Spraying nozzle for removing fish scale through water jet flow

A technology of water jets and fish scales, which is applied in the direction of fish cleaning/descaling, spraying devices, spraying devices, etc., can solve the problems of reduced processing efficiency, sensory impact, difficult control, etc., to achieve uniform distribution of striking force and increase striking range , The effect of rapidly accelerating water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

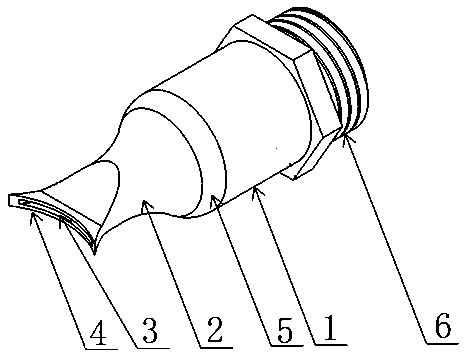

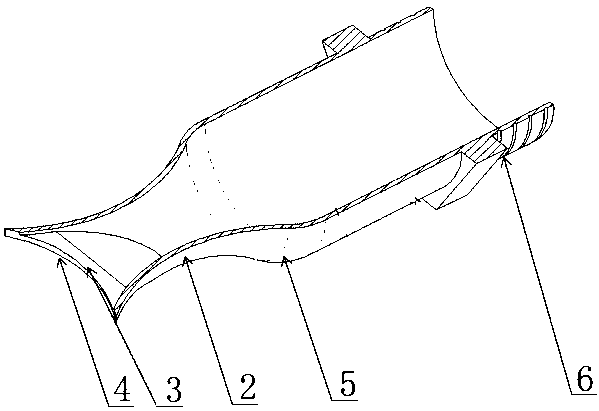

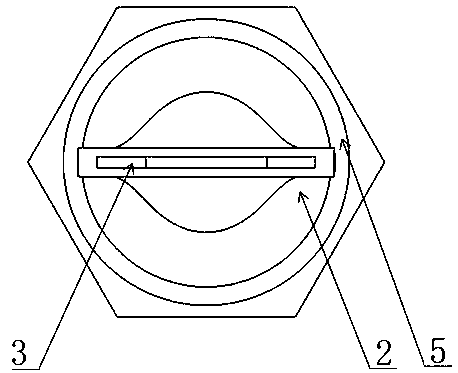

[0015] Such as Figure 1 to Figure 4 As shown, the nozzle used for water jet removal of fish scales, the water inlet chamber 1, the acceleration section channel 2 and the water outlet 3, the water inlet chamber 1, the acceleration section channel 2 and the water outlet 3 are connected together as a whole, and its center The axes are all on the same straight line, the water inlet chamber 1 is a cylindrical cavity, the hose and the water inlet chamber 1 are tightly connected by the connecting thread 6, the water flow enters from the water inlet 7, and flows to the acceleration section at a certain speed according to a given pressure. The channel moves quickly. In the entire internal cavity, the diameter of the water inlet chamber 1 is the largest, and its preferred value is 5mm-7mm; in addition, the length of the water inlet chamber 1-1 is preferably 10mm-12mm, and a section of the acceleration section channel 2 It is smoothly connected with the water inlet chamber 1 by a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com