Novel material suction nozzle device

A material and a new type of technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of high failure rate, large volume and weight that cannot be equipped with multiple suction nozzles, uncontrollable speed and height, etc., to achieve high matching accuracy and improve operating efficiency. , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

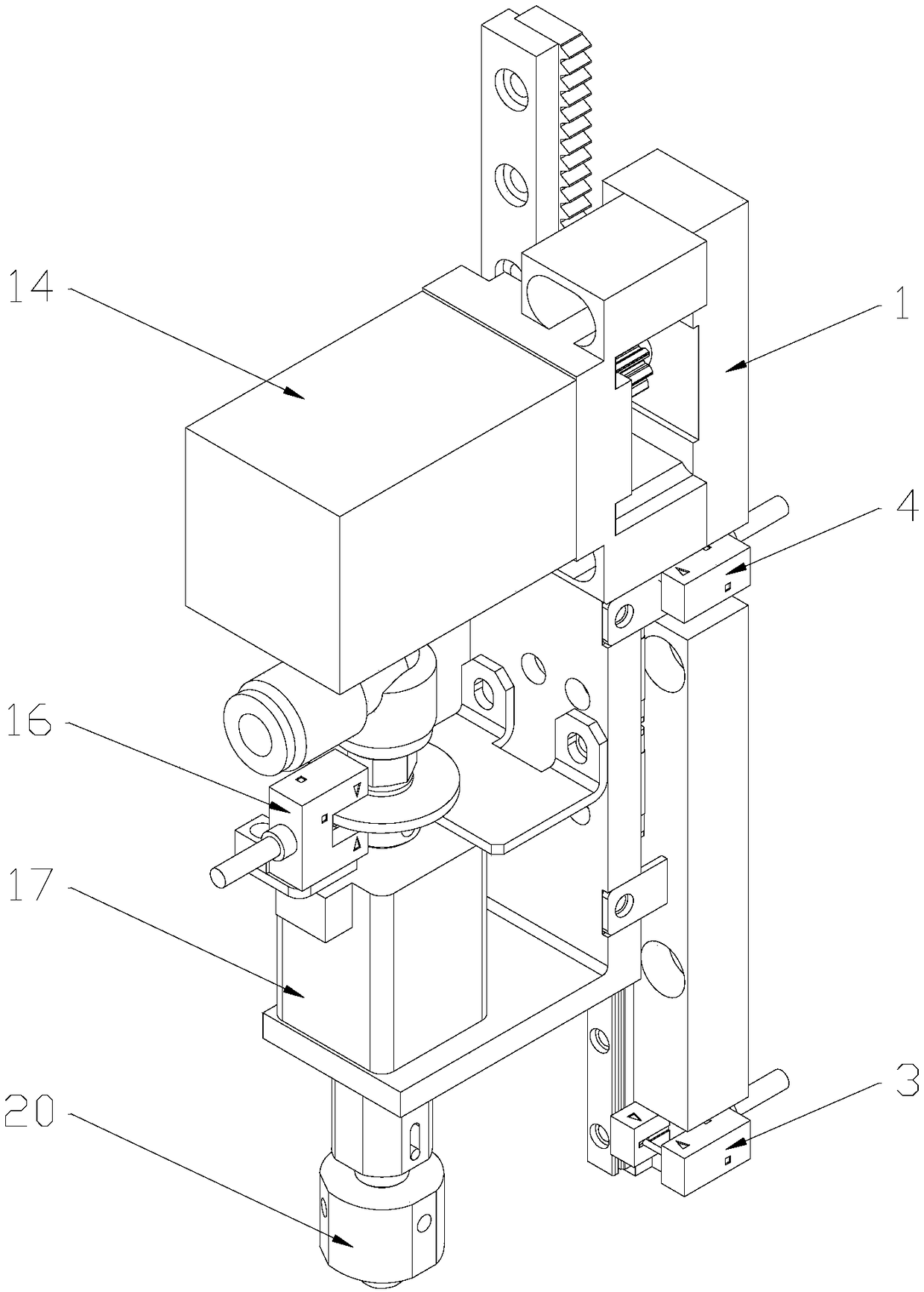

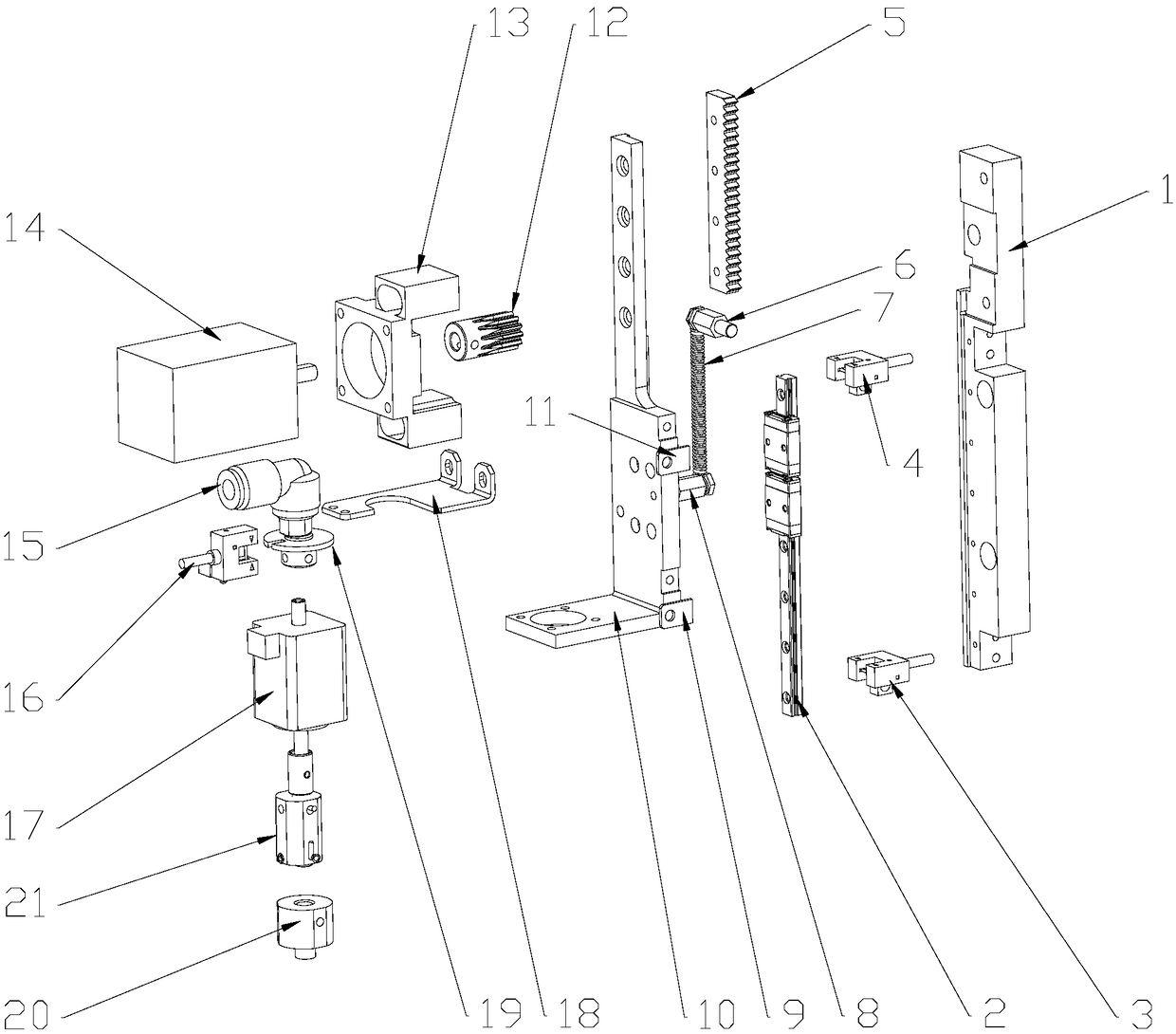

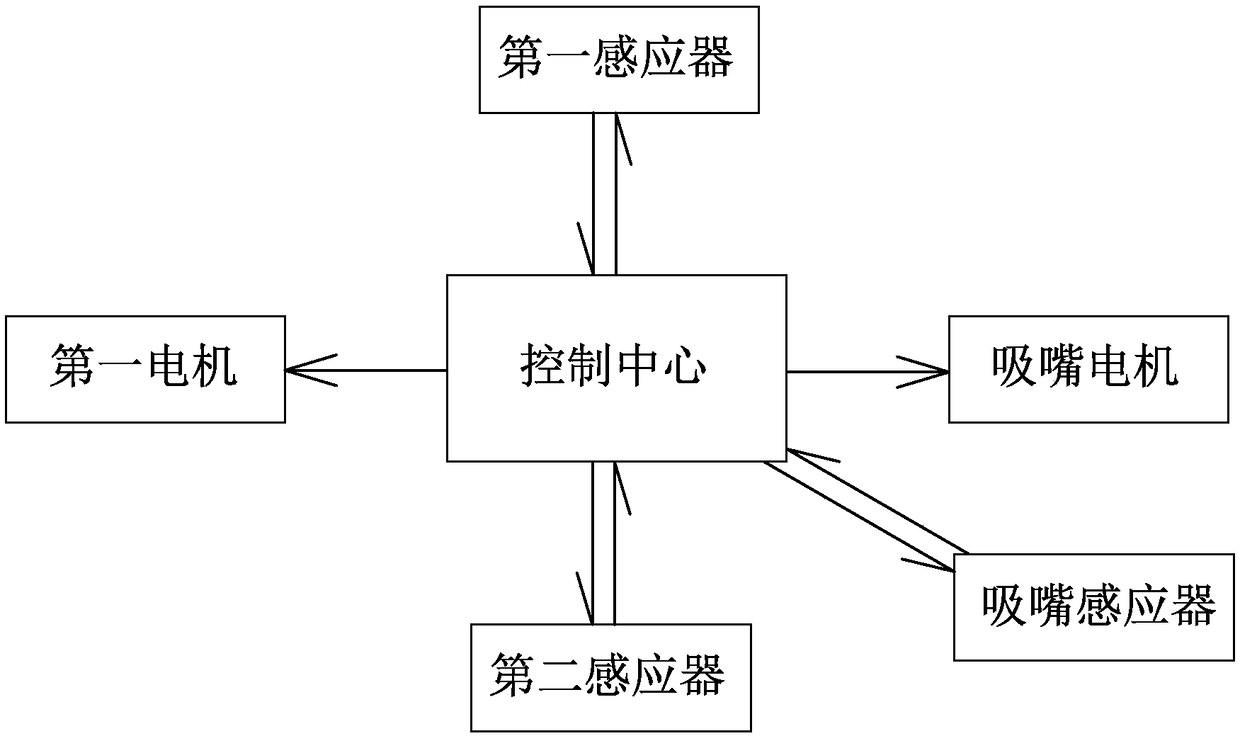

[0018] Such as Figure 1-Figure 3 As shown, a novel material suction nozzle device includes a main support 1, a vertical power device, a guide rail 2, a suction nozzle 20 device with a nozzle motor 17, and the vertical power device includes a motor mounting plate 10, a first motor 14 , the first motor mount 13, the gear 12 and the rack 5, the slide rail portion of the guide rail 2 is installed vertically on the main bracket 1, the motor mounting plate 10 is installed on the slider portion of the guide rail 2, and the rack 5 is installed vertically On the motor mounting plate 10, the shell of the first motor 14 is fixed on the first motor mounting base 13 and the first motor mounting base 13 is installed on the motor mounting plate 10. The rotor front end of the first motor 14 is equipped with a gear 12, gear 12 and the rack 5 cooperate with each other to drive the vertical power unit to move up and down. Therefore, the vertical power unit can slide up and down on the slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com