, machine-side start button SBA, machine-side stop button SBB, first intermediate relay KA1, second intermediate relay KA2 and time relay KT. On-site warning bells HB1-HB3 are alarm bells commonly used in electrical control.

[0027] The machine side / centralized selection switch SA includes the machine side control bit SA-1, the upper end of the machine side control bit SA-1 is connected to the 220V power supply L1, and the lower end is in turn connected with the machine side stop button SBB normally closed point, and the machine side start button SB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com